1. Introduction Precast concrete walls are strong, reliable, and built for modern needs. They are made off-site and then moved to the job site for quick assembly. These concrete walls have changed how builders plan and complete projects. Concrete wall panels have been used for years to speed up construction. Today, precast concrete walls offer even more design choices. From homes to large buildings, these panels can handle tough conditions and still look great. What Are Precast Concrete Walls? Precast concrete walls are factory-made. They use molds that shape precast concrete panels before they harden. This results in exact sizes and finishes. Builders often call them prefab concrete walls or prefabricated concrete walls because they arrive ready to install. These wall concrete panels help projects run smoothly. Workers place them quickly, reducing labor time. They also cut down on waste at the construction site. Historical Evolution In the past, people built walls using blocks or poured concrete. But precast concrete wall panels changed the game. Early users saw how fast and sturdy these panels were. Over time, better materials and methods have led to lighter, stronger, and more appealing concrete walling solutions. 2. Benefits and Unique Advantages 2.1 Speed and Efficiency Faster Construction TimelinesFactory-made panels arrive ready to install. They match project specifications and reduce the time spent measuring and cutting on-site. This also lowers the risk of human error in assembly. By cutting down on lengthy formwork, curing, or extensive scaffolding, the entire construction process becomes smoother and more predictable. As a result, contractors can meet tight deadlines with fewer delays, ensuring projects stay on budget and on schedule. Minimized Weather DelaysSince concrete wall panels are produced in a controlled factory environment, rain, snow, or extreme heat does not affect their creation. Workers can continue making precast concrete panels year-round. By the time they reach the construction site, they are already set and ready to place. This advantage means harsh weather has minimal impact on the building timeline, further reducing unexpected costs or schedule changes. 2.2 Structural Integrity and Durability Engineered for StrengthEach precast concrete wall is carefully designed to support and distribute heavy loads. The internal reinforcements ensure that concrete walls resist bending, cracking, and other structural issues. They can also be tested for load-bearing capacity before reaching the site, offering builders and owners peace of mind. Whether the building is a home or a large-scale facility, these panels uphold strict engineering standards, providing long-term safety and reliability. High-Performance Under Extreme ConditionsPrecast concrete walls exhibit outstanding resilience in areas prone to hurricanes, tornadoes, or seismic events. Their robust composition helps prevent severe structural damage when faced with high winds and debris. Because of this, many architects recommend prefab concrete walls for regions that experience storms or natural disasters. Over the lifetime of a building, this quality can lead to lower repair bills and fewer interruptions in operation. 2.3 Sustainability and Environmental Impact Eco-Friendly ManufacturingModern producers of prefabricated concrete walls often use locally sourced aggregates and efficient production methods. This cuts down on transportation needs and greenhouse gas emissions. In a factory setting, any leftover concrete is often recycled back into new panels, reducing waste. This closed-loop approach supports greener construction practices and aligns with modern sustainability goals. RecyclabilityMaterials used in precast concrete wall panels have a long life cycle. At the end of a structure’s use, the concrete and steel reinforcements can be separated and recycled. Using prefab concrete walls not only conserves resources but also lowers the volume of construction debris sent to landfills. Builders who prioritize sustainable methods appreciate these environmental perks. 2.4 Design Versatility and Aesthetic Flexibility Customization OptionsA variety of finishes, textures, and colors can be applied during the production of wall concrete panels. This allows architects to achieve unique looks that range from polished modern surfaces to more traditional stone-like exteriors. Different form liners and pigments add even more visual appeal. As a result, precast building panels provide flexibility while maintaining structural strength. Integration with Other MaterialsConcrete walls can pair well with glass, metal, wood, or brick. This hybrid style is popular for both modern offices and cozy homes. Architects can also incorporate features like window openings and decorative trim directly into the prefabricated concrete walls. This streamlines the building process, reduces extra on-site work, and preserves design consistency across the entire facade. 2.5 Cost-Effectiveness Reduced Labor CostsBecause precast concrete panels are made off-site, there is less need for extensive formwork, manual pouring, and on-site labor. Fewer workers are required during the installation process, which cuts labor expenses. Over multiple projects, these savings can become substantial, making concrete walling a smart financial choice for large developments and smaller projects alike. Economical Long-Term MaintenanceConcrete wall panels are built to endure. They withstand weathering, corrosion, and daily wear better than many other materials. This results in fewer repairs over time, helping owners save on maintenance costs. By investing in durable prefab concrete walls, property managers can focus resources on upgrades or expansions instead of frequent upkeep or replacements. 3. Types of Precast Concrete Walls 3.1 Solid Wall Solid walls are among the most common forms of precast concrete wall panels. They serve multiple roles in a building’s design and can act as internal partitions or exterior facades. Known for their strength, they deliver effective thermal mass, which helps regulate indoor temperatures. This makes them suitable for parking garages, commercial buildings, and even residential layouts where heat retention or stability is important. 3.2 Insulated Wall Insulated walls include a layer of rigid insulation between two concrete wythes. This design cuts down on heating and cooling costs by maintaining comfortable indoor temperatures. When architects and builders choose these precast concrete panels, they often reduce the number of trades needed because the insulation is already integrated. This streamlines construction, speeds up project timelines, and contributes to an energy-efficient environment. 3.3 Loadbearing Wall Loadbearing walls carry vertical loads from roofs and floors and transfer them to the foundation. They can be made as solid or insulated panels, depending

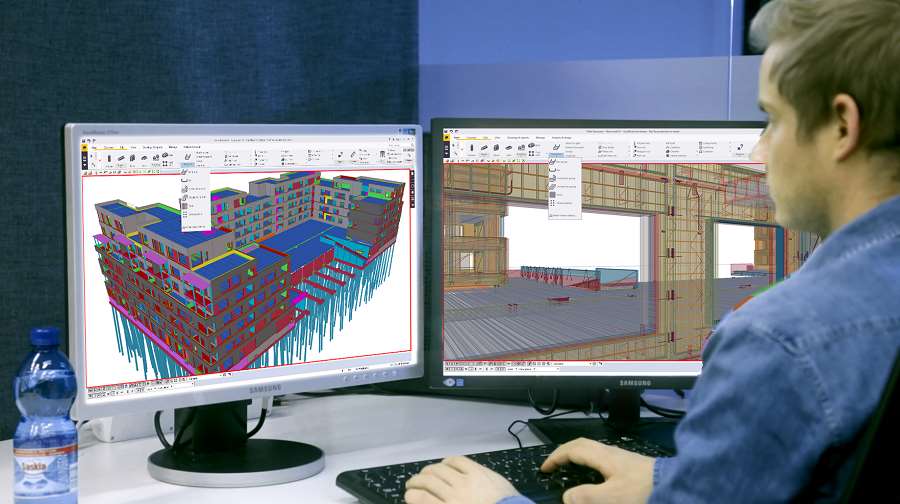

- Detailing constructible link from virtual to the real world!