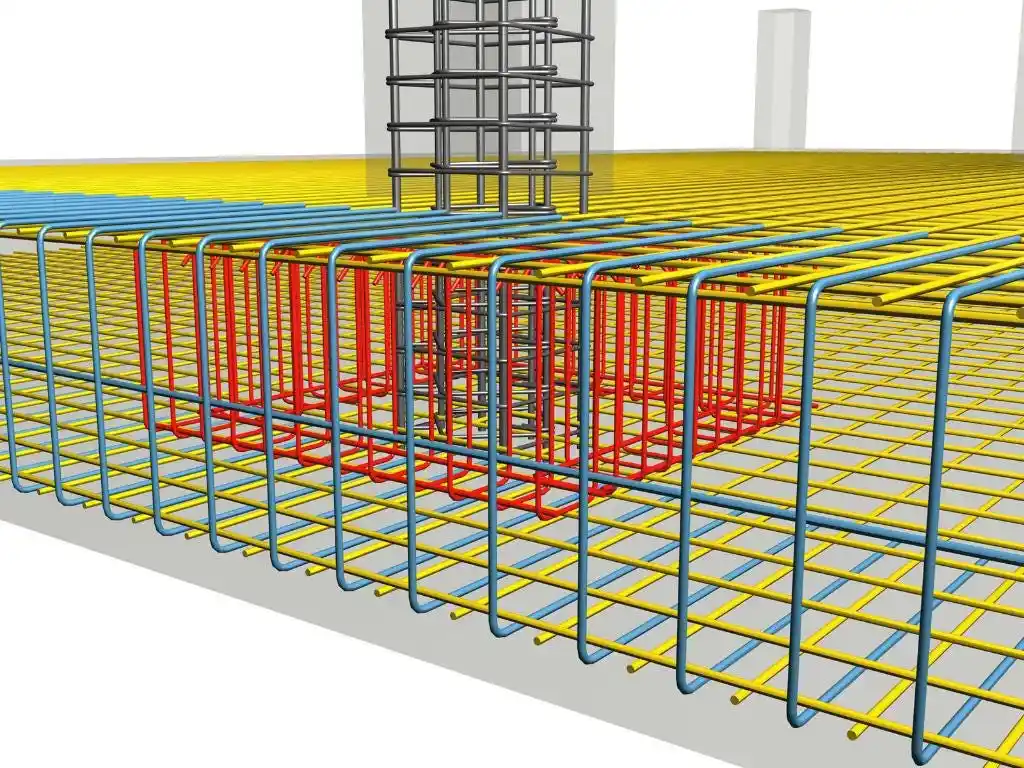

Modern builders rely on accurate plans. In fact, they count on clear drawings for each phase of construction. Structural steel detailing stands at the core of this process. It links the vision of architects to the craftsmanship of builders. Furthermore, it helps create stable frameworks for tall structures. This blog will explore how this discipline transforms the way we design and build today. It will also show why detailing in civil engineering offers huge benefits to all project stakeholders. Strand Co provides many insights into advanced modeling solutions. They focus on precise designs that improve speed and quality in construction. Yet, many people do not realize the true impact of steel detailing. Hence, this blog will dive into key aspects that make it both simple and valuable. Keep reading to learn more about how these techniques shape the world around us. Basics of Structural Steel Detailing Structural steel detailing is the art of creating detailed plans and drawings for steel components. These include beams, columns, and connections. Moreover, these detailed documents guide workers in the fabrication and erection phases. Projects benefit from fewer errors, less waste, and tighter project timelines. Consequently, the entire project team gains more confidence. Why Accuracy Matters In a building site, small mistakes cause big problems later. For instance, if a column is one inch off, it affects beams and roof alignment. Accuracy in detailing for steel construction ensures each piece fits perfectly. As a result, workers save time. They also avoid cutting or re-welding steel on-site. The Impact on Modern Building Projects Structural steel detailing helps teams manage large-scale tasks with ease. In modern building practices, steel forms the backbone of many structures. Designers enjoy freedom to explore unusual shapes. Even so, they must balance safety and functionality. Thus, structural engineering steel detailing ensures each creative idea stands strong against gravity and wind. Evolution of Detailing in Civil Engineering Decades ago, drafters used pencil and paper for steel drawings. That process took a lot of time. Also, it was prone to errors and smudges. But times have changed. With advanced software, detailing in civil engineering has become faster and more accurate. Furthermore, these tools allow real-time collaboration among architects, engineers, and fabricators. The Role of Software Today, professionals use 3D software to visualize each connection. This new approach reveals potential clashes in design. This helps prevent costly changes in the field. In addition, it shortens the time required to finalize drawings. Now, teams can share updates in seconds. Accuracy has improved, and so has on-site efficiency. If you want to explore new methods of structural modelling and detailing, visit the Structural Modelling & Detailing page. You will discover how modern tools refine every phase of a building’s life cycle. Embracing Digital Collaboration Digital platforms encourage more teamwork. For example, structural steel detailers can submit updated models to project managers in an instant. Consequently, the entire group benefits from better version control. They also experience fewer gaps in communication. In fact, many big projects rely on these digital exchanges to meet tight deadlines and budgets. Key Components of Detailing for Steel Construction Detailing for steel construction covers many elements. Each part must suit the overall design. Most projects involve beams, columns, trusses, bolts, and welds. Detailing each of these parts involves a clear set of dimensions, materials, and instructions. In addition, it may include information about coatings, finishes, and fire protection. Primary Steel Elements Each of these parts depends on accurate detailing. Moreover, small oversights can cause bigger delays during assembly. Secondary Steel Components Although they are not the main load-bearing elements, these secondary items remain vital. Therefore, they also need precise dimensions and details. If you want to see how software tools streamline design, check out Revit BIM Modeling and learn about integrated workflows. Tools and Technologies for Tekla Steel Detailing Advanced programs like tekla steel detailing have changed how professionals work. These systems allow 3D modeling, automatic creation of shop drawings, and error checks. In addition, they provide real-time cost estimates. Hence, managers know early if the budget might be exceeded. This tech also reduces manual drafting tasks. Tekla BIM Modeling is a great resource for those seeking more details. This link highlights the use of Tekla in designing complex steel structures. Above all, it shows how software unites architects, engineers, and fabricators in one space. Why Tekla Steel Detailing Is Popular Professionals embrace Tekla because it minimizes rework. The software can quickly detect design conflicts. It also updates all drawings when a model is changed. This saves time and reduces confusion. As a result, even huge projects can maintain smoother workflows. Other Notable Tools You can also learn about Bentley BIM Modeling to see how modern projects handle intricate designs. The Role of a Steel Structural Detailer A steel structural detailer plays a key role from concept to completion. They create the drawings that fabricators use to cut and weld steel. Furthermore, they outline the exact way to piece each section together. Detailers must understand geometry, math, and building codes. Because of this, they often serve as the link between designers and construction crews. Responsibilities of a Steel Structural Detailer: Without the detailer’s effort, projects risk confusion and rework. In many ways, they guide each step of the steel assembly. Efficiency Gains in Structural Engineering Steel Structural engineering steel projects benefit greatly from advanced detailing. It speeds up approvals because everything is clear. Also, it enhances safety. When every connection is precise, the frame can better handle high loads. Moreover, efficient designs can lower the overall steel requirement. This leads to cost savings and less material waste. If you want to see more on how steel frames shape modern buildings, you can read about BIM and Construction. It provides a deeper look at the synergy between BIM tools and on-site work. Environmental Benefits Steel is recyclable. Efficient detailing reduces scrap. Also, steel structures are easy to dismantle or update. This lessens the need for new raw materials. Moreover, refined steel detailing contributes

- Detailing constructible link from virtual to the real world!