Reinforced concrete has long been a cornerstone of modern buildings and infrastructure. It balances the high compressive strength of concrete with the tensile capacity of steel bars. Yet, to achieve the best results, teams need precise plans. That is where rebar shop drawings become essential. These documents detail the shape, size, and placement of steel bars, ensuring each component meets design and safety requirements. In the following sections, we will examine how these drawings are created, why they matter, and how to avoid common errors. This text will also include a summary table of key terms and steps to improve field coordination. By understanding the ins and outs of rebar shop drawings, construction managers, engineers, and detailers can reduce mistakes, save money, and meet strict building codes. Steel reinforcement is often the hidden hero of concrete elements. Without the correct data on how to arrange these bars, there is a higher risk of structural defects and costly rework. Teams need to know bar diameters, bending schedules, splice details, and other factors. If these details are off by even a small margin, site crews might face confusion, and the final product could fail to meet the project’s structural demands. What Are Rebar Shop Drawings Rebar shop drawings are specific documents prepared after reviewing the original structural and architectural plans. They focus on the steel bars that lie within concrete beams, slabs, walls, and columns. Unlike general design sketches, which show the overall building system, these shop drawings offer precise instructions on: Because each bar’s placement can affect the load path and distribution, the accuracy of these plans is vital. Rebar shop drawings are not just for reference; they are the basis on which steel fabricators bend and cut bars. The exactness of these bends, overlaps, and labels simplifies on-site work, reducing the chance of misplacement. These drawings also serve as a communication tool among architects, engineers, project managers, and contractors. By showing how each bar intersects or overlaps, they make conflict detection easier. If the mechanical or electrical trades have pipes or conduits in the same region, the detailer can adjust the layout to avoid clashes. This level of clarity helps keep the project on time and on budget. Purpose of Rebar Shop Drawings The primary goal of rebar shop drawings is to translate broad design concepts into workable instructions. Designers specify the required steel reinforcement, but these specs must be broken down into unique bar elements. Below are key objectives for these technical documents: These factors highlight the true value of rebar shop drawings. Construction teams run fewer risks of missing important rebar details, which can cause expensive field changes or structural issues. Key Elements in Rebar Shop Drawings Each rebar shop drawing must contain crucial data to help field crews place bars correctly. The main elements are: Without these elements, rebar shop drawings lose their usefulness. Each piece of information must be correct and consistent with the project’s general structural plans. Creating Accurate Rebar Shop Drawings When a project involves multiple floors or repeated sections, rebar shop drawings may follow a standard pattern for columns and beams. Detailers can create typical sheets for repeated elements, saving time while maintaining consistency. Common Mistakes with Rebar Shop Drawings Even with advanced software and careful planning, errors still happen. Some frequent issues include: By recognizing these pitfalls, teams can refine their processes. Regular checks, open communication, and quality control help reduce rebar detailing mistakes. Detailed Information Summary Below is a concise summary of the primary items seen in rebar shop drawings and why they matter: Summaries like this help teams recall the critical parts of rebar shop drawings. With so many details, it is easy to miss a key requirement or code reference. Having a quick checklist of terms and objectives allows any professional—whether an engineer, drafter, or site manager to confirm that the documentation meets expected standards. Practical Tips for Rebar Shop Drawings These points go beyond the raw creation of rebar shop drawings, focusing on real-world efficiency. By following them, teams can save time, prevent rework, and produce structures that match the design’s strength criteria. Table: Terms and Descriptions Term Description Bar Mark A unique identifier (like B1 or B2) assigned to each bar group for tracking and installation. Lap Splice The region where two bars overlap to form a continuous tension path in concrete. Bending Schedule A list showing each bar’s shape, angle, and length for easy fabrication and reference. Concrete Cover The distance from the outer concrete surface to the bar, protecting it from corrosion and fire. Hook Angle The bend at the bar’s end used for anchorage or to increase bond with concrete. Shape Code A standard reference to a particular geometry, helping detailers and fabricators maintain consistency. This table offers a quick look at vital terms that appear in rebar shop drawings. Each term represents a key aspect of steel reinforcement and needs to be checked thoroughly before finalizing any documentation. Field Coordination for Rebar Shop Drawings On-site work can be hectic, with different crews operating under tight deadlines. Field coordination for these drawings ensures the structural, architectural, and MEP teams cooperate: Through proper coordination, rebar shop drawings remain a reliable reference rather than a set of outdated plans on a project site. The best drawings lose their value if no one in the field applies them correctly. Conclusion Reinforced concrete relies on correct steel placement, making rebar shop drawings the backbone of a successful project. They ensure that the right bars go to the right places and meet the engineer’s design intent. By including bar schedules, splice details, bending instructions, and clear labeling, these documents simplify the work of fabricators and installers. When done well, they minimize errors, keep project budgets under control, and maintain high safety standards. In a busy construction environment, rebar shop drawings bridge the gap between design theory and hands-on practice. A thorough review of each drawing, along with active communication among all trades, leads to smooth installations. Adding in

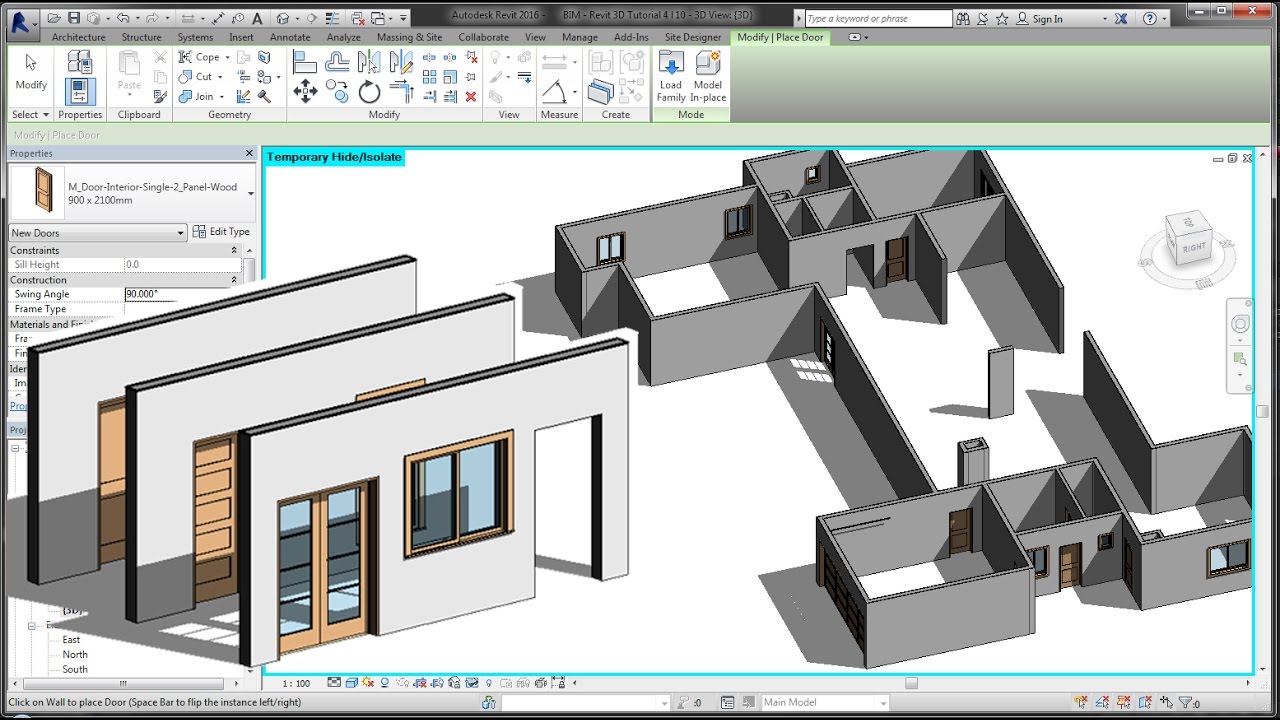

- Detailing constructible link from virtual to the real world!