In construction projects, structural steel detailing is very critical to success. As a mediator between the engineering design and the fabrication, it is the means of transformation of structural intent into the exact shop drawings and models. Although precision has always been the main objective, cost-effectiveness in steel detailing processes has gained more significance with the constraints in construction budgets and shortening of construction schedules.

A small ineffectiveness in the detailing process, like rework, lack of coordination, or late revision, may cause serious cost overruns in the process of fabrication and erection. The blog discloses the real-life effective strategies of cost reduction in structural steel detailing processes, based on smarter planning, technology integration, coordination plans, and optimization of processes.

Why Structural Steel Detailing Costs Matter

Details of structural steel have implications for several downstream operations, such as the purchase of materials, the fabrication process, transport, and assembly. Mistakes or inefficiency at the level of detailing may result in:

- Fabrication delays

- Material waste

- Costly RFIs and change orders

- Site rework and erection conflicts

As steel detailing lies at the border of design and construction, its enhancement also impacts the rest of the project lifecycle. Cost savings in this case are normally much more significant than savings that are realized in the later stage of construction.

Start with Clear and Coordinated Design Inputs

One of the most common cost drivers in steel detailing is incomplete or poorly coordinated design information. Ambiguous drawings, missing details, or late design changes force detailers to revise models repeatedly.

Cost-Saving Strategy

Ensure that structural engineers provide:

- Clearly defined load paths

- Consistent member sizing

- Finalized connection design responsibility (EOR vs fabricator)

Early coordination between structural, architectural, and MEP teams helps eliminate conflicts before detailing begins. Investing time upfront reduces costly revisions later.

Standardize Steel Detailing Practices

Absence of standardization causes variation in the level of detailing output, inefficiency, and redundant complexity. Every custom detail increases fabrication time and cost.

How BIM Reduces Costs

- Early identification of clashes will eliminate rework.

- Proper quantities minimize wastage of material.

- There is better coordination through the use of 3D visualization.

- Computer aided drawing saves man hours.

Avoid over-modeling. Unnecessary detailing may make modeling of unnecessary parts or over-detailed parts because the additional detailing is not beneficial. Target BIM at the factors that have a direct influence on fabrication and erection.Bolt size and type of weld.

Standardization makes it easier to describe, makes it quicker to make, and minimizes errors. Fabricators obtain repeatable processes and erectors obtain familiarity, which saves cost of labor at the sites.

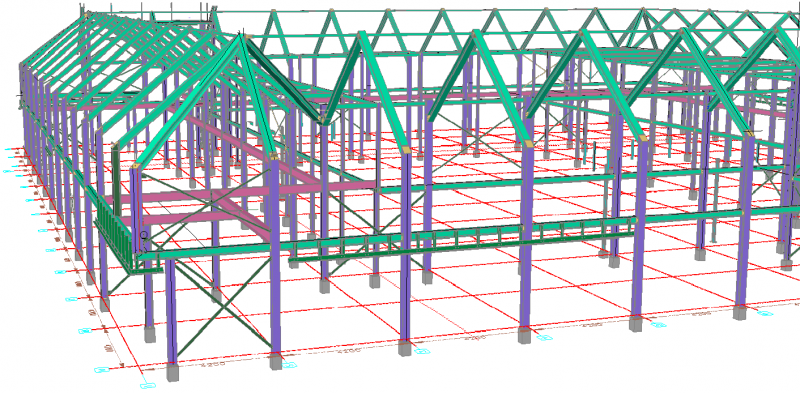

Leverage BIM and 3D Modeling Effectively

The building information modeling (BIM) has revolutionized structural steel detailing; however, it has cost advantages.

Lack of clarity in regards to Level of Detail (LOD) is a key contributor to wasted effort. Excessive details make them expensive but the opposite is not true since excessive under-details cause fabrication mistakes.

Cost-Saving Strategy

Define LOD requirements clearly at project kickoff:

- LOD 300 for coordination

- LOD 400 for fabrication

- LOD 500 only when required for asset management

Aligning LOD expectations between owners, engineers, and fabricators prevents redundant modeling and unnecessary revisions.

Improve Early Collaboration with Fabricators

Fabricators have hands-on information which can have a big effect on cost effectiveness. Without their input in the details, it is possible that a design is technically accurate but too costly to create.

Cost-Saving Strategy

Involve fabricators early to:

- Optimize member sizes

- Simplify connection details

- Reduce complex welds

- Improve shop efficiency

Fabricator-driven value engineering at the detailing stage often results in material savings, faster production, and fewer shop issues.

Optimize Connection Design

One of the most expensive and laborious features of structural steel fabrication is connections. Unnecessarily complicated or designed connections add to the cost of materials, labor, and inspection.

Cost-Saving Tips

- Use standardized connection families

- Avoid unnecessary full-penetration welds

- Minimize unique bolt sizes

- Prefer bolted connections where feasible

Connection designs that are simple and repetitive save detailing time and save a lot of cost associated with fabrication.

Reduce Rework Through Clash Detection

One of the largest unseen expenses in the process of steel detailing is rework. Conflicts between steel, MEP systems and architectural items are usually revealed too late.

Cost-Saving Strategy

Conduct structured clash detection sessions:

- Before issuing shop drawings

- After major design changes

- Prior to fabrication release

Resolving clashes digitally costs far less than fixing them on-site. Proactive coordination directly translates into cost and schedule savings.

Implement a Clear RFI Management Process

RFIs are inescapable in the structural steel detailing, however uncontrolled RFIs soon become the greatest source of inefficiency. Delaying clarifications by detailers leads to low productivity, delayed schedules, and revisions. An obvious RFI management process records the questions, prioritizes them, and closes them without interfering with the working process.

Cost-Saving Strategy

- Establish RFI response timelines

- Prioritize detailing-related RFIs

- Track recurring issues to prevent repetition

A structured RFI workflow keeps detailers productive and reduces downstream delays.

Train and Upskill Steel Detailers

Project cost and accuracy depends on the level of skill of steel detailers. Novice detailers tend to have to be revised more frequently, come up with vague drawings and fail to notice fabrication or erection restrictions. Such problems are carried over to the rework, delays and extra coordination costs.

Cost-Saving Strategy

Invest in:

- Software training (Tekla, SDS2, Advance Steel)

- Connection detailing best practices

- Fabrication and erection awareness

Well-trained detailers reduce coordination issues and produce constructible drawings, saving time and money across the project.

Use Automation and Smart Detailing Tools

Manual detailing tasks consume valuable time and increase the likelihood of errors. Modern steel detailing software offers automation features that streamline repetitive work and improve consistency across models and drawings.

Automation Benefits

- Auto-connection tools reduce repetitive tasks

- Rule-based modeling ensures consistency

- Automated drawing updates save revision time

Cost-Saving Tip

Another way is through custom macros and templates that have been designed to conform to fabricator standards, which are more efficient. Automation directly reduces the cost of labor and project delivery time by minimizing manual work and re-work.

Limit Late Design Changes

One of the costliest disruptive steel detailing processes is late-stage design modifications. Even the slightest revisions may cause ripple effects through models, shop drawings, quantities of materials, and fabrication schedules.

Cost-Saving Strategy

- Freeze design milestones

- Enforce formal change management

- Quantify cost impacts before approving changes

Late-stage design changes are one of the most expensive disruptions in steel detailing workflows. Even minor revisions can trigger cascading changes across models, shop drawings, material quantities, and fabrication schedules.

Improve Communication Between Teams

Improved communication starts with regular coordination meetings, shared digital platforms, and clear documentation of decisions. When changes, clarifications, or updates are communicated promptly, detailers can adjust models without rework. Transparent collaboration reduces RFIs, avoids fabrication conflicts, and keeps all stakeholders aligned. Effective communication ultimately saves time, prevents disputes, and improves overall project efficiency.

Cost-Saving Strategy

- Hold regular coordination meetings

- Use shared collaboration platforms

- Document decisions clearly

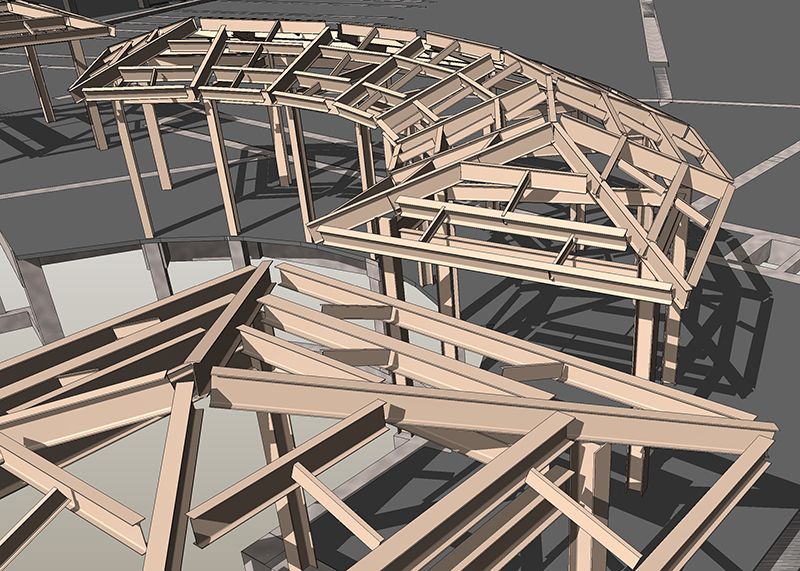

Align Detailing with Fabrication Workflow

Detailing that ignores fabrication workflow often results in inefficient shop processes and increased labor costs. Even accurate models can become problematic if they do not reflect real shop capabilities or production methods.

Cost-Saving Strategy

Detail with fabrication in mind:

- Match shop equipment limitations

- Optimize piece sizes for handling

- Reduce complex geometries

Detailing that aligns with shop workflow improves productivity and lowers fabrication costs.

Optimize Material Usage and Nesting

Detailing that ignores fabrication workflow often results in inefficient shop processes and increased labor costs. Even accurate models can become problematic if they do not reflect real shop capabilities or production methods.

Cost-Saving Strategy

- Coordinate detailing with CNC nesting software

- Standardize member lengths

- Reduce unnecessary camber and special profiles

Optimized material usage results in significant cost savings, especially on large-scale steel projects.

Conduct Regular Quality Checks

Effective QA/QC processes include internal model audits, connection reviews, and drawing cross-checks. Verifying bolt sizes, weld types, and member geometry ensures consistency and constructability. Regular quality checks reduce RFIs, minimize rework, and improve confidence in released shop drawings. Investing time in quality control protects budgets and improves project reliability.

Cost-Saving Strategy

Implement internal QA/QC checks:

- Model audits

- Drawing reviews

- Connection validation

Measure and Improve Workflow Performance

Without performance measurement, inefficiencies in steel detailing workflows remain hidden. Tracking productivity and quality metrics allows teams to identify problem areas and implement targeted improvements.

Cost-Saving Strategy

Track key metrics:

- Hours per ton

- Revision frequency

- RFI response times

- Rework percentage

Using performance data allows teams to refine workflows and continuously reduce costs.

Conclusion

Cost savings in structural steel detailing workflows don’t come from cutting corners. Instead, they come from smarter processes, strong coordination, and the right use of technology—especially for projects across Hauppauge and the greater New York area. From early design alignment and BIM coordination to standardized detailing and close fabricator collaboration, every improvement adds real value throughout fabrication and construction.

Local firms like STRAND Consulting understand how New York construction timelines, codes, and site conditions impact steel detailing decisions. By focusing on efficiency, clarity, and constructability, structural steel detailing teams can reduce rework, limit material waste, and speed up project delivery for commercial and industrial builds across Long Island.

In today’s competitive construction market, optimizing steel detailing workflows is more than a cost-saving step—it’s a strategic advantage. When done right, structural steel detailing becomes a key driver of project success, delivering safer, faster, and more cost-effective outcomes for local builders and developers.