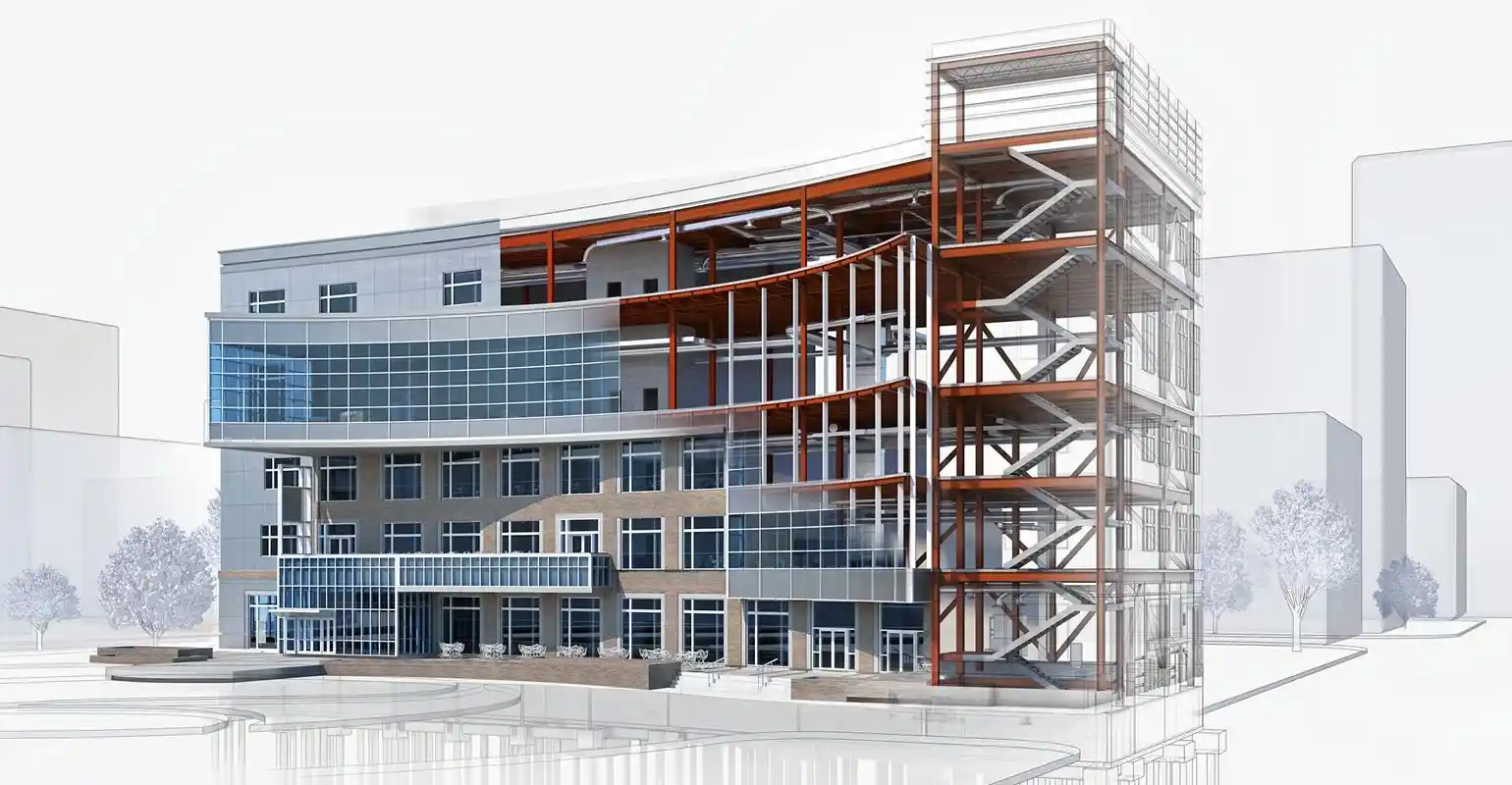

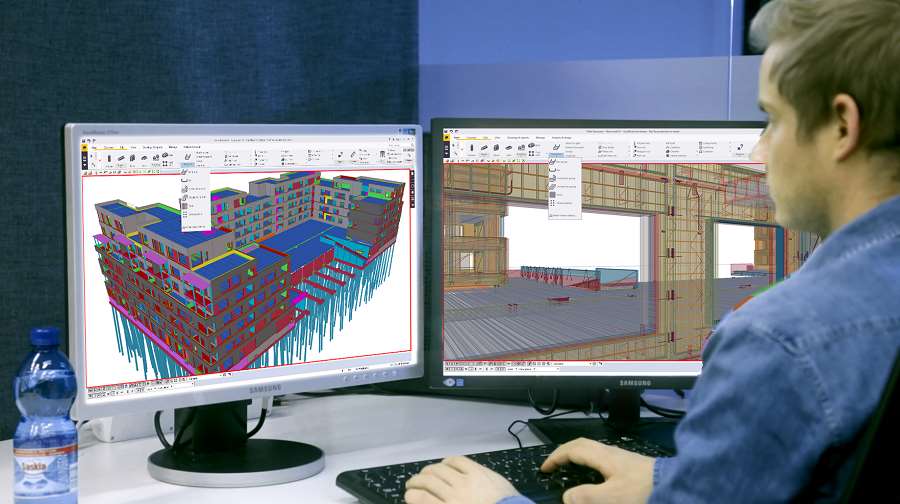

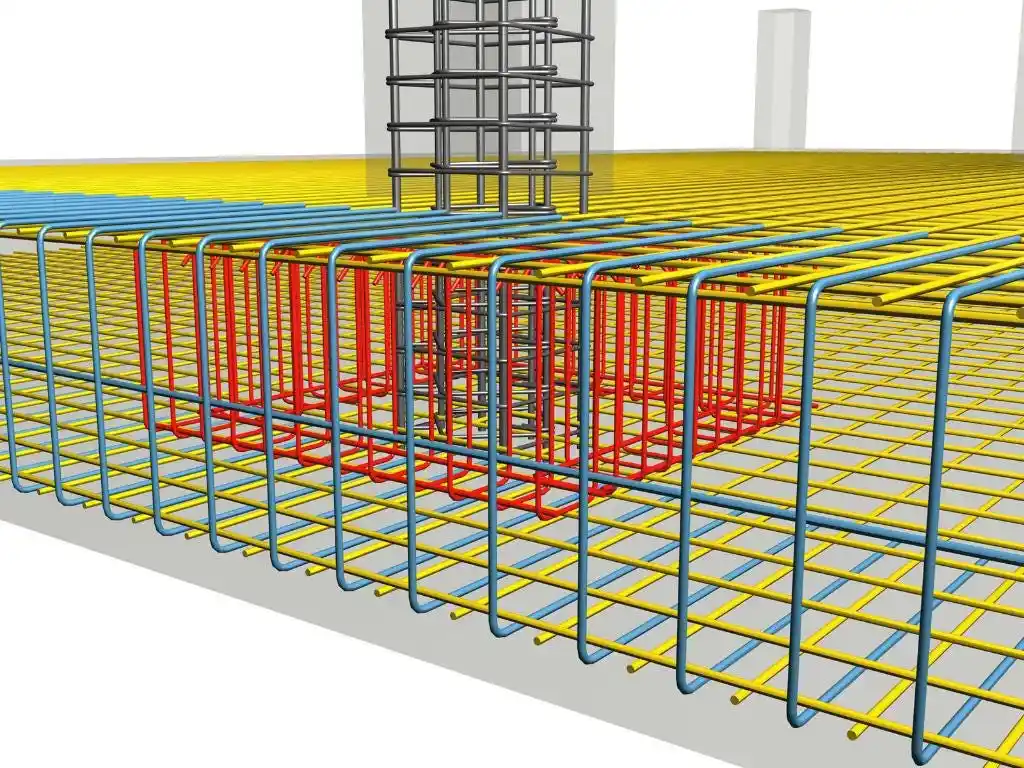

Have you ever wondered why modern buildings seem more precise and efficient than older structures? You are not alone. Many people get curious about the differences between traditional design methods and the cutting-edge approach known as building info modeling. In my experience, old-fashioned paper plans often led to confusion in the field. However, new modeling methods reduce guesswork and speed up the building process. In fact, the entire construction field has changed in exciting ways. Rebar detailing and BIM techniques, for example, have shifted how experts handle complex structural components. Furthermore, owners now demand a more coordinated system that saves both time and money. Meanwhile, 3D rebar detailing is reshaping construction by reducing human error and improving teamwork. Also, many specialists have noticed the shift away from older design software. This new wave of technology is capturing attention because it allows easy collaboration. Shifting from Traditional Design to BIM People often ask, “What does BIM stand for?” It stands for Building Information Modeling. Yet, there is more to this technology than just a name. Besides creating 3D images, it houses data about materials, schedules, and maintenance details. But some folks still cling to classic blueprint drawings, which can cause slowdowns and costly mistakes. In contrast, advantages of BIM tools keep everyone informed. By comparison, old methods lacked a central database of project details. On the other hand, modern solutions integrate data and geometry in one place. Meanwhile, 3D modeling is more than a fancy buzzword. It is a serious improvement over plain paper drawings. Also, there are times when people worry that these new tools might be too costly. However, the long-term savings and smoother communication often outweigh the initial expense. Moreover, some big gains come from better clash detection, reduced rework, and clearer team roles. Embracing New Tools and Workflow In many modern projects, the term bimkit pops up among experts and designers. In essence, it is a set of tools or services that streamline workflow. This resource can guide you through what is BIM software and how to use it. If you wish to take the next step, you might consider specialized modeling services. These options often include detailed planning, accurate 3D models, and advanced data integration. In fact, many professionals rely on these solutions to handle large, complicated structures. Furthermore, they see fewer onsite surprises, leading to more predictable results. Yet, a question arises: Should you keep relying on older approaches? Or is it time to embrace new processes for your next project? By the end of this discussion, you should have a solid grasp on the core differences. The Basics of Traditional Design Traditional design has been around for centuries. Builders drew plans by hand or used basic computer-aided drafting (CAD). They would outline walls, beams, doors, and windows. Yet, this system involves separate sheets of information. Consequently, architects, engineers, and contractors might see conflicting details. Often, they had to cross-check each sheet. This process caused delays and extra costs when errors popped up. Moreover, older methods relied heavily on manual calculations. If someone made a small mistake, it might go undetected for weeks. Eventually, teams found problems in the middle of construction. That meant tearing out work and starting over. Obviously, wasted materials and time harmed budgets. Overall, traditional design has a linear workflow. One group finishes a task before passing it along to the next group. This siloed approach can slow progress and create confusion. Why Did We Stick with It for So Long? Many architects grew up with paper blueprints. They knew how to read them fast. Plus, legacy projects were stored on paper. Changing to digital tools required new hardware, licenses, and training. That seemed daunting. In addition, some people felt comfortable with the old ways. They believed technology might complicate tasks. Consequently, traditional design remained the norm for decades. Yet, the need for more integrated methods became obvious over time. What Is BIM Modeling? What is BIM modeling, exactly? It is a digital approach that incorporates data into a 3D model of a building. Each element, from walls to pipes, has detailed information. Experts can see how these elements interact before the first shovel hits the ground. Essentially, building info modeling acts as a living database. Architects, engineers, and contractors can update it in real time. Then, everyone has access to the same version. Hence, confusion drops, and collaboration improves. This approach moves us away from flat 2D drawings. With 3D visualization, teams spot design clashes early. They can fix issues in the virtual model, not on the site. Moreover, the system calculates material quantities and schedules tasks. That saves guesswork. In addition, you can plan cost, scope, and labor from the start. This integrated nature leads to stronger efficiency. When the plan changes, the model updates instantly. Key Elements of Building Information Modeling Benefits of BIM That Traditional Design Lacks Benefits of BIM often outshine those of traditional methods. First, it enables accurate cost estimates because the model knows the exact amount of resources needed. Second, it reduces rework through efficient clash detection. Third, it strengthens team communication by keeping all stakeholders on the same page. These outcomes push more companies to learn and adopt this technology. In addition, there are benefits of building information modeling for owners and investors. They see fewer delays and budget overruns. They also have a clearer picture of the final product. The data remains useful long after the building is complete. It can show future renovations or expansions. In short, the model is a long-term asset. When a new tenant moves in, the facilities team can find mechanical system details quickly. This knowledge makes building operations run smoother. Advantages of BIM for Different Professionals Architects For architects, advantages of BIM include swift design changes. The model updates in real time. No need to redraw every sheet when a door moves a few feet. Also, architects can walk through a 3D visualization. This helps them catch potential layout problems early. Engineers Engineers value data-driven

- Detailing constructible link from virtual to the real world!