The need of accuracy in the steel detailing has never been stronger as the construction projects are getting more sophisticated, with shorter delivery schedules. By 2026, steel structures will be designed, described, manufactured, and installed with almost no error tolerance. This is where the Tekla Structures still holds a lead in the industry as the most reliable solution to precise steel detailing.

Tekla Structures is used in the construction of high-rise buildings, industrial plants, infrastructure and heavy steel construction, with the ability to work with a single constructible model, which is a mirror of the real world. Overall, this blog discusses how Tekla structures can provide unsurpassed accuracy in steel detailing in the year 2026 and why it will continue to be indispensable to the current structure processes.

The Growing Need for Precision in Steel Detailing

Steel detailing errors are costly. A misplaced connection, incorrect bolt specification, or misaligned member can result in fabrication delays, material waste, rework, and site disputes. In today’s environment of prefabrication, modular construction, and lean project delivery, even small inaccuracies can ripple into major cost overruns.

In 2026, steel detailing is no longer just about producing shop drawings. It is about creating fabrication-ready digital models that integrate seamlessly with downstream processes such as CNC machining, automated fabrication, logistics planning, and erection sequencing. Tekla Structures is uniquely positioned to meet these demands by enabling model-based detailing with a high level of reliability and constructability.

What Makes Tekla Structures a Steel Detailing Leader

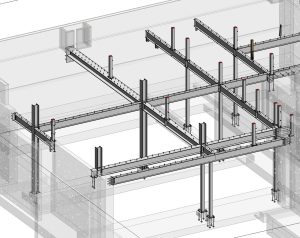

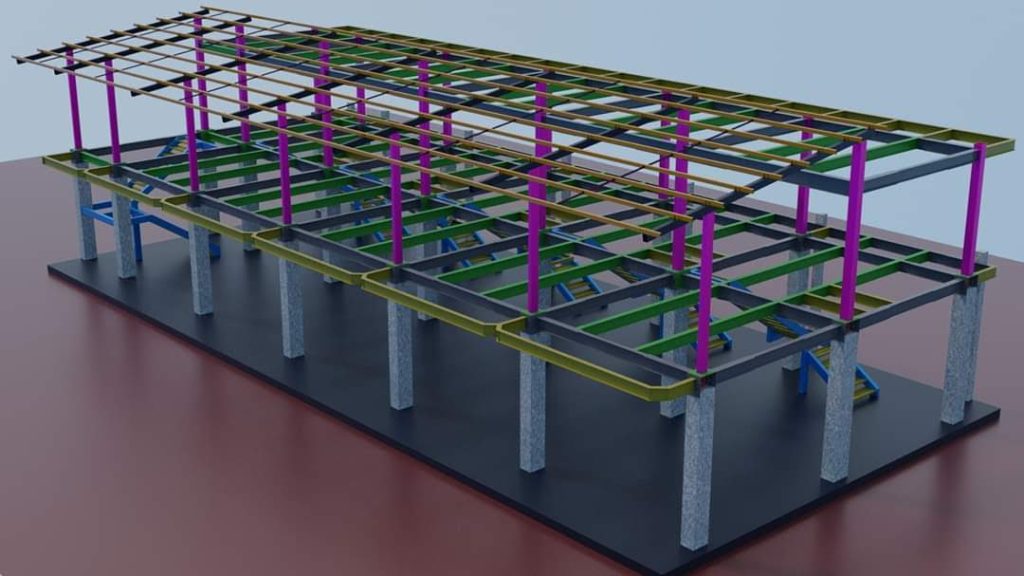

Tekla Structures is a building information modeling (BIM) software that is created with structural engineering and detailing in mind. Tekla is constructed based on the reality of steel fabrication and construction, unlike generic modeling tools.

Its main advantage is that it can model in great detail with data rich 3D models that are an exact representation of all the bolts, welds, plates, and connections that will be constructed. This makes the model not only look right, but it can be built.

Tekla is still in an upgradation process in 2026 employing better automation, interoperability and cloud collaboration, making it a necessity in any steel-intensive construction.

Model-Driven Steel Detailing Accuracy

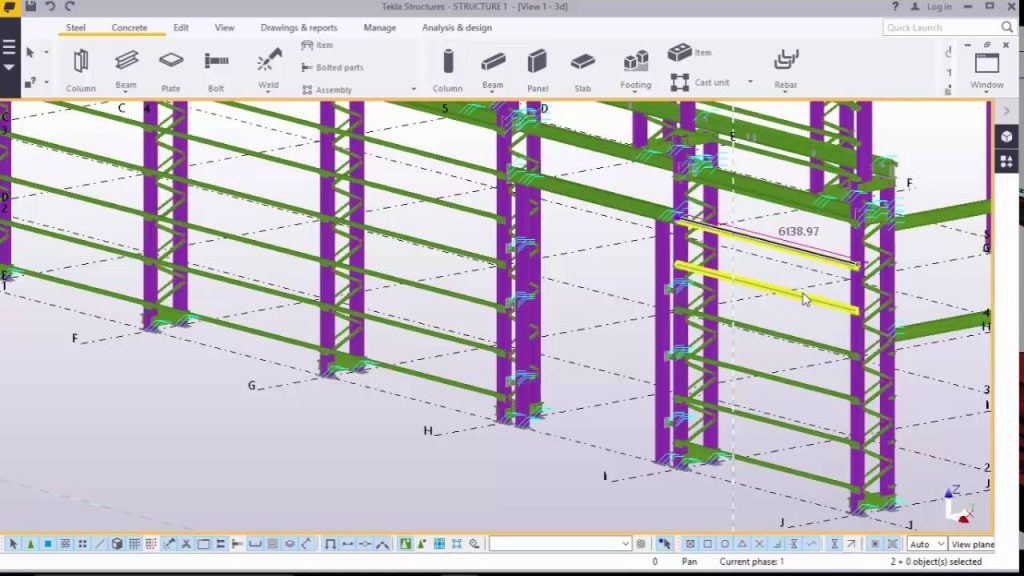

At the heart of Tekla Structures is its model-driven approach. Every drawing, report, and fabrication output is generated directly from the 3D model. This eliminates the inconsistencies that often occur when drawings are manually updated or produced separately from the design model.

When a change is made to a beam size, connection type, or plate thickness, Tekla automatically updates:

- Shop drawings

- Assembly drawings

- Material takeoffs

- Bolt and weld lists

This dynamic relationship between model and documentation significantly reduces human error and ensures that all stakeholders are working from the latest information.

Advanced Connection Modeling for Real-World Conditions

Connections are one of the most critical and error-prone aspects of steel detailing. Tekla Structures offers an extensive library of parametric connection components that reflect real-world fabrication and erection practices.

Detailers can model:

- Moment and shear connections

- Braced frame connections

- Custom plate and weld configurations

- Complex node conditions

In 2026, Tekla’s connection tools are more intelligent than ever, allowing automated adjustments based on member geometry, load requirements, and design standards. This ensures consistency across the project while still allowing customization where needed.

Supporting Fabrication-Level Detail (LOD 400 & 500)

Tekla Structures excels at producing models at LOD 400 and LOD 500, which are essential for accurate fabrication and as-built documentation. At these levels, every element is defined with exact geometry, tolerances, and specifications.

This level of detail allows fabricators to confidently use Tekla models for:

- CNC machine inputs

- Automated cutting and drilling

- Robotic welding

- Prefabrication and modular assembly

By eliminating ambiguity, Tekla Structures minimizes shop-floor interpretation and reduces costly mistakes during production.

Seamless Integration with Fabrication and CNC Systems

One of Tekla’s strongest advantages in 2026 is its seamless integration with fabrication workflows. Tekla supports industry-standard formats that connect directly to CNC machines and fabrication management systems.

Fabricators can extract:

- NC files

- DSTV files

- Material reports

- Assembly sequences

This digital continuity ensures that what is detailed in the model is exactly what gets fabricated, significantly improving accuracy and productivity.

Clash-Free Coordination with Other Disciplines

Steel structures do not exist in isolation. They must coordinate with architectural elements, MEP systems, and civil components. Tekla Structures supports robust model coordination and clash detection, ensuring steel elements fit perfectly within the overall building context.

By federating Tekla models with models from Revit, IFC-based platforms, and other BIM tools, teams can identify spatial conflicts early. This reduces site clashes, redesigns, and last-minute field fixes that compromise accuracy and schedules.

Automation and Smart Detailing in 2026

Automation plays a growing role in steel detailing efficiency. In 2026, Tekla Structures offers enhanced tools for:

- Automated drawing creation

- Rule-based connection assignment

- Intelligent numbering and sequencing

- Template-driven reporting

Detailers can focus on engineering judgment and quality control rather than repetitive manual tasks. This not only improves speed but also enhances consistency and reduces the risk of oversight.

Managing Complex Steel Projects with Confidence

Large-scale steel projects often involve thousands of members, multiple fabricators, and tight coordination requirements. Tekla Structures handles this complexity with ease through:

- Model-based project organization

- Phased detailing workflows

- Multi-user collaboration

In 2026, cloud-enabled collaboration allows geographically distributed teams to work on the same model with clear version control and change tracking. This ensures accuracy is maintained even as projects scale in size and complexity.

Accurate Steel Quantity Takeoffs and Cost Control

Accurate steel detailing directly impacts cost estimation and procurement. Tekla Structures provides precise quantity takeoffs based on the actual model geometry and specifications.

Project teams can generate:

- Weight calculations

- Bolt and weld quantities

- Coating and surface area reports

This accuracy improves procurement planning, reduces material waste, and supports more reliable cost forecasting throughout the project lifecycle.

Supporting Erection Planning and Sequencing

Steel accuracy does not stop at fabrication, it extends to erection. Tekla Structures supports erection planning by allowing teams to model installation sequences, temporary supports, and lifting considerations.

Erection drawings and sequences generated from Tekla models help site teams:

- Reduce installation errors

- Improve safety planning

- Optimize crane usage

This level of planning ensures that steel components arrive on site ready to be installed without modification.

Compliance with Global Standards and Codes

In 2026, steel projects often span multiple regions and must comply with various international standards. Tekla Structures supports a wide range of codes and standards, enabling consistent detailing across global projects.

This flexibility allows firms to maintain accuracy while meeting regulatory and client-specific requirements.

Why Tekla Structures Remains Essential in 2026

Despite rapid technological advancements, Tekla Structures remains the gold standard for steel detailing because it is built around constructability, accuracy, and real-world workflows. Its focus on fabrication-level modeling, combined with automation and interoperability, makes it indispensable for modern steel construction.

As projects continue to demand faster delivery, tighter budgets, and higher quality, the role of Tekla Structures in ensuring accurate steel detailing will only grow stronger.

Conclusion

In 2026, accurate steel detailing is no longer optional for projects in New York—it is a true competitive advantage. At Long Island and across the tri-state area, steel projects demand precision, speed, and reliability. That is why STRAND Consulting relies on Tekla Structures to deliver results that meet local construction standards with confidence.

By bringing design, detailing, fabrication, and erection into one trusted model, Tekla Structures removes guesswork and keeps steel workflows clear and efficient. From concept to construction, it helps ensure every connection, bolt, and beam aligns with real-world site conditions.

Located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, STRAND Consulting supports fabricators, engineers, and contractors with data-driven steel solutions built for accuracy and performance. For organizations that value precision in steel construction, Tekla Structures continues to be the preferred tool for turning models into reality.