- Detailing constructible link from virtual to the real world!

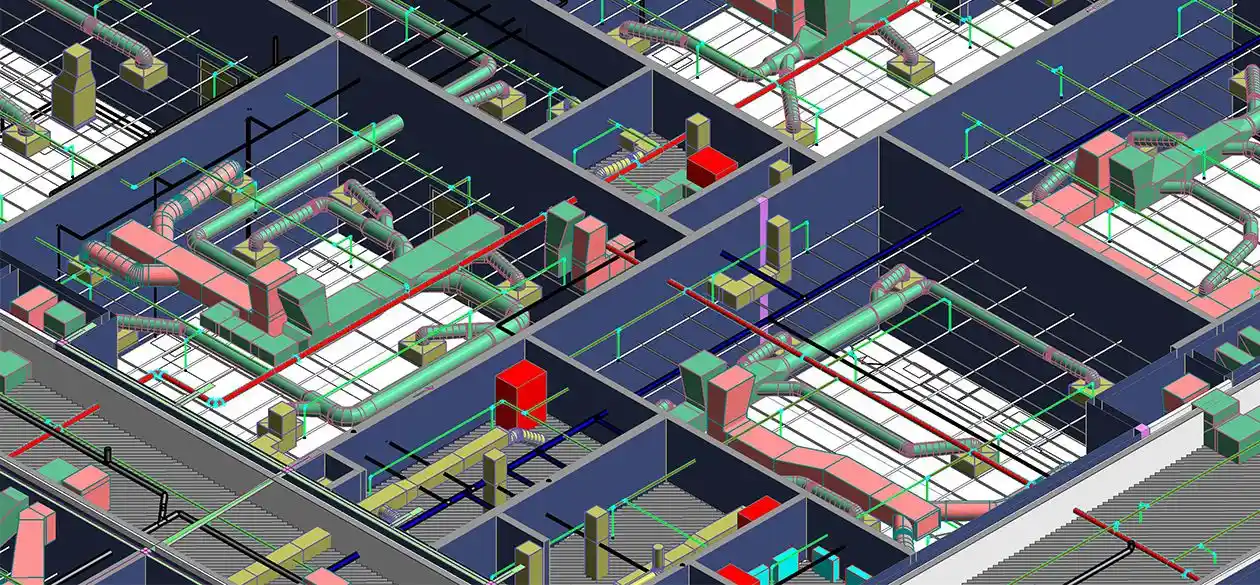

MEP coordination refers to the conjunction of mechanical, electrical, plumbing, and fire protection systems to detect and solve conflicts in the pattern of a single building model. Our professionals at Strand Co. implement advanced clash detections, careful spatial planning, and smooth (real-time) cooperation to ensure that your systems interact well and in optimal efficiency.

The preemptive integration we apply at the first stages of architecture and building design eliminates the possibility of system clashes and spatial issues occurrences such that we encounter minimal construction delays.

At Strand Co., we provide complete MEP coordination solutions that detect clashes, assist in construction, and guarantee mechanical, electrical, and plumbing systems unified integration. We move past the confines of conventional modeling approaches by providing coordinated solutions that are tailored for each construction phase for you.

With Navisworks and Rivets we see the future trouble with HVAC, plumbing, electrical, and structures before it gets serious. The refined detail relating to group clash analysis and documentation and resolution is included in coordination meetings which will see to it that your project does not fall out of schedule.

Our federated BIM models gather all trade smarts for best installation fit. With an application of these models, one-site work becomes more effective, and interpersonal relationships between different parties are much better improved.

We provide coordinated shop drawings and spool drawings that meet contractor and manufacturer specifications—ready for immediate use during fabrication and construction.

We work closely with architects to integrate MEP systems without compromising design aesthetics or space utilization. Our team considers ceiling heights, shaft placement, and wall locations to maintain architectural intent while ensuring technical accuracy.

Our skills in the early building design phase are spatial planning, constructability assessment and value engineering support.

In order to guarantee efficient construction and long term operational benefits, Strand Co values MEP coordination alignment at an early building design stage. Collaborating with mechanical, electric, and plumbing systems from the architectural and prostruction cycles is important for us because it allows us to avoid design clashes, avoid costly changes, and simplify the project process.

Such an approach leads to a decreased number of lure complications on-site, a smoother construction timeline while ensuring that the finished space continues to boast high performance over time.

Our collaboration extends across disciplines:

With years of experience in engineering construction design, we know that coordinated systems are the backbone of efficient building structure execution. Our team combines BIM expertise, domain knowledge, and proactive communication to deliver unmatched service every time.

Whether you’re working on a new facility or retrofitting an existing structure, Strand Co’s MEP coordination services ensure your systems work together seamlessly. Avoid rework, save money, and deliver faster with our precision-driven approach. Partner with Strand Co for expertly delivered MEP BIM services that minimize risk, reduce cost, and drive construction efficiency. Whether you’re at the concept stage or deep into coordination, our team is ready to support your vision with detail-rich MEP drawings, coordinated MEP BIM models, and dedicated project support. Schedule a free consultation today and discover how our expertise in BIM and MEP can elevate your next build.

Foster real-time coordination among architects, engineers, and contractors for unified workflows.

Identify and resolve design conflicts early to avoid delays, rework, and budget overruns.

Deliver clear, detailed MEP plans for swift permit approvals and stakeholder sign-off.

Plan systems efficiently to maximize space use and streamline on-site installations.

Discover our full range of digital solutions, from advanced CAD tools to comprehensive project management services, tailored to optimize your infrastructure projects.

MEP stands for Mechanical, Electrical, and Plumbing—three essential systems in a building that ensure functionality and comfort.

In construction, MEP refers to the integrated design and installation of mechanical, electrical, and plumbing systems to support building operations.

A MEP coordinator oversees the planning, coordination, and integration of MEP systems in construction projects, ensuring they align with architectural and structural plans.

MEP stands for Mechanical, Electrical, and Plumbing—the core technical disciplines involved in building services engineering.

MEP systems manage heating, cooling, lighting, power distribution, water supply, and waste management, making buildings safe and livable.

In maintenance, MEP refers to the ongoing inspection, repair, and optimization of a building’s mechanical, electrical, and plumbing systems to ensure efficiency and reliability.

When we streamline our method from preliminary review stages through clashes resolution stages, we get smoother execution of projects, reduced rework and increased construction quality.

Our first step will require a discussion with engineers, architects, contractors and consultants to learn more about your goals, project specifications, and critical timeline metrics. It enables us to define the limits of our MEP coordination services, understand how the systems interface with one another, and identify those parts of the project that require special attention.

We assemble and analyze all essential input materials including the architectural draw, the structural draw, the concept drawing, and MEP marking information. Upon careful review of all input documents, we determine a comprehensive strategy for coordinated modeling and clash resolution.

Using high-quality software, such as Revit and Navisworks, we make precise 3D models of the HVAC, plumbing and electrics installation. Through our BIM-based modeling, we can visualize each system layout in regard to the building and identify conflicting areas.

Using sophisticated clash detection routines, we detect and fix clashing between MEP installations and adjacent architectural/structural elements. We record all clashes, engage the appropriate team in discussion, and collaborate to eliminate clashes prior to arrival at the site.

A selection of stakeholders from your design and construction groups meets from time to time to review the models, resolve the existing disagreements, and make the necessary changes to the design if needed. This ensures that all parties are always tuned in and cooperation happens in real time as the coordination moves forward.

After clash elimination and completion of full system coordination, we offer all needed MEP drawings for construction purposes, including duct installations, electrical conduit routes, piping arrangements, and equipment layouts.

Our professionals can help after the coordinated drawings are sent upon production. During the construction phase, Strand Co implements needed corrections to drawings, stays up-to-date with changes to the project, and checks whether outcomes of the build are in agreement with the design concept.

We rely on industry-leading software to deliver accuracy and efficiency: