As part of construction design today, blueprints known as MEP plans help integrate the mechanical, electrical, and plumbing systems throughout the building. Without these systems, any building would lack climate control, proper lighting, electricity, water, drainage, waste disposal, and fire protection. If engineers and contractors coordinate these systems from the start, a building can function well, safely, and in a sustainable manner.

A beautiful architectural plan could become very difficult to carry out without reliable MEP plans. Preventing costly changes in construction is possible through avoiding clashes and inefficiency in systems with these plans.

The Importance of MEP Plans in Building Construction Projects

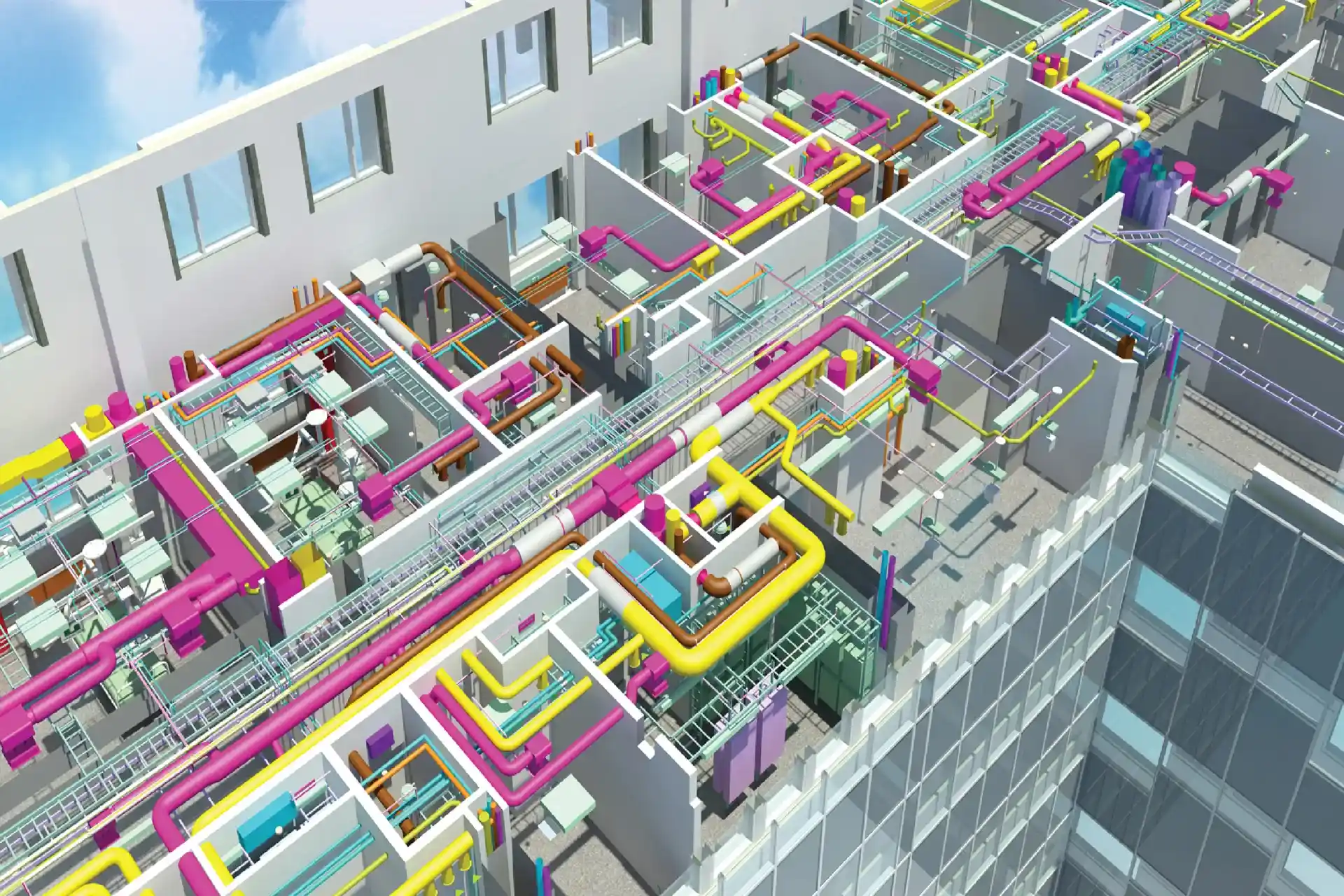

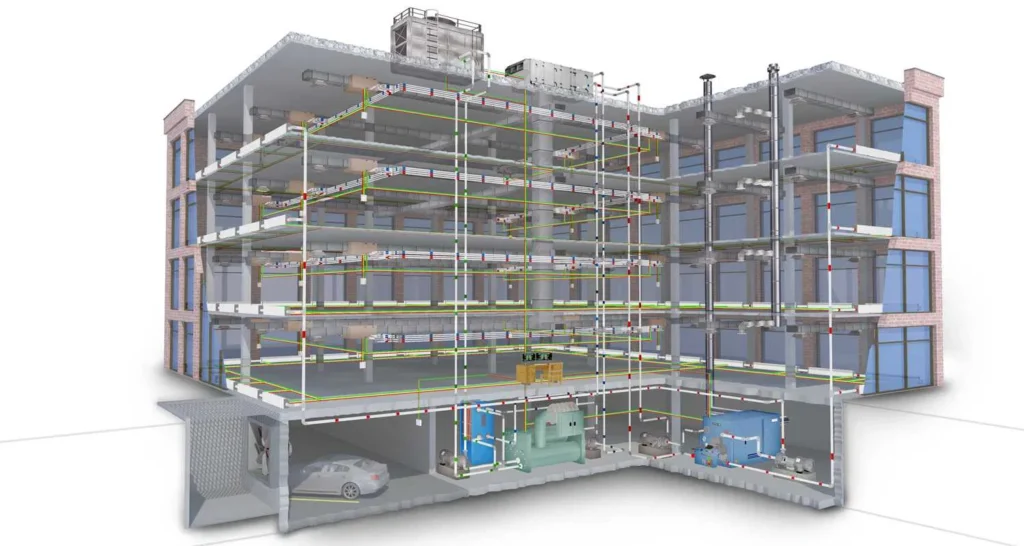

In building construction, MEP plans go beyond being technical documents; they guide how all building systems work together. The value of these plans is demonstrated when all building services must cooperate and not interrupt one another during construction. HVAC systems, along with electrical cabling and plumbing, must be situated together in some places. With these plans, all trades can coordinate, which helps avoid errors and repeat work.

Furthermore, having MEP BIM services makes it easier for everyone on the building team to know what to do. Builders also use this information to verify that they meet the local building requirements. Everything from inspections and the issuing of permits to safety measures depends on the MEP layouts.

Key Components Covered in MEP Plans

Mechanical, electrical, and plumbing are the three areas that come together under the MEP umbrella in building construction. All these elements add unique advantages to keep the space comfortable, safe, and functioning properly.

- Mechanical Systems: This includes HVAC (Heating, Ventilation, and Air Conditioning), refrigeration systems, and ductwork. Proper mechanical planning ensures thermal comfort and indoor air quality.

- Electrical Systems: These plans map out wiring, lighting layouts, power outlets, generators, fire alarms, and communication lines. Efficient electrical design prevents overloads and enhances energy efficiency.

- Plumbing Systems: Detailed plumbing plans cover water supply lines, drainage systems, vent pipes, gas lines, and sanitary fixtures.

In construction, all the MEP plans are combined so everyone can see where each system should run and its size. As part of these plans, designers must do load calculations, create circuit diagrams, choose pipe sizes, and divide the system into zones. Their work results in a complete system for designing each step of a project, hitting every stage from rough-in to finishing.

How MEP Plans Enhance Construction Efficiency

The main advantage of using MEP plans in building construction is better efficiency over the entire project course.

1. Prevents Costly Rework

The plans for MEP in building construction outline every part of the mechanical, electrical, and plumbing systems together. This lower chance of overlapping systems helps prevent extra work, delays, and additional expenses.

2. Streamlines Team Collaboration

When all trades have proper drawings, they can work in harmony. Knowing where to place systems helps everyone avoid confusion at the site and promotes faster decisions during construction.

3. Enables Prefabrication

Accurate MEP planning allows for the prefabrication of components like ductwork, conduit racks, and plumbing assemblies off-site. This speeds up installation, reduces waste, and minimizes on-site labor.

4. Improves Scheduling and Sequencing

By visualizing how systems interact, project managers can better sequence tasks and allocate labor. MEP plans in building construction help avoid workflow bottlenecks and keep the project on schedule.

5. Supports Quality Control

MEP plans serve as a benchmark for inspections and testing. They help teams identify deviations quickly, ensuring system performance, safety, and compliance with building codes.

Benefits of MEP Plans in Building Construction

Implementing MEP plans in building construction brings a wide range of advantages that streamline both project execution and long-term operations. Key benefits include:

- Clash Detection & System Coordination: Prevents physical conflicts between HVAC, electrical, and plumbing systems by clearly mapping out system locations.

- Cost Control & Budget Accuracy: Helps with accurate material estimates, reducing waste, and controlling project budgets from the outset.

- Regulatory Compliance: Ensures all systems are designed to meet local codes and standards, simplifying the approval and inspection process.

- Energy Efficiency: Optimizes mechanical and electrical layouts to reduce energy consumption and improve building performance.

- Streamlined Maintenance & Operations: Provides clear diagrams for future repairs, upgrades, or maintenance, minimizing downtime and improving service efficiency.

Current Trends in MEP Plans

The future of MEP plans in building construction is shaped by innovation, sustainability, and smart technology integration. Below are some key trends:

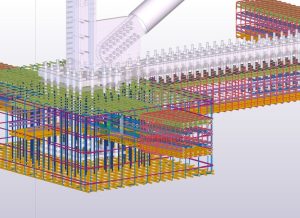

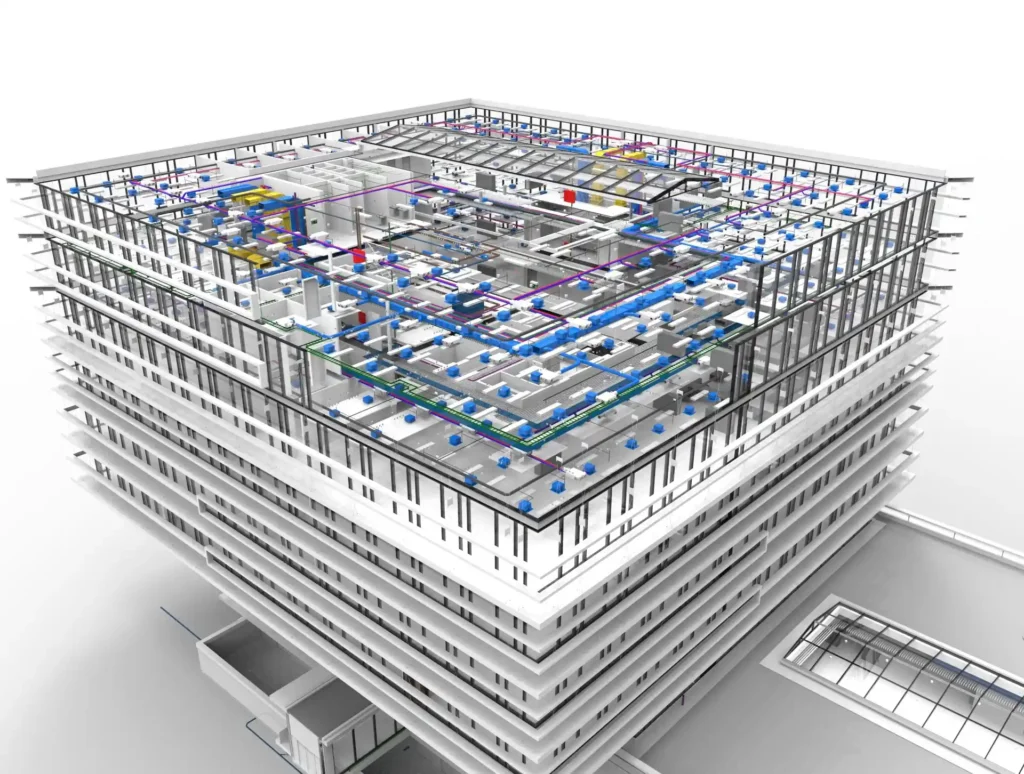

BIM Integration

Building Information Modeling (BIM) pairs precise MEP drafting with advanced 3D MEP modeling, boosting visualization, accuracy, and clash detection across disciplines.

Sustainable Design

Modern MEP plans prioritize green technologies like low-energy HVAC, LED lighting, and water-efficient plumbing to meet eco-certifications.

Cloud-Based Collaboration

Cloud tools and mobile platforms enable real-time access to updated plans and streamlined MEP coordination, improving communication among on-site and remote teams.

Smart Building Technology

IoT sensors and automation are increasingly embedded into MEP systems, enabling energy monitoring, predictive maintenance, and smarter building operations.

Modular & Prefabricated Systems

A growing reliance on pre-assembled MEP modules off-site speeds installation and elevates construction quality, supported by detailed MEP shop drawings.

The Role of Technology in Developing MEP Plans

Technology has significantly transformed how MEP plans in building construction are developed, coordinated, and executed. Gone are the days of 2D paper-based schematics. Today, Building Information Modeling (BIM) is the standard for creating 3D, data-rich MEP models that integrate seamlessly with architectural and structural plans.

With cloud-based platforms and mobile access, field teams can view updated MEP plans in building construction in real time. This digital shift enhances communication, reduces errors, and streamlines change management. In the future, AI and IoT integrations will further enhance how MEP systems are designed and maintained.

Why MEP Plans Are Crucial for Every Building Project

In conclusion, MEP plans in building construction are not just technical drawings—they are the backbone of modern infrastructure. They ensure that a building’s vital systems operate efficiently, safely, and in harmony. These plans reduce construction risk, enhance productivity, support regulatory compliance, and enable cost-effective project delivery.

Ignoring or underestimating MEP planning can lead to long-term issues like poor air quality, electrical hazards, water leaks, and system failures. On the other hand, investing in robust MEP plans in building construction results in energy-efficient, future-ready buildings that meet the demands of users and regulators alike. Find us on Google Maps.

FAQs

What does MEP Mean?

MEP stands for Mechanical, Electrical, and Plumbing. It refers to the three major technical disciplines involved in building design and construction, responsible for ensuring essential services like heating, ventilation, power supply, lighting, water systems, and waste management.

What is MEP in Construction?

In construction, MEP refers to the planning, design, and implementation of mechanical, electrical, and plumbing systems within a building. These systems are essential for a structure’s functionality, comfort, and safety. MEP plans in building construction help coordinate these systems to avoid conflicts and ensure efficient operation.

What Does MEP Stand For?

MEP stands for Mechanical, Electrical, and Plumbing—the core building service systems in residential, commercial, and industrial construction projects. Each component plays a crucial role in making a building habitable and operational.

What is MEP in Engineering?

In engineering, MEP refers to the collective discipline focused on the design and integration of Mechanical (HVAC), Electrical (power, lighting), and Plumbing (water, drainage) systems. MEP engineering ensures these systems are efficient, safe, and well-coordinated throughout the lifecycle of the building.