In the building and construction sector, steel is used as a corner stone material because it is very durable, flexible, and strong. Nevertheless, in more complex structures, fabrication errors in the steel parts may lead to serious delays, cost overruns and safety issues.

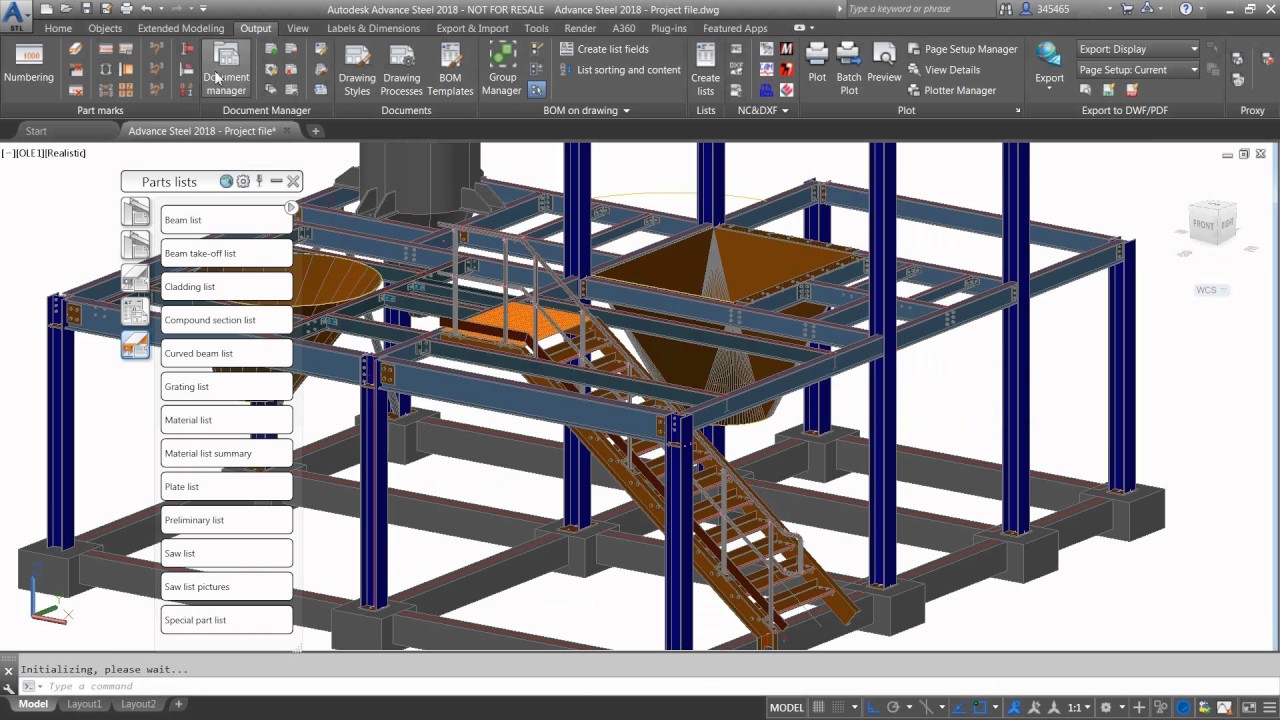

Modern Building Information Modeling (BIM) and Computer-Aided Design (CAD) technologies have been developed to provide the solution of the advanced steel detailing which will immediately decrease these errors, facilitate the working process, and enhance the overall quality of the project.

In this blog, we explore how advanced steel detailing helps reduce fabrication errors, its benefits, and best practices for implementation.

Fabrication Errors in Steel Construction

The errors of fabrication are experienced when the steel components are not produced in the right way because of miscommunication or wrong drawing or human error. Common errors include:

- Incorrect dimensions: Steel beams or columns may not match the exact specifications required, leading to fitment issues on-site.

- Improper cutting or welding: Misalignment during cutting or welding can compromise structural integrity.

- Missing connections or holes: Pre-drilled holes for bolts or welds may be misplaced or missing entirely.

- Material mismatches: Using the wrong grade or type of steel can affect load-bearing capacity.

Such mistakes are not only inconvenient, but may lead to the re-fabrication that may be expensive, project delays, and even structural failures. Conventional 2D drafting techniques tend to propagate such errors since they are very manual in interpretation and provide only a poor view of complicated geometries.

What Is Advanced Steel Detailing?

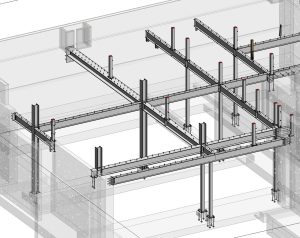

Advanced steel detailing entails development of extremely precise and detailed digital models of steel structures through the use of advanced software application. In contrast to the traditional drafting, the advanced detailing utilizes 3D CAD and BIM platforms to deliver well-defined measurements, geometry and fabrication data.

Key components of advanced steel detailing include:

- 3D Modeling: Offers a complete visualization of the structure, helping detailers understand connections, tolerances, and assembly requirements.

- Automated clash detection: Identifies potential conflicts between steel members or with other building systems before fabrication begins.

- Integration with fabrication machines: Digital models can be directly used for CNC cutting, drilling, and welding, minimizing manual errors.

- Standardized documentation: Fabrication drawings, material lists, and assembly instructions are generated automatically, reducing discrepancies.

By bridging the gap between design and fabrication, advanced steel detailing ensures accuracy, efficiency, and consistency.

How Advanced Steel Detailing Reduces Fabrication Errors

Even minor fabrication mistake in building material in steel construction in modern construction may cause expensive delays, structural issues, and dangers that affect people safety. The old 2D drawings and manual works commonly allow interpretation error, lack of fit or omission. Here is the stage of high-tech steel detailing, which makes use of 3D modeling technology, integration of the BIM, and automated fabrication processes to offer the steel detailing that is exact, precise and error-free.

Including the gap between design and fabrication, the high-end steel detailing not only makes all the components fitted flawlessly but simplifies construction, minimizes waste and saving time and money.

1. Precise Measurement and Alignment

Fabrication errors are caused by a lot of inaccurate measurement. Using the 3D modeling software, all the beams, plates and columns are modeled in real sizes.

- Exact placement of holes and connections: Avoiding the costly mistake of misaligned bolts or weld points.

- Tolerance analysis: Detecting parts that might not fit together due to size discrepancies.

- Automatic updates: Changes in design are automatically reflected in all related components.

This precision drastically reduces the chance of human error during fabrication.

2. Enhanced Visualization and Clash Detection

Advanced steel detailing provides detailed 3D visualizations that enable stakeholders to see the entire assembly before fabrication. This allows engineers and detailers to:

- Detect clashes with other structural elements, piping, or mechanical systems.

- Plan for complex assemblies that are difficult to visualize in 2D drawings.

- Review the sequence of erection to minimize rework during installation.

By spotting these issues digitally, companies can prevent costly on-site adjustments.

3. Streamlined Communication Across Teams

Fabrication errors often occur due to miscommunication between engineers, detailers, and fabricators. Advanced steel detailing improves collaboration by:

- Providing a single source of truth: All team members work from the same digital model, reducing discrepancies.

- Enabling cloud-based collaboration: Changes, comments, and approvals can be shared in real time.

- Integrating with project management tools: Helps track fabrication status, material delivery, and assembly schedules.

This collaborative approach ensures that everyone is on the same page, reducing misinterpretations that lead to errors.

4. Integration with Automated Fabrication

Modern steel fabrication facilities increasingly use CNC machines and robotic welders. Advanced detailing software can:

- Directly feed CNC machines with digital files, eliminating manual input errors.

- Generate precise cutting, bending, and drilling instructions.

- Ensure consistency across all components, especially in large-scale projects.

This automation reduces human errors during fabrication and guarantees that each piece is built to specification.

5. Accurate Material Planning and Management

Another source of fabrication errors is incorrect material estimation or procurement. Advanced steel detailing provides:

- Detailed material lists: Includes quantity, type, and dimensions of each steel component.

- Cost estimation tools: Helps prevent over- or under-ordering materials.

- Waste reduction strategies: Optimizes cutting patterns to minimize scrap.

By managing materials accurately, companies can prevent errors caused by substituting incorrect steel grades or reordering materials mid-project.

Benefits of Reducing Fabrication Errors

In modern construction, even the smallest fabrication error in steel components can lead to costly delays, structural challenges, and safety risks. Traditional 2D drawings and manual processes often leave room for misinterpretation, misalignment, or oversight.

Implementing advanced steel detailing offers a range of benefits beyond just minimizing mistakes:

1. Cost Savings

Re-fabrication, rework, and delays are expensive. Accurate steel detailing minimizes errors and avoids the associated costs. According to industry estimates, preventing even a small number of fabrication mistakes can save hundreds of thousands of dollars on large projects.

2. Improved Project Timelines

Errors can stall construction schedules. Advanced detailing allows for:

- Faster fabrication with fewer interruptions.

- Reduced on-site corrections.

- Timely material delivery and assembly.

Overall, projects can be completed on or ahead of schedule.

3. Enhanced Safety

Fabrication errors can compromise structural integrity, leading to unsafe conditions. Accurate detailing ensures that all components meet design specifications, reducing the risk of accidents during construction and use.

4. Better Quality Control

Advanced steel detailing standardizes processes and documentation. Fabricators can follow clear instructions, resulting in consistent quality across all components. This not only meets client expectations but also enhances the reputation of contractors and fabricators.

5. Reduced Environmental Impact

By optimizing material usage and minimizing errors, projects generate less waste. This contributes to sustainable construction practices, which is increasingly important in modern building projects.

Best Practices for Implementing Advanced Steel Detailing

To maximize the benefits and minimize fabrication errors, construction firms should follow these best practices:

1. Invest in Skilled Detailers

Even the best software cannot replace expertise. Hiring experienced steel detailers who understand structural behavior and fabrication processes is critical. Continuous training ensures that staff stays updated with the latest tools and techniques.

2. Use High-Quality Software Tools

Selecting the right detailing software is essential. Features to look for include:

- 3D modeling with BIM integration.

- Automated clash detection and reporting.

- CNC compatibility for direct fabrication.

- Cloud collaboration and version control.

3. Standardize Detailing Procedures

Establishing standard procedures for creating, reviewing, and approving steel details reduces inconsistencies. This includes:

- Templates for common components.

- Standardized annotation and labeling.

- Version control protocols to track changes.

4. Conduct Regular Reviews and Audits

Even with advanced tools, periodic checks are necessary. Reviewing models for potential errors, verifying dimensions, and auditing fabrication plans can catch mistakes before they become costly problems.

5. Collaborate Early with Fabricators

Early collaboration between designers, detailers, and fabricators ensures feasibility and prevents errors. Fabricators can provide insights on manufacturing limitations, tolerances, and assembly sequences.

The Future of Steel Detailing

The construction industry is moving toward fully digital, automated workflows. Advanced steel detailing will continue to evolve, incorporating AI-driven design optimization, predictive error detection, and real-time fabrication monitoring.

Some trends to watch include:

- AI-assisted detailing: Identifying potential fabrication errors before they occur.

- Robotics integration: Directly linking digital models to robotic assembly lines.

- Augmented reality (AR) on-site: Allowing teams to visualize steel assemblies in real space before installation.

Embracing these technologies will make fabrication errors increasingly rare, while improving efficiency, quality, and safety.

Conclusion

Fabrication errors in steel construction are a persistent challenge for projects in Hauppauge, NY, often impacting costs, timelines, and safety. By leveraging advanced steel detailing, local construction companies can benefit from precision modeling, automated processes, and seamless collaboration.

Reducing fabrication errors with advanced steel detailing ensures higher-quality structures, cost savings, and smoother project execution. For fabricators and construction firms in Suffolk County and the surrounding areas, investing in advanced steel detailing is essential to stay competitive in today’s complex construction landscape.

For expert support in minimizing fabrication errors, local professionals can rely on STRAND Consulting. Contact them at (631) 805-3179 or visit their office at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA. You can also view their location on the map here.