Building Information Modeling (BIM) is redefining the way steel structures are designed, detailed, and delivered. Over decades, steel detailers had to use 2D drawings, manual drafting, and continual consultations with architects and engineers. This usually resulted in mistakes, delays, and increased expenses. BIM has changed all of that.

BIM aids in real-time collaboration with teammates, early detection of issues, and creation of proper shop drawings by utilizing smart 3D models. This blog explores the impact of BIM on steel detailing, its advantages, issues, and the future of construction technology.

What is BIM in Steel Detailing?

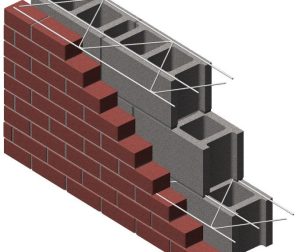

BIM is not merely a three-dimensional drawing. It is a computer process that makes and controls elaborate 3D models of a building. In steel detailing, BIM records each column, beam, and connection as an intelligent object, rather than as a line on paper. Every object contains data such as the size, material, and location. This allows architects, engineers, detailers, and contractors to work with a single model, eliminating miscommunication as every team can view the same version of the project.

From 2D Drawings to 3D Models

Steel detailing no longer involves hand-drawn sketches, but well-developed digital representations. This 2D to 3D journey has radically changed the manner in which detailers, engineers, and contractors collaborate. This change is one of the main reasons why it is important to understand why BIM is now such a fundamental tool in modern construction.

Traditional Methods

Steel detailers had been using 2D plans for many years. These were hand-drawn or simple CAD programmes. Although helpful, these drawings were limited. They represented sizes, but not the means of steel members to interact with plumbing systems, HVAC systems, or electrical systems. The mistakes usually emerged during construction, when they were more costly.

The Shift To 3D

BIM changes this approach completely. BIM builds living 3D models that automatically update when there is a change rather than fixed lines.

Some advantages include:

- All steel components are represented in detail as they will look in reality.

- Structures can be zoomed, rotated, and viewed from any angle.

- New changes are reported instantly on the whole project.

This makes projects more transparent and reduces guesswork for everyone involved.

Accuracy And Error Reduction

Good steel detailing relies on accuracy. Even a single error in a drawing can cause costly delays, waste of materials, and fabrication mistakes. BIM reduces this risk. Elements are interconnected, so when one part changes, updates occur throughout the model. For example, if a beam length is altered, connected bolts and plates adjust automatically. As a result, drawings remain consistent and reliable. Fabricators trust the information they receive, which leads to fewer surprises for contractors during installation.

Clash Detection Before Construction

Clashes between systems were once among the biggest construction problems. The overlapping of ducts, pipes, or conduits with steel members is common. Previously, these mistakes were identified on-site, which meant that teams had to stop work and create a new design.

In BIM, clash detection allows these issues to be detected early. The software highlights conflicts before fabrication begins. Examples include:

- A collapse of a ventilation duct through a beam of steam.

- Plumbing lines are passed through a connection plate.

- Electrical conduits that pass over trusses.

By addressing the clashes in a digital manner, teams conserve time, waste and eliminate expensive on-site adjustments.

Collaboration Across Teams

There are many professionals involved in any construction project, and their success will rely on collaboration. Previously, communication gaps used to result in delays, mistakes, and costly misunderstandings. BIM solves the problem by providing one platform upon which all the team members can communicate and remain aligned throughout the project.

How BIM Improves Communication

Construction involves collaboration among architects, engineers, contractors, and detailers. The past workflow separation between every discipline slowed the process and created communication breakdowns. BIM offers a common model in which all people can work in real time.

Benefits of this approach include:

- Architects modify designs, and detailers are aware of them instantly.

- Connection review is done by engineers to ensure safety.

- Accurate data are used by fabricators to prepare.

Such a common space enhances coordination, minimizes mistakes, and the projects proceed smoothly.

Faster Project Delivery

In construction, time is important. Slow time equates to money, taxation, and schedule shifts. With BIM, the process of steel detailing is much faster as tasks are automated. Shop drawings are produced from the 3D model with no need to redraw plans manually.

Due to the flow of data between the model to fabrication, it takes less time to make steel. Contractors can access credible information earlier, which enables timely installation. The result is reduced project timelines, fewer bottlenecks, and more efficient delivery without sacrificing quality.

Visualization for Stakeholders

Technical drawings cannot be read by all stakeholders. 2D plans usually confuse owners, investors, and non-technical managers. This gets resolved with the use of BIM, which generates realistic 3D clear views.

This helps in several ways:

- The owners are aware of the way the steel frame fits the building.

- The decision-makers accept designs with more assurance.

- Visual data is used by contractors to design safety and site logistics.

This improved visualization facilitates easier communication and makes them all on track before fabrication.

Integration with Fabrication

The steel detailing does not stop at drawings. After the design is done, it will have to proceed to fabrication, where steel is cut, drilled, welded, and assembled. The approach of moving data between drawings to machines makes a massive contribution to accuracy and efficiency. BIM helps eliminate this gap directly by allowing access to fabrication technology through digital models.

Old Method

Fabrication shops once depended on manual data entry. Workers retyped dimensions from drawings into CNC machines, which often led to mistakes.

BIM Method

The fabrication technology relates directly to BIM. The 3D model data is exported into CNC machines, which in turn cut, drill, and weld steel automatically. This eliminates mistakes, enhances the rate of production, and guarantees that each item matches the design. One of the greatest strengths of BIM is the seamless exchange of digital practice models to physical steel.

The Future of Steel Detailing with BIM

BIM keeps improving, and its future is even better. It is becoming more intelligent and powerful with the help of new technologies. For example:

- Artificial Intelligence (AI): Proposes the improved design links and can predict architecture problems.

- Cloud Collaboration: Enables teams around the world to collaborate in real time, working with the same model.

- Virtual Reality (VR): Let stakeholders take a walk in a steel structure before its construction.

With these innovations, steel detailing will be quicker, more accurate, and collaborative than ever.

Conclusion

BIM has transformed steel detailing in New York and Long Island from a manual drawing process into a digital and collaborative system that ensures high accuracy. It improves precision, prevents clashes, and connects directly with fabrication technology to guarantee smooth project execution. By enabling real-time collaboration and clear visualization, BIM reduces errors and speeds up delivery times. As the construction industry across Hauppauge and surrounding areas embraces digital tools, BIM is not just an option—it is the future of steel detailing and the foundation for smarter building practices.

For expert support in BIM and steel detailing services, you can reach Strand Consulting Corporation at (631) 805-3179, stop by our office at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA.