Precision, efficiency, and collaboration are all important in the construction and engineering sector and can make or break a project. Traditional methods, such as 2D drawings and partial communication, allow space for accommodating expensive errors, misunderstandings, and delays. Enter Building Information Modeling (BIM), a technology-based solution that has transformed the process of project delivery by delivering smart 3D models, coordinated project delivery, and data-driven processes.

However, beyond theory, the real test of the worth of BIM is the real-world results. BIM-enabled project case studies not only reflect the issues solved but also the payback or the return-on-investment (ROI), the pre-and-post post-improvements, and the lessons that lead to widespread implementation within the industry.

In this blog, we will look into BIM successful case studies so as to demonstrate how BIM converts problems into opportunities to set a new standard in terms of accuracy, collaboration, and construction excellence.

Why BIM Case Studies Matter

Theoretical arguments on BIM highlight some of the advantages of the technology as including clash detection, visualization, coordination, and efficiency. It is, however, practical applications which persuade decision-makers. Through a BIM analysis, we are able to see:

- ROI and efficiency gains: Quantifiable cost savings and time reductions.

- Problems solved: From design errors to miscommunication across trades.

- Before-and-after transformations: How BIM shifts workflows from reactive to proactive.

Let’s dive into the case studies to see BIM’s value in measurable action.

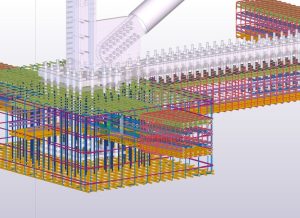

Case Study 1: Connecticut Proton Therapy Center: Outpatient Facility

Project Location: 932 Northrop Road, Wallingford, CT 06492

The Challenge

The Connecticut Proton Therapy Center required no compromise in structural accuracy. Being a specialized outpatient healthcare facility, it required reinforced concrete structures that would be able to sustain the structural and safety provisions.

Rebar detailing in a traditional 2D workflow is subject to errors. Clash, delays, and expensive on-site corrections may be triggered by misinterpretations of slabs, placement, and connections between slabs and beams, as well as columns. Further, it is important to note that coordinating rebar layouts and other disciplines (mechanical, electrical, and plumbing) becomes more complicated in case various teams use siloed documents.

For this project, where patient safety and structural compliance were non-negotiable, relying solely on traditional methods would have introduced unacceptable risks.

The BIM Solution

The project team became involved in Building Information Modeling (BIM), and to be precise, a 3D Revit model detailing rebar. This strategy changed the way reinforcement was pictured, laid out, and implemented.

Key strategies included:

- Color-Coded Rebar Visualization: The model enhanced the simplicity of the bar types, sizes, and arrangements by giving them different colors to make them visible by contractors, engineers, and inspectors. Loss of communication was a great deal minimized.

- Integration with Other Trades: Clash detection was used to find and to resolve conflicts between rebar layout and MEP systems prior to the construction commencing.

- Automated Bar Bending Schedules: BIM created accurate schedules directly out of the model and eradicated manual mistakes and time was saved in the planning and procurement process.

The Results: Before vs. After BIM

- Before BIM: High risk of misplacement, inefficient communication between trades, and costly rework.

- After BIM: Streamlined workflows, improved accuracy, fewer errors, and faster execution.

- ROI Highlights: Reduced field errors, better material management, and efficient labor utilization resulted in significant cost savings and timely project completion.

This case demonstrates how BIM, when applied to structural detailing, can elevate a project’s quality and reduce risks while meeting stringent industry standards.

Case Study 2: Clearwell Tank: Concrete and MEP Model

Project Location: New York, USA

The Challenge

The Clearwell Tank project represented one of the most complex precast engineering projects of the last few years. It involved the creation of two massive tank wells, each measuring a 78′-0″ radius with 44′-0″ high curved walls, topped by a sloping dome slab.

The dome slab was a challenge of its own, and it demanded several pipe connections that would be seamlessly incorporated into the structure. Within traditional processes, this complexity provides an environment that is vulnerable to mistakes, crosslinked connections, construction delays, and rework, which is expensive.

In addition, concrete and MEP systems had to be perfectly coordinated because of the scale and the curvature of the walls. The lack of an intelligent and unified model would have filled the execution with conflicts and design mistakes.

The BIM Solution

In order to solve these issues, the project team used the BIM to develop comprehensive concrete and MEP models and combined all the elements into one digital ecosystem.

Key strategies included:

- Meticulous Coordination of Connections: Every inlet and outlet was modeled to ensure functional accuracy and avoid late-stage conflicts.

- Advanced Clash Detection: The dome slab’s multiple pipe connections were tested virtually, resolving issues before construction.

- Enhanced Visualization of Complex Geometry: BIM provided a clear visual representation of the curved walls and dome structure, making it easier for teams to plan and execute with confidence.

The Results: Before vs. After BIM

- Before BIM: High potential for misaligned connections, scheduling conflicts, and costly errors.

- After BIM: Accurate integration, smooth execution, and a project delivered on time with exceptional workmanship.

- ROI Highlights: The BIM process not only reduced design conflicts but also enhanced team collaboration, proving critical for efficiency, precision, and timely delivery in one of the most complex precast projects of its kind.

ROI Insights Across Both Projects

Both case studies reveal common ROI patterns when BIM is integrated:

- Reduced Errors & Rework: Clash detection and visualization minimized site disruptions.

- Time Efficiency: Automated detailing and coordinated models shortened timelines.

- Cost Savings: Optimized material usage and improved workflows reduced waste.

- Improved Collaboration: Real-time coordination between structural, architectural, and MEP teams avoided delays.

- Quality & Compliance: Enhanced accuracy ensured adherence to codes and standards.

Whether it’s a healthcare facility or a complex infrastructure project, BIM consistently delivers measurable improvements across all phases of construction.

Conclusion

Here in Hauppauge and across Long Island, we’ve seen firsthand that BIM is not just a future trend—it’s already shaping some of the most successful projects in the region. The impact is clear: projects are completed more efficiently, innovation is easier to achieve, and the overall quality is raised to a whole new level.

If you’re considering BIM for your next project, our team at Strand Consulting Corporation can help you achieve the same level of efficiency, innovation, and excellence as these case studies have shown. We’re proud to support projects in our community with the tools and expertise that make a measurable difference.

You can find us at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788. To learn more or discuss your project, give us a call at (631) 805-3179 or visit us online at Strand Consulting Corporation.