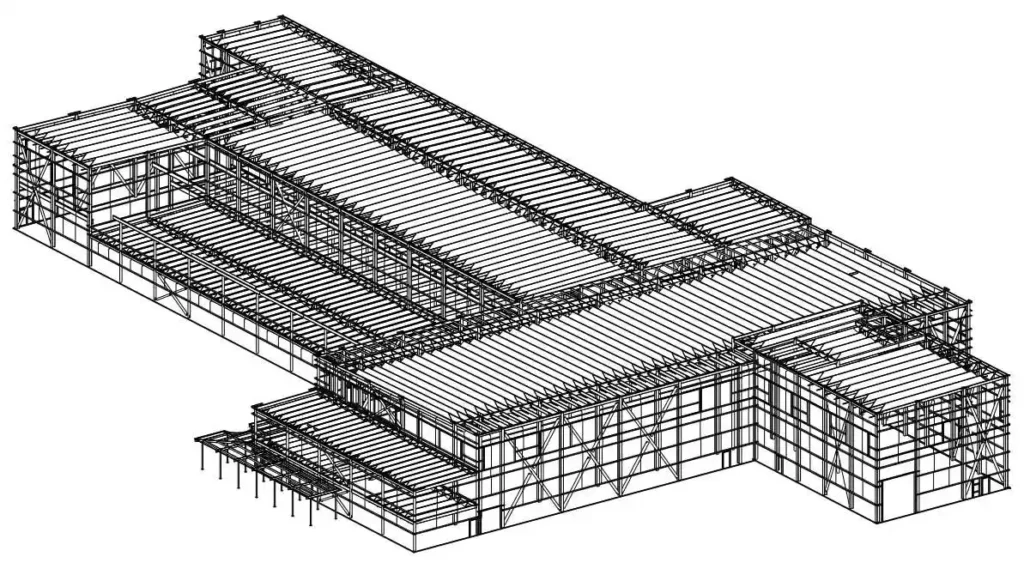

Modern construction heavily relies on steel in skyscrapers, bridges, industrial buildings, and major infrastructural construction. Steel needs, however, to be detailed extremely precisely before it can be manufactured and erected in place, and accomplishing this has traditionally involved converting engineering drawings into shop drawings, erection plans, and material lists. This helps prevent errors in every beam of steel, column, and connection made and erected.

The future of steel detailing lies in the groundbreaking technologies, i.e., Building Information Modeling (BIM), Artificial Intelligence (AI), automation, and international cooperation. This blog will examine how the steel detailing process is evolving, the current problems, and the major trends that will characterise its use in the construction industry in the next few years.

Current Role of Steel Detailing in Construction

Steel detailing is sometimes known as the bridge work between design and construction. It lays out the explicit roadmap needed by fabricators and erectors to bring structural steel elements into existence. In the absence of it, the overall construction process would be inaccurate, disjointed, and inefficient.

Key Deliverables of Steel Detailing

- Shop Drawings: Detailed fabrication drawings for steel workshops to cut, weld, and assemble components correctly.

- Erection Drawings: On-site installation plans guiding construction teams on how to assemble structural steel safely.

- Rebar Detailing: Precise layouts for reinforced concrete structures, ensuring structural strength and durability.

- Bill of Materials (BOMs): Comprehensive lists of materials required, which optimize procurement and reduce waste.

Challenges in Today’s Steel Detailing Practices

Despite the fact that steel detailing is a mandatory component of construction, it also possesses multiple challenges that curtail efficiency and accuracy. These are some of the problems making the industry gravitate towards sophisticated tools and outsourcing models.

Increasing Project Complexity

Modern construction projects, such as high-rise towers, airports, and industrial plants, involve complex geometries and intricate steel connections. Traditional 2D methods often struggle to represent these complexities, leading to errors in fabrication and erection.

Time and Budget Constraints

As developers have to complete their projects within a certain timeframe and on a low budget, detailers are under stress to provide results as soon as possible without limitation to quality. It is often challenging to include such deadlines in manual provision of details or when less available in-house means.

Shortage of Skilled Professionals

The shortage of skilled steel detailers is increasing in most places. These factors, together with the heavy learning curve of more complex software and the availability of outdated tools, also impede companies from developing a robust in-house detailing team.

Error Risks and Cost Overruns

Even small mistakes in detailing—such as a misplaced bolt hole or incorrect dimension—can result in material wastage, fabrication errors, and on-site rework. These errors cause delays and drive up costs, creating frustration across the supply chain.

Limited Collaboration Across Disciplines

Historical tools and systems rarely have continuity between contractors, engineers, and architects. This will create a lack of coordination, design conflicts, and a lack of communication in the detailing procedure.

Future Trends in Steel Detailing

The construction industry is getting more and more pressure to become greener, and steel detailing is not an exception. Designers can also maximize steel consumption because with sophisticated detailing programs, they can make projects as small as possible or insignificant in terms of carbon footprint.

AI-Driven Design Automation

Artificial Intelligence (AI) is transforming the way steel is detailed, automating repetitive processes like connection detailing, clash detection, and error-correction processes. AI-based software can base data on prior projects, predict risks during the design, and design with the most minimum human involvement. This saves a lot of time with accuracy.

Generative Design and Parametric Modeling

Generative design software enables the engineers and detailers to provide design objectives (strength, cost, sustainability), and the software will produce several optimized structural designs. Together with parametric modeling, this trend allows real-time adjustments during the design to facilitate flexibility and efficiency.

AR and VR in Detailing Reviews

AR and VR can evolve and become effective visualization and partnering technologies. With the assistance of AR/VR headsets, clients and contractors will be able to virtually walk through steel structures, look at every detail of the reliefs, and identify issues that might pose a problem during fabrication or erection.

Future Skill Requirements for Steel Detailers

As technology reshapes the steel detailing landscape, the role of detailers is evolving rapidly. Professionals will need to go beyond traditional drafting and acquire skills in Building Information Modeling (BIM), 3D modeling, and digital collaboration platforms. Familiarity with Artificial Intelligence (AI), automation tools, and cloud-based systems will also be crucial for staying competitive.

- Advanced BIM and Software Proficiency: Future steel detailers will be required to not just leave CAD, they will be required to master BIM systems (Tekla Structures, Revit, and Advance Steel).

- Data Analytics and Digital Literacy: With construction evolving to use technical data to make decisions, steel detailers will be required to read and use project data to provide more accurate information at a lower price and anticipate structural durability.

- Cross-Disciplinary Knowledge: Future steel detailers will be in the field of engineering and architecture where technology meets. The knowledge of the material science, sustainability of practice,s and the process of fabricating and making designs will help them create more practical, cost-effective and environmentally friendly designs.

- Soft Skills for Collaboration: With increasing global collaboration, soft skills such as communication, project management, and cultural adaptability will become equally important. Detailers must be able to work with international teams, adapting to varying codes, standards, and workflows.

Emerging Opportunities for Steel Detailing Professionals

The nature of steel detailers is changing as the construction industry changes, and with this change, the tasks of these personnel are changing as well. Their scope of work will be increased as well as their strategic value in the project lifecycle in the future.

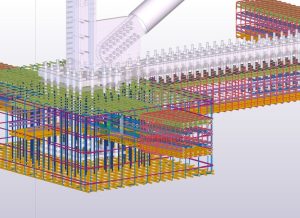

Integration with BIM and Digital Twins

Skilled steel detailers skilled in Building Information Modeling (BIM) will have more and more opportunities to work across disciplines. Since the projects will require digital twin models, i.e., real-time data-driven simulations of real structures, detailers can contribute to it through highly accurate steel models that easily fit within the broader digital ecosystem. This enhances value by reducing lifecycle management, predictive maintenance, and cost forecasting.

Leadership in Sustainability-Driven Design

As the world focuses on sustainable buildings, steel detailers will be in a key position to ensure that they reduce the amount of waste and also ensure that the materials used are more efficient. Their proficiency in detailing is aimed at maximum efficiency in fabrication to save on unnecessary steel waste, transport expenses, and emissions. Practitioners who upskill to meet green building standards (BREEAM or LEED) will be at a competitive advantage.

Remote Work and Global Collaboration

The emergence of developments in cloud-facilitating detailing software implies that consumers of steel detailing can work with engineers, architects, and fabricators without tightening their shipping boundaries. This provides access to global, local projects where detailers can join in mega infrastructural projects and contribute anywhere.

Conclusion

The future of steel detailing in the construction industry is being reshaped right here in New York by advanced technologies, stronger local and global collaboration, and a growing focus on sustainability. With innovations like Building Information Modeling (BIM), automation, and artificial intelligence improving accuracy and efficiency, steel detailing is becoming more seamlessly integrated into the broader construction ecosystem. Additionally, outsourcing and strategic partnerships give firms in Long Island and beyond the ability to access specialized expertise and scale their operations more effectively.

That said, the road ahead also comes with challenges such as developing skilled talent, ensuring data security, and maintaining continuous innovation. Companies that prioritize upskilling their workforce, embrace digital transformation, and encourage collaboration among stakeholders will gain a strong competitive edge in the regional and global market.

If you’re looking for industry expertise and reliable solutions, STRAND Consulting, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA, is a trusted local partner. You can reach them at (631) 805-3179 for professional guidance tailored to the evolving construction landscape.