Mechanical, electrical, and plumbing (MEP) systems are the backbone of a building’s operation in modern construction. Whether it be an HVAC duct system winding its way through structural beams, electrical conduits crossing fire safety routes, or plumbing risers being forced into narrow shafts, there has never been more of a need to ensure appropriate spatial coordination. The ability to afford a margin of error is reduced as the buildings become more and more technologically advanced. Even a single collision of an HVAC duct with a structural column will derail the schedule, swell the budget, and cause a painful on-site rework.

This is the reason why spatial coordination lies at the core of effective MEP design and construction. Builders can inhibit the occurrence of disruption in the downstream and have a seamless project execution by finding, examining, and fixing spatial conflicts prior to the mobilization of teams on site. However, even having the opportunity to use high-tech BIM, spatial coordination is among the largest issues in the AEC market, in particular, in multidisciplinary, highly congested, or complicated projects.

This is a detailed manual to find out why spatial coordination is difficult, the most frequent problems that plague teams, and the successful strategies—both technical and organizational—that help overcome these challenges and achieve high-quality, clash-free MEP integration. For teams aiming to streamline their coordination workflows further, exploring MEP BIM Services can provide the structured support needed to enhance accuracy and project efficiency.

Why Spatial Coordination Is Critical in Complex MEP Systems

Spatial coordination ensures that all building systems fit together within the physical constraints of the structure. Proper coordination results in:

- Reduced rework and fewer RFIs

- Faster installation and streamlined field execution

- Lower project costs

- Higher quality builds with fewer installation errors

- Better system performance and maintenance accessibility

- Improved construction safety

For large and technically dense buildings—like hospitals, airports, data centers, and high-rise towers—MEP systems are highly interdependent. These structures typically feature:

- Narrow ceiling plenum spaces

- Critical routing tolerances

- Strict fire safety zones

- Overlapping MEP trades working simultaneously

- Heavy reliance on prefabrication

The more complex the systems, the more difficult spatial coordination becomes.

Common Spatial Coordination Challenges in MEP Projects

It is necessary to know the common challenges occurring in teams before trying to find solutions to the problems on actual projects.

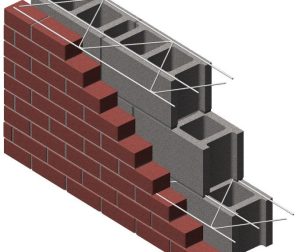

1. Limited Space and Tight Constraints

The ceiling plenums, risers, and shafts usually have much less space than needed to fit all of the MEP elements. Competitors of the same limited spaces are HVAC ducts, cable trays, sprinkler lines, plumbing stacks, communication conduits, etc. The lack of timely coordination in the initial stages makes the installation process disorganized.

2. Late Design Changes

MEP contractors are often supplied with late architectural or structural drawings during the design stage. Even minor adjustments such as moving a beam or reducing a ceiling can spill to significant coordination problems.

3. Lack of Discipline-to-Discipline Alignment

When trade designs are made independently, overlaps are bound to occur. Electrical designs can either take up the space used by HVAC, or plumbing risers can be over fireproofing areas.

4. Inconsistent Level of Detail (LOD)

One common issue in BIM coordination is that the LODs of the trades are mismatched. When HVAC is modeled in LOD 350 and plumbing in LOD 200, it will not be able to find clashes and maintain a spatial realism.

5. Inaccurate or Outdated Models

In case models are not frequently updated with the current versions, teams may end up working with outdated information. This often leads to conflicts during installation and costly redrafting. To avoid these issues and maintain accurate, build-ready models, many teams rely on specialized MEP Drafting Services that ensure every update is captured on time.

6. Poor Communication and Fragmented Workflows

The MEP coordination is a multifaceted process that involves smooth cooperation. The problem with silo thinking is that when engineers, contractors, and BIM teams work in silos, problems tend to be seen when it is too late.

7. Overloaded Coordination Meetings

In most cases, the coordination meetings prove to be ineffective when teams bring too many problems simultaneously or do not have an organised system of prioritisation.

Advanced Techniques for MEP Spatial Coordination

Arranging MEP systems with complexities entails much more than identifying collisions. The contemporary undertakings, particularly hospitals, airports, data centers, and industrial establishments, require greater technical accuracy reinforced by more developed digital plans. The coordination process should be changed to be more proactive with the design integration rather than reactive clash resolution as the building systems become more dense and interdependent. Subsequently are sophisticated methods that the top BIM and VDC companies adopt to guarantee error-free MEP spatial coordination of massive projects.

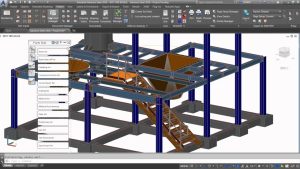

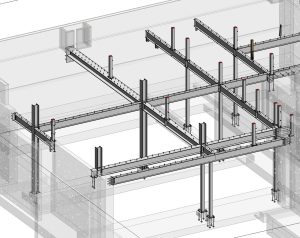

1. Multi-Disciplinary 3D Coordination Sessions

Instead of having trades reciprocate, integrated coordination sessions are held by advanced teams where mechanical, plumbing, electrical, fire protection, structural, and architectural teams interact in real time. Such meetings are based on the federated 3D models, which are seen in real-time, and the conflicts are recognized, analyzed, and solved by the teams – before they transform into costly field problems.

2. Rule-Based Clash Prioritization

Not all clashes are equal. The sophisticated coordination processes apply rule-based clash filters to classify the issues based on their severity, system hierarchy, and priority of construction. An example of this is that structural beams and large mechanical trunks have the tendency to be of priority over smaller branch lines. The automation of such priorities guarantees that the initial attention of the teams is paid to clashes with the greatest construction risk.

3. Utilizing Point Cloud Data for Accurate As-Built Conditions

Scan-to-BIM is able to give laser-precise depictions of the existing circumstances, and this is essential in renovation or retrofit projects. Through overlaying point clouds and design models, it is possible to detect the misalignment of the point clouds, the tight tolerances, or unexpected barriers early. This will improve the accuracy of MEP routing and reduce surprises on-site.

4. Hanger, Support, and Clearance Modeling

Basic coordination does not pay much attention to non-system objects like hangers, seismic supports, insulation clearances, and access zones. Advanced MEP coordination takes them into the model early enough so that their routing decisions are not merely clash-free but installation-ready. Simulation of access zones of valves, panels, and equipment assists in preserving safety and serviceability.

5. Zone-Based and Modular Coordination Strategies

Big projects enjoy the advantage of splitting the structure into different areas and organizing systems separately. Modular coordination is also used in many sophisticated teams that consider racks and modules (and assemblies of corridors) as the unified prefabricated structures. Such a solution enhances decision-making and speeds up and is more consistent on several floors or similar building sections.

6. Automated Routing Optimization Tools

Tools like Revit automation scripts, Dynamo, and AI-driven routing engines enable automated path-finding for pipes, ducts, and conduits. These tools accelerate coordination while ensuring that systems follow optimal paths and avoid high-risk conflict areas.

Conclusion

Spatial coordination of complex MEP systems is one of the toughest challenges in New York’s construction industry, where limited space, overlapping systems, and demanding project schedules require precision and teamwork. That’s why many local contractors turn to STRAND Consulting, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA, for their expertise in BIM-driven workflows, reality capture, and strong coordination protocols. With a dedicated team available at (631) 805-3179, STRAND Consulting helps reduce costly rework, ensure faster installations, and make sure every mechanical, electrical, and plumbing system fits together seamlessly. Ultimately, even the most complex MEP coordination challenges become manageable when guided by experienced local professionals who understand the unique demands of building in New York.