One of the most crucial stages of construction projects is steel detailing. It makes sure that all the steel beams, columns, and connections are outlined accurately before fabrication. Costly errors and time delays may occur in the building without proper detailing.

The standard tool in steel detailing now is the CAD software, which is fast, accurate, and easy to collaborate with. The three common programs include Tekla Structures, AutoCAD, and Advance Steel. In this blog, we will explore all of them in detail.

Why Steel Detailing Needs CAD Software

In the past, steel detailing was done manually, which often led to mistakes, slow production, and poor communication. All of this has changed with modern CAD software, which has made the entire process more accurate, efficient, and transparent. With Computer-Aided Design(CAD), each line is calculated accurately, and the measurement is perfect, including no room for error during construction.

Detailing can be completed quickly using automated tools, which help save project timelines. The software is also designed to help fabricators, engineers, and builders grasp designs more clearly. Most programs are also integrated directly into CNC machines, removing the need for manual input. Today, the use of CAD for steel detailing is no longer optional; it is important for safe, fast, and economical construction.

Tekla Structures for Steel Detailing

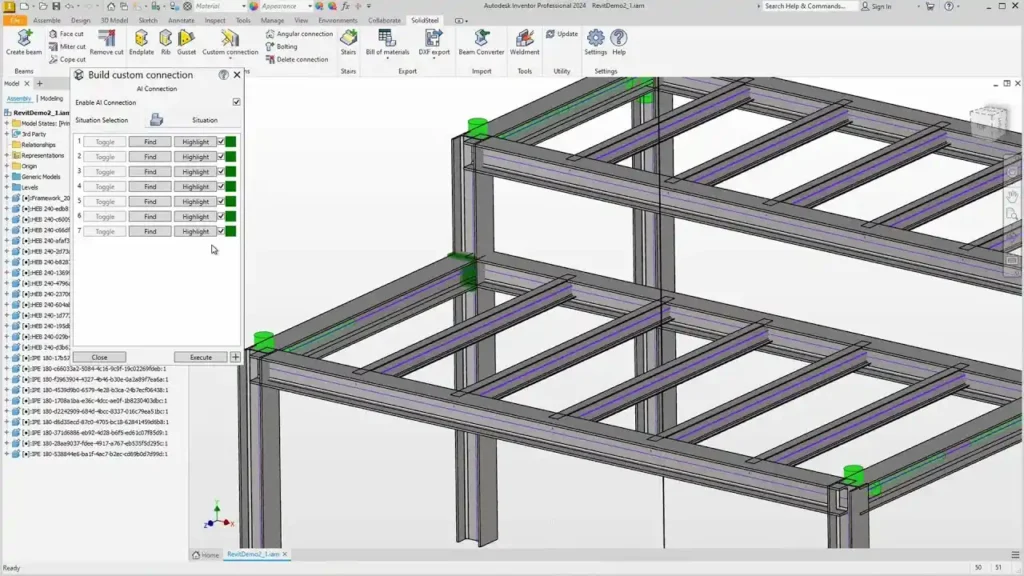

In terms of advanced steel detailing, Tekla Structures is widely regarded as the industry leader. Developed by Trimble, this software not only offers smart drafting features – it creates intelligent 3D models that can be utilized throughout the entire construction lifecycle.

From design and detailing to fabrication and on-site assembly, Tekla offers a comprehensive solution. Due to its robust features and its ability to work with complex structures, you will find it trusted by engineers, fabricators, and contractors all over the world.

Tekla Structures is one of the most efficient software solutions for structural engineering and steel detailing. Unlike traditional CAD tools, it is a fully BIM-based tool, which means that different teams – designers, engineers, contractors, and fabricators – can collaborate on one digital model.

This helps minimize errors, enhances communication, and ensures that everyone is working with the latest information about the project. It is used most often in big projects where accuracy, collaboration, and detail are important.

Features of Tekla

Tekla has many features that are specifically tailored for steel detailing:

- Tekla constructs intelligent 3D models, allowing every detail to be equipped with bolts, welds, and connections. These models are not just visual but embed data that can be used directly for fabrication and construction.

- As Tekla is based on BIM workflows, it promotes seamless coordination amongst teams. For example, an engineer can make changes that can be viewed instantly by the fabricator without misunderstandings.

- Tekla automatically detects design conflicts, such as overlapping steel members or misaligned holes, before they cause problems on construction sites. This saves both time and cost.

- The software produces very detailed shop drawings, bills of material, and schedules. These are automatically re-evaluated whenever the model is reloaded, to guarantee consistency.

On the other hand, Tekla has a few challenges. It costs a lot more than AutoCAD and Advance Steel, and hence, smaller companies would not be able to afford it. It also needs high-performance computer systems to run large models smoothly.

In addition, the steep learning curve creates a big barrier for beginners as they need significant training before benefiting from its use.

AutoCAD for Steel Detailing

AutoCAD, developed by Autodesk, is one of the most popular CAD software programs utilized in the construction industry. Although it was not originally designed as a tool for steel detailing, its flexibility and powerful drafting features have made it a popular selection for many engineers and drafters.

It has become a trusted alternative solution, over the years, for firms that require 2D or 3D drawings but don’t want to invest in specialized detailing software.

AutoCAD offers both 2D drafting capabilities and 3D modeling capabilities. While it may lack the highly specialized steel-specific tools that Tekla or Advance Steel have, it is extremely versatile and can be adapted to a wide range of projects.

Many firms still use AutoCAD for steel detailing due to familiarity, simplicity, and the variety of available file formats. It also applies well to other Autodesk products, making it easier for teams to use their content throughout the various stages of a project.

Features of AutoCAD

Key features that make AutoCAD useful for steel detailing include:

- AutoCAD is popular for creating 2D shop drawings, plans, and sections. It enables detailers to input proper dimensions, notes, and symbols for drawings to be easily comprehended. This precision minimises miscalculation on site and ensures construction quality.

- AutoCAD is capable of 3D modeling, which is used to visualize steel structures. Before construction starts, users can see how the beams, columns, and connections fit. This allows design issues to be found early in the process. Although not as powerful as Tekla, it adds clarity to design.

- AutoCAD allows you to design and save personal templates, blocks, and libraries for steel components. These include bolts, welds, and standard connections that are commonly used on projects. Reusing these templates saves you time, and you can maintain your designs.

- AutoCAD uses widely accepted formats such as DWG and DXF, so files are easily accessible to others. Professionals with other software can still open and review AutoCAD drawings. File compatibility eliminates format or conversion-based delays.

However, AutoCAD does have some limitations. It does not include specialized tools for steel detailing, which means users have to create a custom library or adjust things manually.

Also, large and complex projects can be time-consuming since the software lacks Tekla’s automation or BIM functionality. For companies that need high accuracy and automated processes, AutoCAD may not be enough.

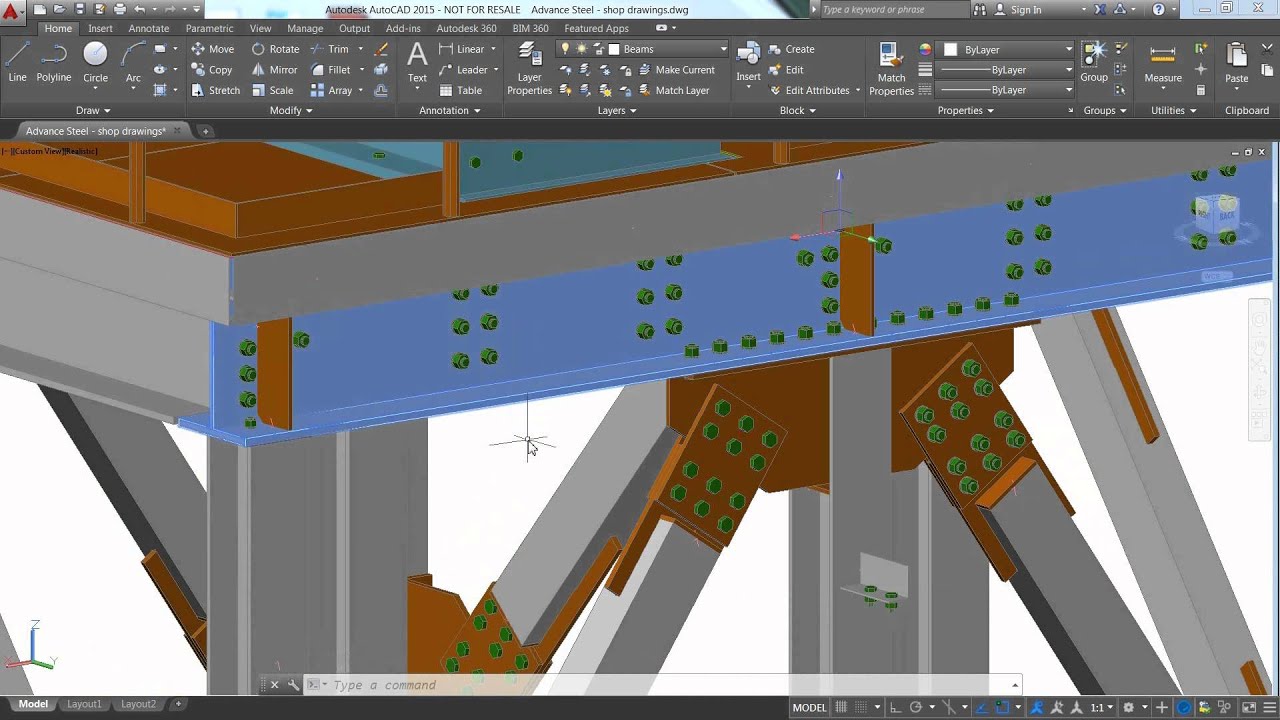

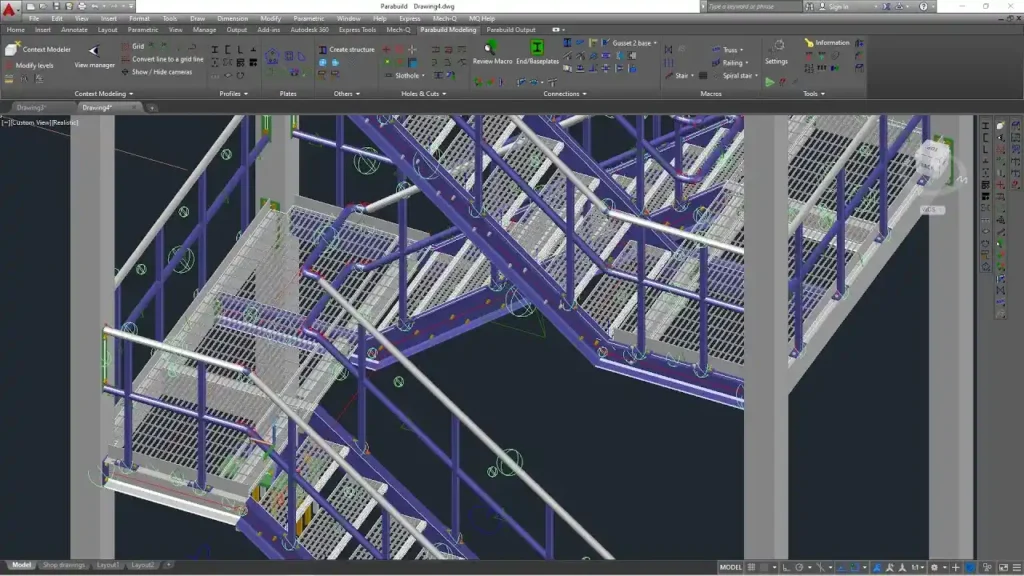

Advance Steel for Steel Detailing

Advance Steel, also from Autodesk, is a tool aimed only at detailing structural steel. Unlike AutoCAD, it is integrated with built-in tools for fabricators, detailers, and engineers, making it a strong competitor to Tekla. Many companies prefer Advance Steel because it offers advanced detailing at a lower cost than Tekla, without being complex.

Advance Steel is based on AutoCAD, but it provides specialized capabilities and functions to deal with steel modeling and detailing. This not only creates a familiar environment for AutoCAD users but also offers powerful tools for shop drawings, connections, and fabrication data.

It also works with BIM workflows, so it can be used with other Autodesk products like Revit. This results in a good trade-off between affordability, usability, and functionality.

Features of Advance Steel

Some of the most important features of Advance Steel include:

- Advance Steel provides powerful 3D modelling tools that are specifically designed for steel detailing. Users can make precise models of beams, columns, plates, and connections. This makes it easier to catch errors before construction, and gives a realistic view of the project.

- The software has a large set of predefined steel connections. Instead of creating connections from scratch, users can apply these connections by default. This saves time and guarantees that the industry standards are present in designs. It also limits the possibility of error in complex joints.

- Advance Steel is based on AutoCAD, which makes it familiar to AutoCAD users. If you are familiar with AutoCAD, this integration makes drafting and modeling easy. It also enhances collaboration (sharing files) between the two platforms. This makes it a nice upgrade for AutoCAD users who need advanced detailing.

- The program can be used to automatically create shop drawings, parts lists, and NC files from the 3D model. These documents will be used by fabricators in the manufacturing process. Automation saves the manual drafting time and accelerates the output. It also guarantees accuracy, which reduces the amount of costly rework during construction.

The drawback is that while powerful, Advance Steel doesn’t get to the same level of detail and performance as Tekla. For very large or complex projects, it may lack performance and accuracy. It also requires a subscription and sometimes has compatibility problems with updates. For companies dealing with extremely complex designs, Tekla might be a better option.

Tips Before Making a Final Decision

Steel detailing CAD software offers a variety of different options; each program comes with strengths and weaknesses. But some factors have to be considered before investing money and time.

1. Understand Your Project Needs

Before you decide what kind of software to buy, you’ll need to consider the type of project. Advanced finishing and collaboration tools are required for large and complex projects, such as bridges, skyscrapers, or industrial plants, and Tekla is a good option for them. For less complex projects or basic drafting, AutoCAD would be enough. Advance Steel sits perfectly between, handling medium to large projects with nice 3D detailing.

2. Consider Training and Support

Different programs come with different levels of learning curve. Tekla is strong but complicated and requires professional training for most users, so they can use it effectively. AutoCAD, on the other hand, is a widely taught program, and many professionals already have a good understanding of it.

Easier for Autodesk CAD users: Advance Steel has the same platform as AutoCAD, making the transition more seamless with less training required.

3. Think About Integration

Integration plays an important role in today’s construction processes. Tekla is a full BIM virtual twin with a direct interface to CNC machines, which makes it ideal for high-tech projects. AutoCAD is good for drafting, but it has limited integration with fabrication tools.

Advanced Steel features good integration with AutoCAD, BIM workflows, and fabrication outputs, making it an excellent middle point for most projects.

| Feature / Software | Tekla Structures | AutoCAD | Advance Steel |

| Modeling | Advanced 3D + BIM | Strong 2D, limited 3D | Specialized 3D for steel |

| Best For | Large, complex projects | Simple drafting tasks | Medium to large projects |

| Ease of Use | Hard to learn | Easy to learn | Moderate, best for AutoCAD users |

| Cost | Very high | Low | Moderate |

Conclusion

Steel detailing software is one of the best tools for improving accuracy, speed, and cost control in construction projects across New York. Popular options like Tekla, AutoCAD, and Advance Steel are widely used, but each serves a different purpose. Tekla is ideal for very large and complex projects that require a high level of precision. AutoCAD, on the other hand, is easy to use, affordable, and adaptable, making it a great fit for smaller projects. Advance Steel strikes a balance between cost and specialization, offering excellent steel details at a reasonable price.

At the end of the day, your choice depends on the size of the project, your budget, and your long-term detailing goals. For expert guidance and tailored steel detailing solutions in Hauppauge and the surrounding areas, you can always rely on STRAND Consulting. Visit us at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA, or call us directly at (631) 805-3179 to discuss your next project.