In reinforced masonry construction, shop drawings play a critical role in translating design intent into buildable, code-compliant reality. This is particularly true in the case of doubled curtain vertical reinforcement in CMU walls where arrangement and spacing of the bars, cover, and constructability is much more complicated compared to single-curtain systems.

This blog is a practical and detailed step-by-step approach to the preparation, reviewing, and use of shop drawings of double curtain vertical rebar in CMU to avoid expensive mistakes and guarantee structural performance by engineers, contractors, detailers, and inspectors.

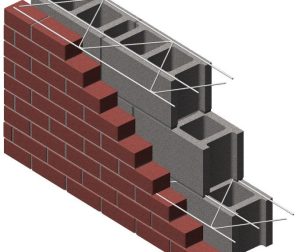

Understanding Double Curtain Vertical Reinforcement in CMU

Double curtain reinforcement has the two parallel layers of vertical rebar installed in a CMU wall, one close to the face shell, and the other, close to the other face shell. In contrast to those of single-curtain systems where reinforcement is concentrated in the cell, the reinforcement of the walls of the doubled curtain is spread near the two cell sides.

This configuration is commonly used when:

- Walls are thick (10 in., 12 in., or greater)

- High bending moments are present

- Seismic or wind loads are significant

- Structural walls act as shear walls or retaining walls

- Increased ductility and crack control are required

Why Shop Drawings Are Critical for Double Curtain CMU Walls

Because CMU units were not originally designed to accommodate two vertical bars per cell, precise detailing is essential. Poorly prepared shop drawings often lead to:

- Insufficient concrete cover

- Bar congestion preventing proper grout flow

- Misaligned reinforcement in the field

- Code violations discovered during inspection

Well-developed shop drawings resolve these issues before construction begins.

Purpose of Shop Drawings in Reinforced Masonry

Shop drawings are an essential part of the reinforced masonry construction; they are necessary to convert the structural design documents into an easily readable, field constructible instruction. Although construction drawings establish general purpose, shop drawings are the means of specifying the reinforcement layouts, dimensions and installation requirements that will be used to implement that purpose correctly, particularly in complicated systems like reinforced CMU walls.

In reinforced masonry, the shop drawings make clear how reinforcement should be put in CMU cells such as the size of bars used, spacing, positioning, lap splices, and necessary cover by concrete. They also organize reinforcement in concert with CMU unit types, bond beam, lintel and grouting operations, minimizing ambiguity and eliminating field improvisation.

- Exact bar locations relative to faceshells

- Bar size, spacing, and lap splice details

- Required concrete cover

- CMU unit type and cell configuration

- Grouting sequence and lift heights

They also allow coordination between structural engineers, masonry contractors, and inspectors.

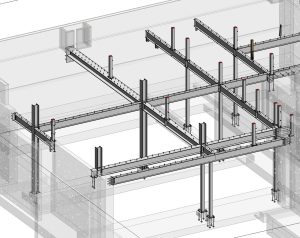

Key Information Required on Shop Drawings

When preparing shop drawings for reinforced masonry, particularly for complex systems like double curtain vertical rebar in CMU walls, it is essential to include all critical information that ensures accurate field installation and code compliance.

1. CMU Wall Configuration

Shop drawings should clearly identify:

- Wall thickness and CMU size (e.g., 12x8x16)

- Unit type (standard, open-end, bond beam)

- Cell layout and usable cell width

Including enlarged wall sections helps verify that two vertical bars can physically fit within the selected CMU unit while maintaining cover.

2. Vertical Rebar Layout

For double curtain systems, drawings must show:

- Inside and outside bar locations

- Distance from each faceshell to rebar centerline

- Clear spacing between the two bars

Bars are typically offset toward each faceshell rather than centered, which must be dimensioned, not assumed.

3. Rebar Size and Spacing

Clearly specify:

- Bar size for each curtain (e.g., #5 interior, #5 exterior)

- Vertical spacing (e.g., 16 in. o.c., 24 in. o.c.)

- Any variation by wall zone or elevation

If bar sizes differ between curtains, this distinction must be unmistakable on the drawings.

Concrete Cover Requirements in Shop Drawings

One of the most significant details to be covered in the shop drawings of reinforced masonry is concrete cover. The adequate cover prevents the corrosion and ensures the proper bond with grout as well as offers fire resistance, which is essential to the long-term durability and structural performance of CMU walls.

Importance of Accurate Cover Dimensioning

Concrete cover is one of the most common inspection failures in double curtain CMU walls. Shop drawings must explicitly show:

- Minimum cover from exterior faceshell

- Minimum cover from interior faceshell

- Cover from webs and adjacent reinforcement

Failure to dimension cover often results in bars drifting during construction.

Typical Cover Challenges

- Exterior exposure increasing required cover

- Thick webs reducing usable cell width

- Conflicts between cover and grout flow

Shop drawings should demonstrate compliance with applicable masonry codes before construction begins.

Detailing Bar Supports and Positioning Devices

In reinforced masonry construction, especially for double curtain vertical rebar in CMU walls, proper bar support and positioning are essential to maintain design intent during installation and grouting. Without adequate support, vertical bars can shift toward the center of the cell or toward one faceshell, reducing concrete cover, creating grout voids, and compromising structural performance.

Double curtain reinforcement cannot rely on gravity or friction alone. Shop drawings should identify:

- Rebar positioners or spacers

- Tie wire requirements

- Methods for maintaining bar separation during grouting

Without proper supports, bars tend to migrate toward the center or faceshell, reducing cover and structural effectiveness.

Coordination with Bond Beams and Horizontal Reinforcement

In reinforced masonry walls, vertical reinforcement must work in harmony with bond beams and horizontal reinforcement to ensure overall structural integrity. Shop drawings play a critical role in coordinating these elements, particularly in double curtain vertical rebar systems where congestion can be a significant challenge.

Double curtain vertical reinforcement must integrate seamlessly with horizontal reinforcement. Shop drawings should show:

- Interaction between vertical bars and bond beam reinforcement

- Clearances at intersections

- Hooking or termination requirements

Poor coordination at these intersections is a common source of constructability issues.

Grouting Considerations Reflected in Shop Drawings

Grouting is a critical step in reinforced masonry construction, ensuring that vertical and horizontal reinforcement is fully embedded and that loads are properly transferred between steel and masonry. In double curtain vertical rebar systems, shop drawings must clearly reflect grouting requirements to prevent voids, honeycombing, or inadequate bond.

Grout Type and Placement Sequence

Shop drawings should note:

- Fine or coarse grout selection

- Maximum grout lift heights

- Required consolidation methods

Congested reinforcement requires special attention to grout flow and placement sequencing.

Inspection and Cleanout Provisions

For tall or heavily reinforced walls, drawings should include:

- Cleanout locations

- Inspection openings

- Temporary bracing notes

By detailing grout type, placement, and inspection points, shop drawings help ensure that reinforcement is fully encapsulated, structural performance is achieved, and construction proceeds efficiently without costly rework.

Final Thoughts

Shop drawings for double curtain vertical rebar in CMU walls are not optional, they are essential. The complexity of placing two layers of reinforcement within masonry units demands precise detailing, clear communication, and thoughtful coordination.

By investing time and expertise into accurate shop drawings, project teams can confidently construct reinforced CMU walls that meet both structural and durability expectations.