Concrete masonry unit wall is the most popular and reliable form of construction used in homes, businesses, and industrial premises. These walls are made out of big rectangular blocks, also known as concrete masonry units; they are favored due to their strength, durability, and affordability.

CMUs are also versatile, featuring as many shapes and sizes as finishes, thus able to suit the needs of any project in particular. CMUs offer improved sound insulation, fire resistance, and structural durability, making them suitable for designing a house, an office building, or a large industrial plant.

This comprehensive guide will cover all aspects of CMU walls, including various types, standard sizes, shapes, wall design, and construction requirements.

Introduction to Concrete Masonry Unit Walls and Their Importance

Concrete masonry unit (CMU) walls are constructed using concrete masonry units or concrete precast rectangular units made from a concrete aggregate mixture (often a mix of sand or gravel and water). These units are created in standard, uniform sizes and may be hollow or solid, depending upon their purpose in the project. Due to their modularity, concrete masonry unit construction can be relatively faster, more efficient, and cost-effective than many other forms of building.

The main advantage of CMU walls is their versatility. They may be constructed as either bearing walls, which support the structural weight of a building, or as non-bearing walls, which are used as partitions or dividers. This versatility means that they can be used in households, commercial buildings, industries, and other large industrial works.

In addition to performance, Pro of CMU walls are regarded as highly robust, strong, fire-resistant, and versatile. When properly designed, they provide a sustainable, secure, and cost-effective solution in modern building design.

Different Types of Concrete Masonry Units Used in Construction

Concrete masonry units are available in a wide range of sizes and shapes, which are used in different ways depending on the project. Selecting the most suitable one is also important as it determines the strength, durability, and appearance of the walls. Whether it is lightweight blockwork partitions or heavy-duty load-bearing blocks, concrete masonry unit construction provides a solution to a number of structural and design demands.

Hollow Concrete Masonry Units

The hollow blocks are also lighter as their cores are empty. These concrete masonry units are cost-effective, easy to handle, and often used in non-load-bearing walls, although they can be reinforced by grout and steel bars to strengthen them accordingly.

Solid Concrete Masonry Units

Solid blocks are denser and heavier, so they are suitable concrete masonry units in load-bearing walls and foundation applications. They give great fire resistance and are soundproof in addition to structural support.

Split-Face Concrete Masonry Units

Split-face concrete masonry units are typically employed in exterior construction. They are rough and stone-like, so their coating is stronger and attractive, and therefore there is no need for extra covering up like painting and cladding.

Lintel and Bond Beam Units

Lintel blocks are concrete blocks that are manufactured to be laid above windows and doors. They assist in supporting the weight of the wall above these openings.

Bond beam components contain special channels, in which steel bars (rebar) and grout are placed. This makes the wall Stronger and more stable. Lintel and bond beam units provide additional support to the structure.

Standard Concrete Masonry Unit Dimensions and Sizes

The concrete masonry unit dimensions are significant when it comes to wall construction. Block sizes also influence the thickness of walls, strength, load-bearing capacity, and other factors. The selection of the right dimensions would provide structural stability, as well as efficiency in construction.

| Nominal Size (inches) | Actual Size (inches) | Common Use |

| 4 x 8 x 16 | 3 5/8 x 7 5/8 x 15 5/8 | Used for interior partitions and non-load-bearing walls |

| 6 x 8 x 16 | 5 5/8 x 7 5/8 x 15 5/8 | Medium-thickness walls, suitable for moderate strength needs |

| 8 x 8 x 16 | 7 5/8 x 7 5/8 x 15 5/8 | Industry standard, commonly used for load-bearing walls |

| 12 x 8 x 16 | 11 5/8 x 7 5/8 x 15 5/8 | Provides extra strength for heavy-duty and structural walls |

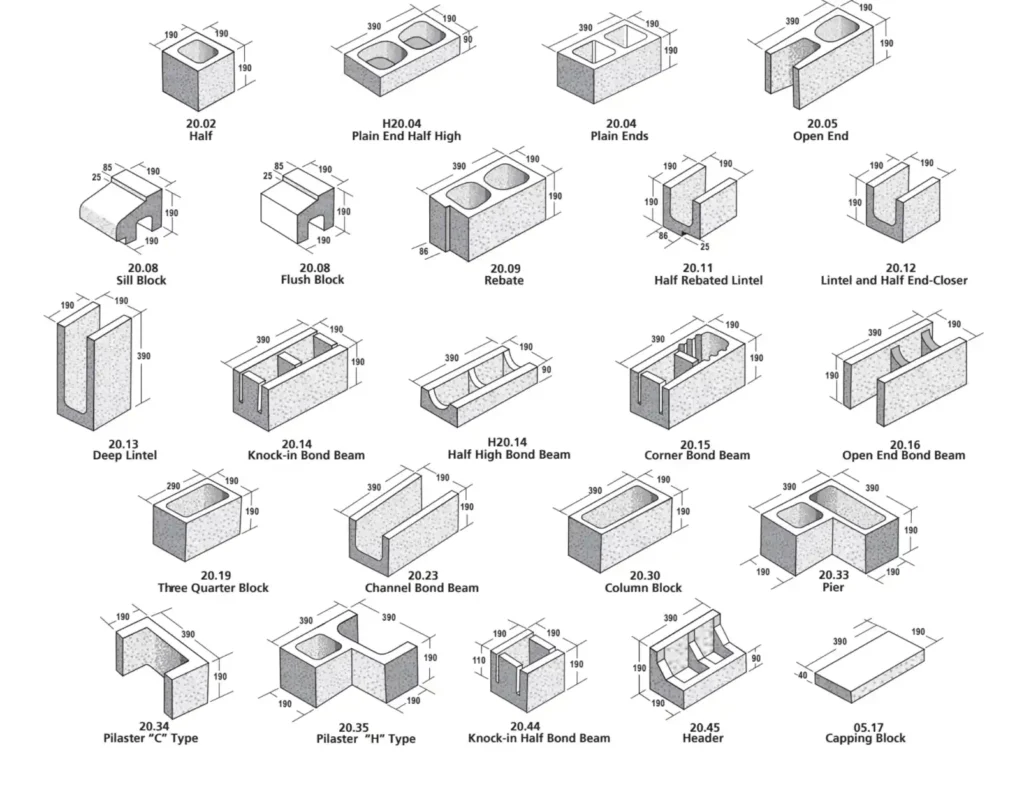

Common Concrete Masonry Unit Shapes and Their Applications

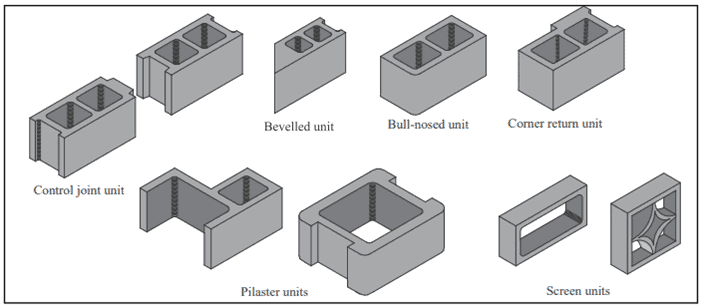

The concrete masonry units’ shapes vary widely to fit various building designs and needs. All these shapes have definite purposes and can add strength and a better outlook to the wall.

Examples of common concrete masonry unit shapes with their applications are:

- Stretcher Units: The stretcher blocks are the most widespread type of concrete masonry. They are inserted into walls, central and end-to-end, as the primary wall structure.

- Corner Units: Corner blocks are made to fit at the ends or corners of walls. They add a finishing touch to the wall and seal the joint between two walls.

- Jamb Blocks: Jamb blocks go around doors and windows. They are designed to receive frames and add strength to the weak parts of a wall.

- Bullnose Blocks Bullnose blocks have rounded corners rather than sharp ones. They are commonly used where people may brush against the wall, like hallways, to make the finish smoother and safer.

- U-Shaped Blocks: U-shaped blocks (or channel blocks) have a channel going through the block. This groove creates room to place reinforcement bars (rebar) and grout, which enhance the wall and stabilize it.

Using the right concrete masonry unit shapes helps your concrete block masonry units fit together properly, making the wall more stable and improving its appearance.

Key Elements in Concrete Masonry Unit Wall Design

The concrete masonry unit wall design should reflect the needs of the building in terms of strength, the weight it will support, insulation, and appearance. The most important design elements are:

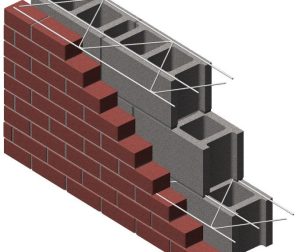

- Reinforcement is one of the most important components of CMU wall design. It increases the strength and stability of the wall by placing steel reinforcement bars (rebar) vertically or horizontally through the blocks, so the wall will be more resistant to pressure and external forces.

- The other important consideration is grouting, whereby the hollow cores of CMUs are filled with grout. This hardens the wall, increases its strength to carry loads, and also its overall strength.

- The finishing of CMU walls is also significant, as it has an influence on protection and appearance. Depending on the needs of the project, the walls can be painted, coated with stucco, or left uncovered. Decorative finishes, e.g., split-face CMUs, may need no additional cladding to provide a decorative appearance.

- Modern concrete masonry unit walls can also be insulated to enhance energy performance. This not only makes CMU walls durable and strong, but also makes them more sustainable in terms of lower heating and cooling expenditures.

Essential Concrete Masonry Unit Wall Details for Safety and Strength

A concrete masonry unit wall detail is vital in construction because it secures the walls that are strong, safe, and constructed as per the requirements of engineering and architecture. These are intricately designed to ensure that the wall can support loads, withstand environmental pressures, and last many years.

Among the most crucial features is the footing design that ensures a stable and firm foundation of the wall. A good wall cannot stand without a good foundation. The other important component is the reinforcement placement, in which steel bars (rebar) are put either vertically or horizontally within the CMUs. This reinforcement significantly enhances the carrying capacity of the wall when exposed to heavy loads or to withstand earthquakes.

Engineers install control joints at specific intervals. These are intended, minor gaps which allow the concrete to stretch and contract naturally, preventing cracking at random points along the wall. Besides this, the thickness and type of mortar are taken seriously to ensure that the blocks adhere to each other, which has a direct effect on the wall’s strength and durability.

Lastly, the wall is reinforced with a grout filling technique by construction builders. They deposit the grout in the holes of CMU blocks to support the wall in a better way and handle heavier loads. All these measures in combination ensure that all concrete masonry unit walls are safe, durable, and strong, besides satisfying design and structural requirements.

Practical Applications of Concrete Block Masonry Units in Building Projects

Concrete block masonry units (CMUs) are known for their versatility and strength, making them a popular choice in many types of construction projects. Their modular design allows for easier handling, faster installation, and reduced material waste, which makes them both cost-effective and reliable.

- Foundations Walls: CMU is widely used on foundation walls due to its strength and durability as a base foundation. They can be used to transport heavy loads, making them safe to use in the long term.

- Basement Walls: Concrete block masonry units are quite common in basement constructions because they can sustain the pressure of the soil, and they can offer a barrier to water when they are used with appropriate waterproofing methods.

- Retaining Walls: These blocks can be used in retaining walls, either in a landscape or in infrastructure. They are heavy and stable, thus ideal for retaining soil and producing flat surfaces on hilly grounds.

- Fire-Rated Walls: A major advantage of concrete masonry unit walls is their fire-resistance. They reduce the spread of flames, which makes them safe in commercial, industrial, and residential structures.

- Soundproof Structures: CMUs are the perfect choice when noise management is concerned. Their mass and density limit the passage of sound, making them perfect in schools, theaters, factories, or buildings close to a busy road.

Overall, the use of concrete block masonry units ensures strength, durability, and efficiency while meeting both structural and architectural needs.

Conclusion

Concrete masonry unit walls remain one of the most dependable choices in construction because they balance strength, affordability, and versatility. With a wide variety of concrete masonry unit types, shapes, and standard dimensions, builders across Hauppauge and nearby Long Island communities can design walls that meet both structural and aesthetic needs. When properly planned and reinforced, CMU walls provide excellent resistance to fire, sound, and harsh weather conditions, making them ideal for homes, offices, factories, and large-scale industrial projects throughout New York.

Attention to detail—such as correct footing design, reinforcement placement, and insulation—ensures that every CMU wall performs at its highest potential. Beyond durability, CMUs also allow architects and contractors in Suffolk County to create cost-effective walls that reduce waste and speed up construction.

At STRAND Consulting, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, we specialize in guiding clients through every stage of concrete masonry unit wall construction. Whether your project is small or large, our Hauppauge-based team delivers expertise that ensures safe, strong, and long-lasting results. Call us today at (631) 805-3179 to discuss your next build.

FAQs

What is a Concrete Masonry Unit wall?

A concrete masonry unit wall is built using precast concrete blocks (CMUs) stacked with mortar. These walls are highly durable, fire-resistant, and cost-effective. In concrete masonry unit construction, they are widely used in residential, commercial, and industrial buildings for both structural and non-structural applications.

What is the difference between a concrete wall and a masonry wall?

A concrete wall is created by pouring liquid concrete into forms, resulting in one continuous surface. A masonry wall, however, is made by stacking blocks, bricks, or stones. In concrete masonry unit construction, CMUs are commonly used because they provide strength, durability, and design flexibility.

What are the disadvantages of concrete masonry units?

Concrete masonry units can be heavy, making transportation and handling difficult. In concrete masonry unit construction, skilled labor is often required, which increases costs. They also limit design flexibility for curved or irregular structures compared to poured concrete or lighter alternatives, reducing architectural possibilities.

What is the difference between unit masonry and concrete unit masonry?

Unit masonry includes walls built from bricks, stones, or blocks. Concrete unit masonry specifically uses CMUs, offering higher strength, fire resistance, and durability. In modern concrete masonry unit construction, CMUs are preferred because they speed up installation and allow more versatile design options for buildings.