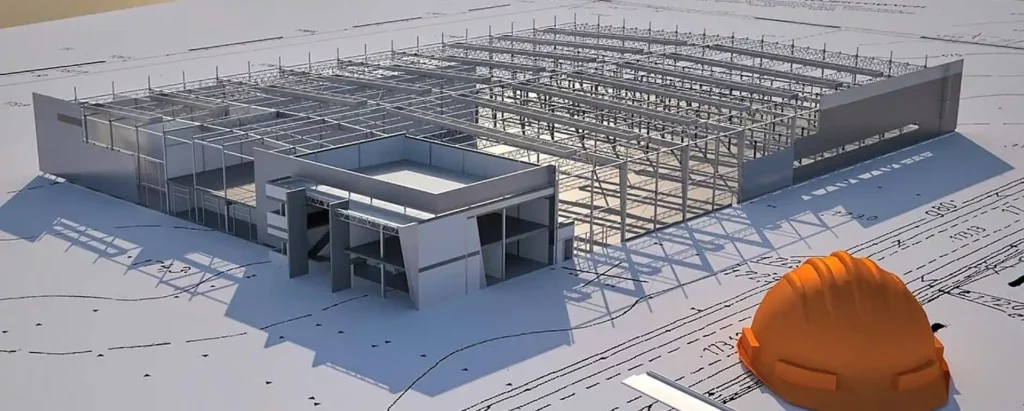

Steel is used in the construction of modern buildings, such as skyscrapers, industrial plants, bridges, and warehouses. The steel detailing is the process that is behind every steel structure. This is a highly specialized service of drawing detailed plans and drawings that are used to fabricate and erect steel members with pinpoint accuracy.

Outsourcing has become a strategic tool that businesses use in the contemporary competitive business world to ensure that they optimize their resources and enhance efficiency. Outsourcing steel detailing services allows the companies to not only save money but also access professionals, technology, and expedited completion of projects. This blog delves into the numerous advantages of outsourcing steel detailing and why it has emerged as one of the options among construction companies across the globe.

Understanding Steel Detailing

Let us first of all define the concept of steel detailing and why it is a critical part of construction before discussing the benefits that come with outsourcing.

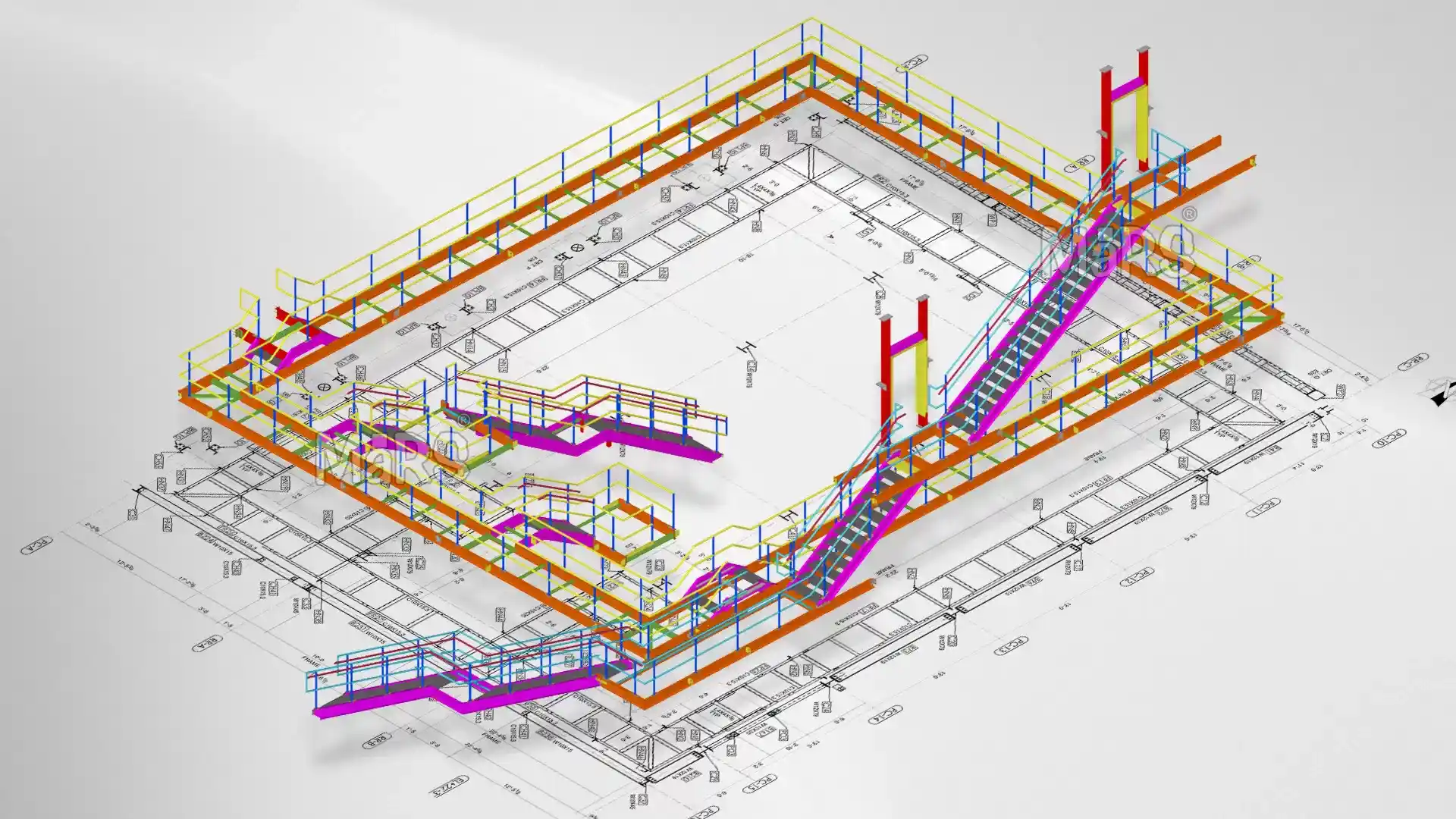

Steel detailing refers to producing detailed drawings and models which are provided by fabricators and erectors to make and assemble steel fabrication and assembly. These drawings contain all the measurements required, material specifications, weld, and bolt and connection that obtain the raw steel into a completed structure.

Key Deliverables in Steel Detailing

- Shop Drawings: Highly detailed fabrication drawings that guide workshops in cutting, drilling, welding, and assembling steel parts.

- Erection Drawings: Instructions for site crews on how to position, install, and connect steel members safely.

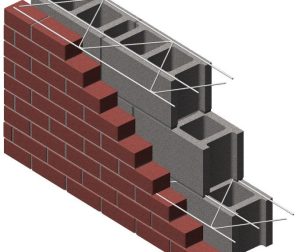

- Rebar Detailing: For reinforced concrete structures, providing layouts for steel reinforcement bars.

- Bill of Materials (BOMs): Accurate material lists to optimize procurement and minimize waste.

What is Outsourcing Steel Detailing?

With the basics of steel detailing in place, we shall now look at the meaning of outsourcing in this regard.

Outsourcing steel detailing involves the recruitment of external experts or firms 8 externally, usually in a foreign country, to perform the work of shop drawing, erection drawing and 3-D modeling compared to the situation when only an in-house team is involved. A number of construction and engineering companies use the method to save money, enhance productivity and tap into world talent.

In-House Detailing vs. Outsourced Detailing

- In-House Detailing: This method involves the company employing full-time detailers, purchasing costly CAD/BIM software, offering continuing training, and dealing with project schedules in-house. This provides control, but is accompanied by high overhead costs.

- Outsourced Detailing: Incorporates collaborating with other detailing companies with professionals in business already possessing their skilled engineers, together with their advanced equipment and set of processes. Firms are not required to commit resources in the form of long-term agreements before they access the services.

4. Key Benefits of Outsourcing Steel Detailing Services

Steel detailing outsourcing has become a strategic decision among construction firms, contractors and even engineering firms. In addition to cutting on the cost, it allows access to world expertise, better tools, and better project delivery. We can discuss the key advantages in the following way:

Cost Efficiency and Savings

Quick cost-cutting is one of the clearest advantages of outsourcing. It is costly to employ and educate in-house steel detailers, acquire high-end software such as Tekla Structures or AutoCAD, and have dedicated infrastructure. Through outsourcing, the businesses cut these overheads and can only pay for services when indicated.

Access to Skilled Expertise

Outsourcing partners specialize in steel detailing services alone. They have well-trained professionals who follow the international standards AISC, BS, and IS codes, and Eurocodes.

Such an availability of professional expertise means that all shop drawings, construction plans, and 3D models are accurate and devoid of errors. Outsourcing firms, by virtue of their management of various projects across different regions of the world, cover industries with experience and problem-solving skills that an in-house team might not have at all times.

Advanced Technology and Tools

Principal outsourcing firms invest in state-of-the-art technology that includes Tekla Structures, SDS/2, Revit and AutoCAD, and Advance Steel. They are the tools with high-level accuracy of the 3D model, the possibility to detect clashes, and the lack of integration between BIM.

Through collaboration with an outsourcing company, organizations benefit from having access to these tools of premium quality without the need to purchase expensive software. The outcome is higher accuracy, less rework, and an easy pattern of cooperation among engineers, planners, and fabricators.

Improved Accuracy and Quality

Any mistakes made during steel detailing may result in material wastage, delay of the project, and expensive rework. Because the outsourcing firms have stringent quality assurance measures, the errors are minimal. Their teams are oriented and trained on the guidelines of certain projects, standards, and quality checklists of industries.

It is also to make certain that each drawing and each material list is rendered to the utmost standards of accuracy and conformit,y minimizing risks in fabricated and erected phases.

Faster Turnaround Times

Time equals money in the current construction industry, which is a fast paced environment. Outsourcing firms are usually available across various time zones implying that the business may continue even when the client is on vacation.

This follow-the-sun paradigm expedites time-to-market. Bulk workloads and hard deadlines can equally be handled by large outsourcing teams so that their projects do not stall.

Scalability and Flexibility

The outsourcing has the advantage of enabling a company to expand and reduce resources depending on conditions in a project. With any bolstering and large-scale plant, whether it is a humble residential assignment or a colossal industrial endeavor, the outsourcing companies are in a position to affix the dimension proportionate to the demands.

Such flexibility spares the companies the burden of employing, developing or dismissing internal employees through changes in workload.

Focus on Core Business

Steel detailing can be quite costly in terms of time and resource management. Outsourcing will allow companies to prioritize their in-house staff toward the work that they should be governing and concentrate on the core processes, which encompass: customer communication, project management, site execution, and innovation.

Outsourcing also lessens the amount of management and enables the managers to focus on growing the business and customer satisfaction.

Risk Mitigation

Recognized sources of outsourcing distribute the responsibility of deliverables in projects. Sometimes it is a contract that has quality guarantees, confidentiality, and delivery timelines because it is under accountability.

Also, outsourcing can be used to reduce the risks associated with unexpected staff shortages, knowledge voids, or compliance challenges. Businesses with sound partners enjoy the tranquility of knowing that they will deliver projects as contracted and on time.

Future of Outsourcing in Steel Detailing

The steel detailing outsourcing environment is changing very fast. As construction projects are getting more complex, international companies are putting more and more economic jobs to outsourcing companies, which can provide economically viable, technology-oriented solutions. Instrumental to the future is the following:

Integration of AI and Automation

Recurring detailing processes and connection and assembly errors are being automated with Artificial Intelligence (AI) in order to come up with a quick substitute to the possible connections and assemblies. This will also accelerate turnaround time, and human error is minimized.

Growing Role of BIM and Cloud Collaboration

Building information modeling (BIM) has ceased being a choice that requires explanation – it’s establishing itself as a worldwide standard. Outsourced companies are now providing services of BIM-enabled detailing to enable architects, engineers, and contractors to work in real-time on the cloud-based systems. The change enhances coordination and alleviates conflicts on the construction sites.

Increased Reliance on Global Talent Pools

There is more coordination of activities globally than ever before as the firms in the US, UK, and Australia outsource their operations to nations such as Vietnam and the Philippines. Time differences offer a 24/7 workday, thereby providing faster delivery and less time spent being tied down.

Focus on Long-Term Strategic Partnerships

Instead of short-term, one-off projects, companies are now looking for long-term partnerships with outsourcing firms. This builds trust, improves workflow familiarity, and ensures consistent quality across projects.

Sustainable and Green Detailing Practices

As the construction industry moves toward sustainability, outsourced detailing firms are also integrating eco-friendly practices, optimizing designs to reduce material wastage and support green building certifications like LEED.

Conclusion

In conclusion, outsourcing steel detailing services offers construction firms and engineering companies in Hauppauge and across Long Island a smart, cost-effective, and efficient way to handle complex projects. By partnering with specialized professionals who use advanced software and industry expertise, businesses can achieve greater accuracy, faster turnaround times, and notable cost savings. At the same time, outsourcing allows local companies to stay focused on their core operations while minimizing risks and overhead costs.

With the construction industry in New York moving toward higher efficiency and innovation, outsourcing steel detailing has become more than just a cost-saving approach—it is a strategic decision that ensures competitiveness, quality, and long-term success. For firms seeking reliable support, Strand Consulting Corporation, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, offers trusted local expertise. You can reach them at (631) 805-3179 or email connect@strand-co.com.