Steel detailing is a very important part of any construction project. It aids in making sure the steel structures are safe, accurate, and ready for construction. The people are usually worried about the amount of money that they will have to spend.

The price depends on some factors such as the size of the project, the design specification, and the skill of the detailer. The blog will explain what to expect and how to control your budget.

What is Steel Detailing?

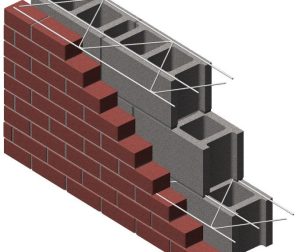

Steel detailing is the process of designing accurate drawings and plans of steel structures. Steel fabricators and builders use these drawings to cut, bend, and fit steel parts properly. Inaccurate detailing may cause construction mistakes, which add to the probability of material errors and increased expenses.

There are two basic types of drawings that Detailers make:

- Shop drawings: These are the drawings used by the fabricators to make the steel components.

- Erection drawings: To enable construction teams to assemble the steel safely and correctly on site.

Why is Steel Detailing Important?

The expenses of steel detailing services might appear to be high; however, these services bring great value to the project. Accurate detailing:

- It avoids construction delays.

- Minimizes wastage of materials.

- Make sure the structure is safe and sound.

- Enhances the interaction among engineers, architects, and builders.

Without detailing, errors may prove costly in the future. Investing in quality detailing service will save you more in the long run.

Factors That Affect the Cost of Steel Detailing

Not all projects have the same cost of steel detailing services. Pricing may vary depending on the kind of structure, its complexity, and the person doing it. To prevent confusion, there are key considerations every detailer uses when providing you with a quote.

1. Project Size and Complexity

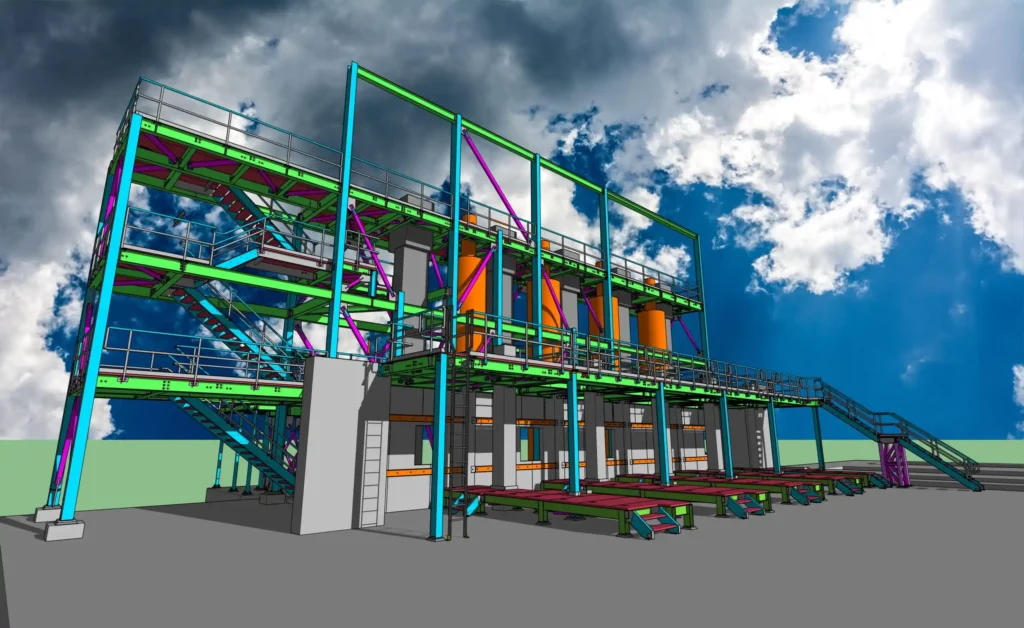

The size of your project greatly contributes to the cost. Larger projects like high-rise towers or industrial plants will obviously take more time, drawings, and detailed planning than smaller structures like residential houses.

Complexity is another major factor. A basic warehouse that is a straight beam, needs simple joint will be less expensive. Projects that have curved beams, multiple stories, need personal joints, or have special architectural designs will be more expensive. In case the structure is unique or complex, the detailer would have to work harder, and this ultimately increases the cost.

2. Level of Detail and Standards Required

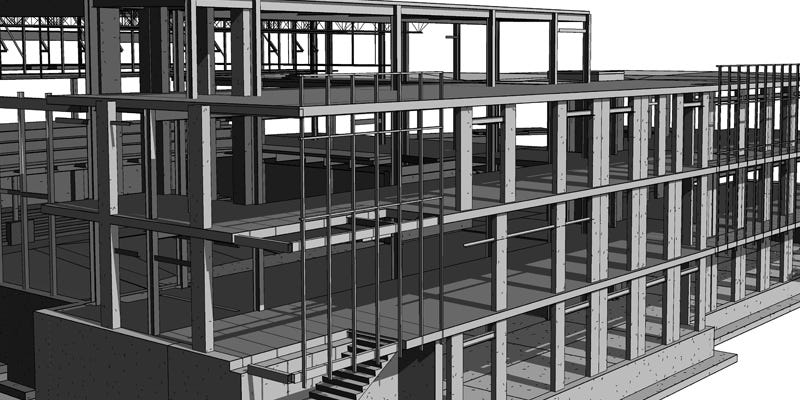

Not every project requires the same detailing. Some need only 2D shop drawings and others need 3D models, complex connections and a great degree of detail. The price increases according to the degree of detail, which consumes time and energy.

The price is also influenced by standards and building codes. Projects with strict safety requirements or international standards (American, European, or Australian codes) are more time-consuming and demand greater expertise. A detailer has to check everything twice to ensure every minor detail is at the right standard, and this comes at a cost.

3. Tools, Software, and Technology

The process of steel detailing is no longer merely about drawing by hand. The majority of professionals are currently working with complex software, such as Tekla Structures, AutoCAD, or Revit, to create correct 3D drawings.

Such tools minimize the number of errors as well as improve coordination among teams, though such tools demand proficient specialists, knowledgeable about their use.

Most projects that involve a higher level of 3D modeling or Building Information Modeling (BIM) will most likely be more expensive than projects that only require simpler 2D shop drawings. The reason is simple: the more the technology is advanced, the greater the skill and time used.

4. Experience and Expertise of the Detailer

Experience of your detailer is a major cost consideration. A skilled and experienced steel detailer will tend to be more costly, yet they will produce more reliable work, and most of it requires fewer corrections. This will save money in the long run since errors and rework in construction are much more costly.

Conversely, an inexperienced detailer might offer a lower price, but flaws in their work can result in a time delay and additional expenses in fabrication or construction. Investing in quality detailing at the initial stage is always a good idea to avoid mistakes in the future.

How Steel Detailing Costs Are Calculated

Various parties can calculate the cost of their services differently. Pricing method generally varies based on the type of project, the needs of the client, and how the detailer wants to work.

Here are the most common ways steel detailing costs are calculated:

- Per Hour: Some detailers work on commission, and most of the work may cost between $20 and $80 per hour, depending on experience and location. This is effective with small projects or unclear scopes, and the overall price can be difficult to estimate as it depends on the number of hours worked.

- Per Ton of Steel: Many detailers price by the ton of steel in the project, frequently at $80 to 150 per ton. Larger or heavier structures need greater numbers of drawings, and thus, this type of method links the size of the project to cost and is familiar to medium to large projects.

- Per Drawing Sheet: Pricing in this approach is based on the quantity of drawings or sheets needed. For example, given that every sheet costs 100, 50 sheets are required in a project, then the cost would be 5000. It is simple and can be expanded in case additional sheets are required in the future.

- Lump Sum (Fixed Price): For well-defined projects, companies may offer one fixed price after reviewing the full scope. This fixed amount will provide clients with a concise initial figure, like 40,000 on a big project, but significant revisions to the project will incur additional fees.

Estimated Pricing You Can Expect.

Prices may vary depending on location and the complexity, but the following is a general guide:

| Project Type | Estimated Cost Range |

| Small Projects (residential or light commercial) | $2,000 – $10,000 |

| Medium Projects (schools, offices, warehouses) | $15,000 – $50,000 |

| Large Projects (industrial plants, high-rise buildings) | $60,000 and above |

Remember, these are estimates. Total cost will depend on your specific needs and the company you opt for.

Why Paying for Quality is Worth It

Steel detailing should not be seen as another expense, but it is also an investment in the success of your own project. Proper detailing ensures that everything fits into position, which reduces time wastage, rework, and safety problems. Investing $5,000 in quality detailing today can save you 50,000 dollars or more on costly mistakes made during construction, so it is not a bad investment in any project.

Conclusion

Steel detailing costs in Hauppauge, NY often depend on the size and complexity of the project, along with the specific details required. Although prices might seem high at first glance, they play a crucial role in making sure your project is safe, accurate, and efficient. By understanding how these costs are calculated and what factors influence them, you can better manage your budget and avoid unexpected expenses.

For businesses and contractors in the Long Island area, working with qualified and experienced detailers ensures that you save time, money, and stress in the long run. If you’re looking for trusted local expertise, you can connect with Strand Consulting Corporation, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788. Call (631) 805-3179, email connect@strand-co.com, or visit their website for more details. You can also find them easily on Google Maps.

FAQs

1. What does a steel detailer do?

A steel detailer prepares accurate drawings and models of steel structures. These drawings guide fabricators in making steel parts and help builders assemble them correctly on site. Their work ensures that structures are safe, strong, and built without costly mistakes.

2. Why do steel detailing costs vary so much?

Costs vary based on project size, design complexity, required details, and deadlines. For example, a small warehouse with simple beams will cost much less to detail than a high-rise building with custom joints, international codes, and tight schedules.

3. Can outsourcing steel detailing save money?

Yes, outsourcing steel detailing to countries with lower labor costs can reduce expenses. However, it’s important to check the company’s experience, quality standards, and ability to follow local building codes to avoid mistakes that might cost more later.

4. Is it worth paying more for an experienced detailer?

Absolutely. An experienced steel detailer may charge more but deliver accurate, efficient, and code-compliant drawings. This reduces errors, rework, and delays. In the long run, paying for quality saves money by preventing construction issues and keeping the project on schedule.