One of the most crucial stages in modern construction is steel detailing. It links the concept of architects and engineers to the real fabrication process. Even the best designs cannot be converted into safe and useful structures without proper detailing.

This is done by making accurate drawings, shop drawings, and erection plans that direct fabricators and builders. From design to fabrication, accuracy, safety, and efficiency are guaranteed in each step. This blog will discuss the complete process of steel detailing.

Importance of Steel Detailing in Construction

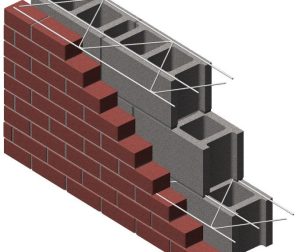

Steel detailing is the process of making detailed drawings and documents that indicate how steel structures will be constructed. Such drawings enable fabricators to get precise metrics, materials, and links to produce steel components. They also lead construction teams in the process of installation.

In short, steel detailing acts as a bridge between design and construction. It converts the concepts of engineers and architects to the proper specifications for fabricators and builders. In the absence of steel detailing, the projects would experience confusion, delays, and expensive errors.

The following are some reasons why steel detailing is so important:

- Accuracy – The slightest errors in measurements may lead to time loss and construction problems.

- Safety – Strong connections and proper placement minimize the risks during construction and post-construction.

- Efficiency – The clear drawings will reduce confusion, allowing construction teams and fabricators to work smoothly.

- Cost Control- Accurate plans save time, money, and eliminate waste materials and rework.

Key Players in the Steel Detailing Process

Only a single individual cannot perform steel detailing- it is a teamwork process. The role of many professionals is significant, and every step is interdependent.

1. Architects

These are the people who imagine the general layout of the building. Architects determine the appearance of the structure, the arrangement, and the style. The project vision is depicted in their drawings.

2. Structural Engineers

As the architects are concerned with appearance, the engineers ensure that the building is strong and secure. They determine loads, stresses, and forces to ensure that the building is capable of sustaining weight, wind, earthquakes, and other stresses.

3. Steel Detailers

Detailers receive information provided by architects and engineers and transform it into highly accurate drawings. They consist of shop drawings for fabricators and erection drawings for builders. They display all bolts, welds, and connecting points, ensuring that nothing has been missed.

4. Fabricators

Fabricators have to use the shop drawings to cut, bend, and weld steel pieces. Their task is to make every detail in the plans of the detailer exactly as it is, so they can all fit together when it is time to assemble.

5.Contractors/Builders

Lastly, the contractors and the builders assemble everything at the site. With the help of erection drawings, they elevate, adjust, and attach the steel members to build the structure in a secure and precise way.

The Step-by-Step Steel Detailing Process

Steel detailing involves a clear set of steps to transition a project into a reality. Each stage builds on the previous one, ensuring accuracy, safety, and smooth progress from drawings to final assembly.

1. Understanding the Design

It starts by reviewing architectural and structural design drawings. The detailer researches the requirements such as loads, materials, and safety codes. The step ensures that the final drawings will be purposeful to the project.

2. Creating Shop Drawings

These detailed plans, called shop drawings, serve to cut, bend, and weld steel by fabricators. These drawings include:

- Dimensions of each steel part

- Type and grade of steel

- Welding and bolting instructions.

- Surface treatments, such as painting or galvanizing

The fabrication depends on shop drawings. Manufacturers cannot make the correct parts without them.

3. Creating Erection Drawings.

Erection drawings represent how the various steel components will be put together at the site. They lead construction teams on:

- Where each part fits

- The sequence of installation

- Safety notes on heavy parts lifting and joining.

Erection drawings reduce misunderstanding in the workplace by eliminating delays during the construction work of a building.

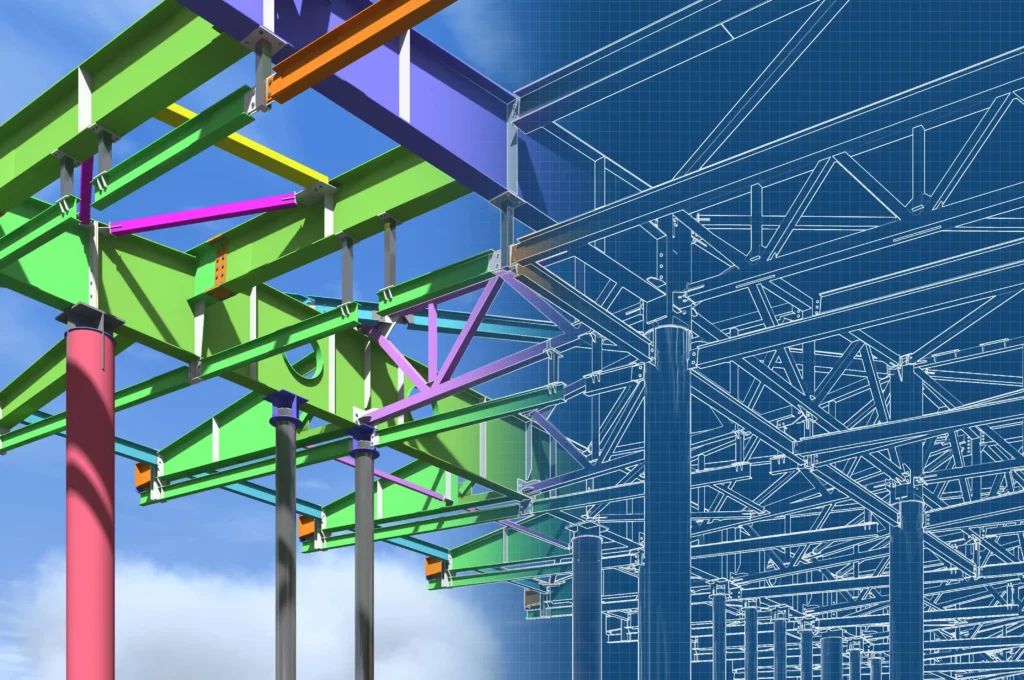

4. Software and Technology Usage

AutoCAD, Tekla Structures, and Revit are modern software that play a crucial role in modern steel detailing. These are used to make 3D models to avoid errors and enhance cooperation. Detection of clashes can also be done with the help of digital models, making sure that the steel parts become perfectly compatible with other systems (such as plumbing and electrical).

5. Reviewing and Approval

Shop and erection drawings are also subject to a review before fabrication begins. They are thoroughly examined by engineers and architects to ensure their accuracy and code compliance. Fabrication can only start after approval.

6. Fabrication

After approving drawings, fabricators start making components of steel. They cut, drilled, and welded the steel based on the specification. Precision at this point is crucial as a single error will potentially impact on assembly at the location.

7. On-Site Assembly

The last step is the joining of the fabricated steel at the construction site. Builders join beams, columns, and trusses to create the structure using erection drawings. Accuracy at this level guarantees that the project is secure, robust, and durable.

Challenges in Steel Detailing

Detailing steel is a challenge despite the advanced tools:

- Complex Structures – Skyscrapers, bridges, and industrial plants tend to have intricate structures, demanding great precision.

- Designing Change – When architects or engineers make changes, detailers will have to make a fast change in drawings.

- Coordination Problems – Steel detailers have to collaborate with other professionals to minimize design conflict.

- Time Pressure – Construction projects are usually on a tight schedule where accuracy and speed are equally important.

Nonetheless, with expert detailers, the transition between design and fabrication goes flawlessly.

Benefits of Professional Steel Detailing

The hiring of experienced steel detailers brings many advantages to a construction project. Their elaborate software and bank checking programs eliminate many errors, which can be very expensive. Detailed drawings also enhance communication amongst the architects, engineers, fabricators, and contractors, so everyone is at the same level.

When projects are well guided, they progress smoothly, are on time, and within budget. Professional detailing also reduces the overall costs of waste and rework of materials. Most importantly, proper detailing ensures the safety codes and standards of the structure are met, and the result is robust and stable.

Conclusion

The unknown strength of every successful steel structure in Hauppauge and across New York is professional steel detailing. It transforms design concepts into practical fabrication and construction instructions. From preparing shop drawings to managing on-site assembly, every step is vital for safety, precision, and efficiency.

With advanced technology, the process of steel detailing has become faster and more secure, helping eliminate errors and reduce costs. Clear communication between architects, engineers, fabricators, and builders ensures that projects are delivered on time and always meet the highest standards.

For expert steel detailing services in New York, you can reach Strand Consulting Corporation at (631) 805-3179, or stop by the office at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA.

FAQs

1. What is the role of a steel detailer?

A steel detailer prepares highly accurate shop drawings and erection plans. These drawings show fabricators how to manufacture steel components and guide builders during installation. Their work ensures the structure is built safely, correctly, and in line with the design.

2. How long does the steel detailing process take?

The timeline depends on project size and complexity. Small projects with fewer parts may take only a few weeks, while larger projects like bridges or industrial plants can take several months to complete properly, ensuring accuracy and safety throughout.

3. What software is used for steel detailing?

Steel detailers commonly use software such as AutoCAD, Tekla Structures, Revit, and Advance Steel. These programs help create 2D and 3D models, improve accuracy, and allow teams to collaborate more effectively, reducing errors during both fabrication and construction stages.

4. Why is steel detailing important in construction?

Steel detailing is important because it ensures precision in fabrication and assembly. With accurate drawings, mistakes are avoided, safety is improved, and construction delays are minimized. It also helps architects, engineers, fabricators, and builders work together more smoothly and efficiently.