The construction of buildings using precast concrete has taken a central position in modern architecture and infrastructure construction due to the speed at which it is constructed, its quality control, and its affordability. Nevertheless, even though it has numerous benefits, the failure or success of any precast project largely relies on accurate and coordinated detailing. One mistake in the shop designs or panel plans may cause delays, risks, and other costs, safety issues or even structural collapse.

This blog will discuss the most frequent precast detailing pitfalls that go wrong time and time again to hamper otherwise well-conceived projects. Structural engineer, detailer, project manager, and quality control supervisor: all should be aware of such risks and how to avoid them to provide high-performing precast systems.

What Is Precast Detailing?

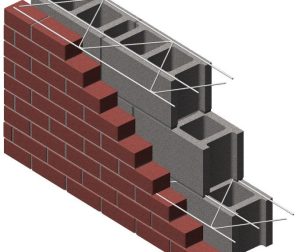

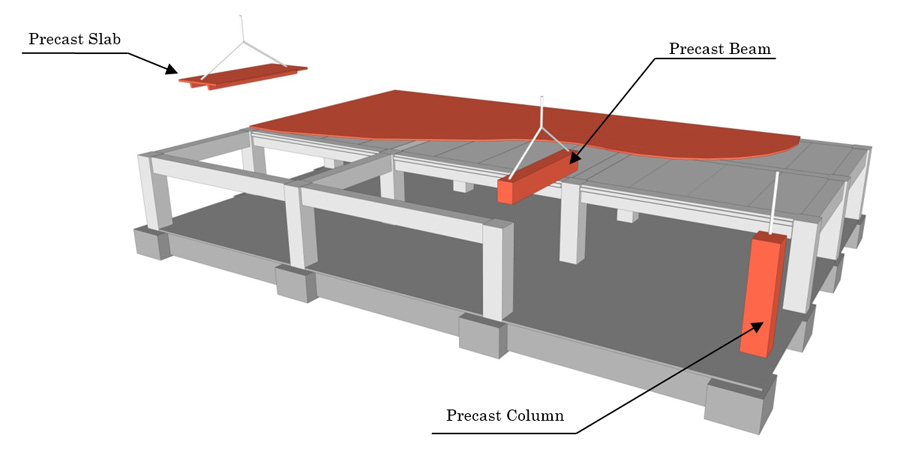

The process involved in converting the structural and architectural designs into shop-level drawings that will help in the fabrication, transportation, and erection of the precast elements is called precast detailing. Such drawings and models tend to specify:

- Precast unit dimensions and tolerances (e.g. walls, slabs, stairs)

- The locations of reinforcement, lifting apparatus, and joints are placed

- Position of embedded items, sleeves, and gaps\ija arador desposuo de coser o protuberancia de los que salen

- Lifting and installation sequence and orientation

When properly done, the precast detailing makes certain that each of the aspects will be cast in place and assembled as it should be to fit at the factory and in the field. However, when not taken seriously or pressed, precast detailing pitfalls begin to crop up. This could result in the lack of embeds, uncoordinated openings, and misaligned panels, which could end up becoming major construction problems.

Why Mistakes in Precast Detailing Are So Critical

Not only are precast detailing pitfalls technical faults, but they can be fatal project liabilities. Malfunctions in a system based upon off-site assembly and just-in-time delivery can make small errors in detailing that can have the ripple effect of creating enormous havoc.

Here’s why accuracy and attention to detail are so critical:

1. High Cost of Errors

A precast panel stamped improperly cannot always be corrected on the job. Contrary to in-situ concrete, precast errors usually necessitate full re-fabrication- resulting in cost rises, wastage of material and even delay in production.

2. Tight Timelines and Sequencing

Erection of precast projects is generally programmed in a strict manner. One misplaced lifting anchor or lost sleeve can halt work on the crane, stop the entire sequence, and affect several subcontractors.

3. Safety Hazards

Through poor positioning of lifting inserts, reinforcement, or support hooks, panel instability may result during lifting or installations, which exposes workers and structures to high-risk conditions.

4. MEP and Structural Conflicts

Problems of poor coordination with other trades are the source of many precast detailing pitfalls. Covering of rebar with ducts or omission of cast-in conduits can affect structural and service performance.

5. Erosion of Client Confidence

The customers demand accuracy in making precast decisions. The repeated problems with detailing indicate an unprofessional approach and may result in arguing relations, broken payments, or legal differences.

Letting these pitfalls of precast detailing get out of control is not simply going to sloppy drawing-it is putting your project, budget, and the reputation of your team in danger.

Common Pitfalls in Precast Detailing

Despite the best effort, details of precast go wrong, quite often a pitfall also occurs when workflows are compressed, there is ineffective coordination or teams are relying on software to the extent they do not have an eye on them. Knowing what these mistakes are is the first step in avoiding them.

A. Incomplete or Ambiguous Drawings

Incomplete drawings that are missing critical data insufficiently, in terms of details, dimensions, section drawings or reinforcement will cause confusion in production and installation. Unless clearly and consistently detailed, it is bound to be misinterpreted.

B. Poor Coordination with Structural and Architectural Models

A failure to coordinate precast drawings with architectural features or structural frames is one of the most underestimated precast detailing perils. Field changes, rework, or the rejection of panels can result when grid lines, window openings, or slab edges are misaligned.

C. Incorrect Rebar Placement and Cover Assumptions

Poor or improper positioning of reinforcement or low concrete cover affects the long-term strength of the structure. Such mistakes are usually caused by copy-paste or the application of old templates.

D. Clash with MEP or Embedded Services

Conflict can be expensive when an electrical conduit or sleeve is overlapped with a rebar cage. When planning between MEP and precast teams is overlooked, many of these conflicts are overlooked.

E. Wrong Lifting and Handling Details

The insert that is lifted too near the edge or in jam-up locations can crack panels or create unsafe erection. This is also one of the most hazardous precast detailing pitfalls, since it directly impacts the safety of the workers and performance of panels.

F. Overlooking Panel Joint Tolerances

Failure to observe correct joint widths and tolerance allowances may cause panel misalignment and water penetration problems. Joints are supposed to accommodate structural poise and fabrication fluctuation.

G. Incorrect Panel Numbering or Sequencing

Redundant or mixed panel labels bewilder the erection teams and logistical groups. Such poorly structured numbering has the potential to stall sequencing, stacking problems, and crane scheduling problems.

Best Practices to Avoid Precast Detailing Mistakes

Avoiding precast detailing pitfalls isn’t just about being careful—it’s about building smart, repeatable systems that catch errors early and streamline coordination. Here’s how to set your project up for success.

A. Establish a Robust QA/QC Process

- Use detailing checklists before issuing drawings

- Schedule internal reviews at 30%, 60%, and 90% completion stages

- Ensure every drawing has section cuts, dimensions, embed callouts, and lifting details clearly labeled

B. Standardize Templates and Detailing Protocols

- Create company-standard templates for panels, joints, and embed symbols

- Use consistent font styles, line weights, and bar notations

- Maintain a central library of reusable details for stairs, lintels, openings, etc.

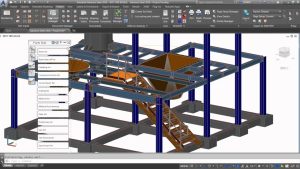

C. Improve BIM and Cross-Disciplinary Coordination

- Hold regular clash detection meetings using Navisworks or BIM 360

- Set up coordination zones for electrical, plumbing, and mechanical pathways

- Use shared models with linked architectural and structural references

D. Account for Handling, Transportation, and Installation

- Simulate lifting and storage sequences in the model

- Design lifter and anchor locations with crane access in mind

- Keep transportation height, width, and turning radius in consideration

E. Collect Feedback from the Field

- Encourage erection crews and QC inspectors to document errors and redlines

- Feed this information back into the detailing process for future improvement

- Use jobsite photography or 3D scans to confirm installation accuracy

Following these best practices not only prevents precast detailing pitfalls but also builds a culture of continuous improvement and collaboration across your precast delivery team.

Tools and Technologies That Can Help

In today’s construction environment, digital tools are essential for reducing precast detailing pitfalls. These technologies not only enhance accuracy but also improve communication, coordination, and productivity across teams.

1. BIM Platforms

- Revit, Tekla Structures, Allplan: These platforms allow for precise 3D modeling of precast components including reinforcement, embeds, and lifting systems. Modeling in 3D helps detect issues early and visualize how each component fits within the overall structure.

- BIM 360 or Trimble Connect: These cloud-based platforms enable teams to collaborate in real-time, reducing delays caused by miscommunication and outdated drawings—two major causes of precast detailing pitfalls.

2. Clash Detection Tools

- Navisworks or Solibri: These tools help identify geometric clashes between precast elements, MEP systems, and structural components before they reach the fabrication stage. Catching issues early avoids costly on-site conflicts.

3. Detailing Plugins and Automations

- Plugins such as Edge reinforcement tools, automatic embed layout generators, and rebar templates help detailers work faster while adhering to standards. When properly configured, these tools significantly reduce repetitive errors and common precast detailing pitfalls.

4. QR Codes and Smart Tracking

- Integrating QR codes into shop drawings and panels allows for field tracking, material handling, and easier coordination between the factory and site teams, minimizing misidentification and sequencing errors.

Conclusion

In Hauppauge, NY, precast construction has become a preferred choice for both commercial and residential projects because it’s faster, more efficient, and offers unmatched quality control—provided the detailing is done right. At our office on Wheeler Road in Hauppauge, we’ve seen how common detailing mistakes—like missed embeds, reinforcement clashes, unclear drawings, and unsafe lifting arrangements—can throw off project schedules, increase costs, and raise safety concerns.

The success of a precast project comes down to how well the detailing connects the design to the real-world build. When you know how to identify and address these detailing hazards early, your projects run smoother, your construction teams work more safely, and your clients are happier.

Whether you’re planning a small local build or a large-scale development in Suffolk County, our team is here to help ensure your precast detailing is done to the highest standard. Visit us at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788 or call (631) 805-3179 to talk about your project.