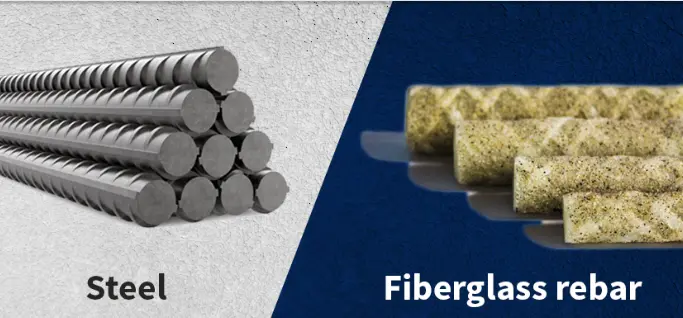

Fiberglass rebar continues to rise as a strong potential alternative to long-established steel rebar in current construction practices. Lightweight and durable corrosion-resistant materials are needed for modern structures, and the comparison between fiberglass rebar and steel helps identify the most suitable option. The analysis takes on great importance due to the current construction trends, which emphasizes sustainability and long-term performance as well as minimized maintenance needs.

This guide provides a thorough examination of fiberglass rebar along with metal rebar for your upcoming project choice decision.

Understanding Rebar: The Backbone of Reinforced Concrete

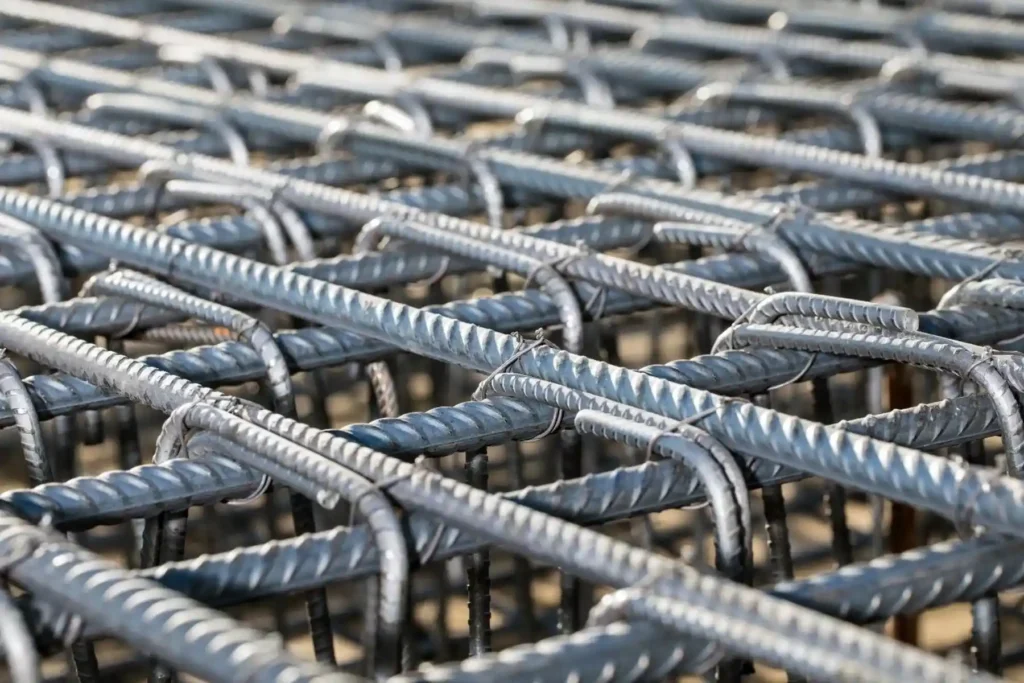

Understanding the application of rebar materials becomes vital before performing material comparisons. Rebar detailing stands as a vital construction element that improves concrete strength under tension. Concrete exhibits high compression strength but shows limited ability to resist being pulled. The use of any combination of steel rebar or fiberglass concrete reinforcement materials protects structures by enabling them to handle different types of weight without damage.

Due to its reliability, economic value, and wide availability, structural modelling and detailing with steel rebar continues to rule the market. The market is witnessing a fast increase in demand for fiberglass rebar, otherwise known as GFRP (Glass Fiber Reinforced Polymer), since it shows non-corrosive properties in water-rich and chemical-heavy settings. Modern materials have been preferred more frequently because users want advanced performance characteristics and reduced maintenance needs.

What is Fiberglass Rebar?

The manufacturing process of fiberglass rebar consists of glass fibers that get embedded throughout a polymer resin, which results in a bar shape that functions much like metal rebar, yet exhibits distinct characteristics. The material features excellent tensile strength alongside exceptional resistance to corrosion, and it remains lightweight at the same time.

The market knows fiber glass rebar as Gator Bars or pink rebar, and manufacturers use it primarily for bridge and steel-corrosive environments and foundations alongside marine installations. Due to its electrically and thermally non-conducting properties, fiberglass becomes a safer material option for selected specialty projects.

The cost of fiberglass rebar at Menards surpasses steel rebar pricing by 1.5 to 2 times per unit. The material delivers important long-term benefits by lowering expenses related to rust and corrosion because of its low maintenance requirements. The low weight of fiberglass allows for swift installation, thus cutting down both time and labor expenses with the help of 2D rebar services.

The application of fiberglass rebar in concrete systems through glass fiber reinforcement delivers superior lifetime performance when exposed to demanding environments. Bordering industries recognize fiberglass as a vital component in sustainable reinforcement systems, often verified through as-built drawings to ensure accuracy and quality.

Pros and Cons of Steel Rebar

The use of steel rebar exists as the primary choice within this sector. Many engineers, together with construction workers and builders throughout the glob,e adopt this technique because it has multiple successful applications.

Pros:

- High availability and relatively low cost.

- Well-established performance history across all construction types.

- The material provides easy cut and bend capabilities so contractors can adapt it to their scheduling requirements.

- The high tensile strength and excellent ductility suitable for regions with heavy loads

Cons:

- Prone to corrosion, especially in coastal or chemical-rich environments.

- Heavier than fiberglass rebar, making it harder to transport and handle.

- Conducts electricity and heat, which may be a disadvantage in sensitive areas.

- Requires more frequent maintenance and inspection in corrosive zones.

Due to its ductility characteristic, steel rebar survives seismic events by arcing like a strong elastic during such events to avoid destructive collapses.

Most construction projects choose steel rebar for concrete reinforcement because it remains the conventional choice thanks to its easily accessible and familiar nature. The material is best suited for building professionals who require consistent materials that behave predictably.

Pros and Cons of Fiberglass Rebar

Fiberglass rebar has gained momentum in construction because of its distinctive features that enter the market relatively recently.

Pros:

- 100% corrosion-resistant

- Up to 75% lighter than metal rebar

- Greater tensile strength in some conditions compared to traditional steel.

- Does not conduct electricity or heat.

- Ideal for glass fiber reinforced concrete applications.

- Resistant to chloride ions, salt, and chemical attacks.

Cons:

- Higher upfront cost per unit.

- Less ductile, not as flexible as steel rebar under stress.

- Limited familiarity that may require specialized installation.

- Cannot be bent on-site like area steel rebar.

- Design codes and acceptance vary depending on the region and the project.

The use of fiberglass rebar in coastal bridges represents a clear example since it results in negligible corrosion maintenance during 20-30 years.

The needs of particular projects, such as bridge decks and seawalls and wastewater plants, and chemical facilitie,s can be best met through fiberglass rebar which demonstrates higher cost efficiency resulting from reduced maintenance requirements in the long term.

Comparing Performance: What’s Stronger, Metal or Fiberglass?

The age-old question: what’s stronger, metal on concrete or fiberglass? The evaluation of strength relies on the particular application with the specific strength parameter assessment, often enhanced through advanced BIM coordination services.

Regarding tensile strength, fiberglass rebar 3D modeling demonstrates equal strength or higher strength than steel rebar. The tensile strength of fiberglass choices at 150,000 psi surpasses standard steel rebar at 60,000 psi.

The strength of steel rebar exceeds its yield limits while demonstrating better flexibility properties. Resistance to breaking through deformation is vitally important in seismic areas because this property allows rebar to absorb earthquake energy. Under such conditions, fiberglass tends to perform poorly because of its brittleness.

The superiority of metal rebar for dynamic and high-impact loading applications wins over fiberglass rebar despite its advantages in corrosive environments and long-term durability.

Application Suitability: Where Each Rebar Works Best

When choosing between fiberglass rebar and steel rebar, understanding the specific application environment is crucial. Each type of reinforcement offers unique properties that make it more suitable for certain structural conditions, project types, and long-term performance goals. Below is a breakdown of where each rebar performs best and why the right choice can have a major impact on safety, durability, and cost-efficiency.

Steel Rebar: The Industry Standard for Conventional Construction

Steel rebar continues to dominate in traditional building projects due to its strength, ductility, and flexibility on-site. Here’s where it’s most commonly used:

- Residential and Commercial Buildings: From homes to high-rises, steel rebar is ideal for standard reinforced concrete structures such as footings, slabs, beams, and columns. Its ability to bend and cut on-site makes it perfect for adjusting to real-time construction conditions.

- Seismic Zones: One of the most notable advantages of steel rebar is its ductility, which allows it to absorb and redistribute stress during earthquakes. This makes it the preferred reinforcement material in seismic-prone areas.

- Heavy-Load Structures: Due to its strength and load-bearing capacity, steel is often used in structures with dynamic and heavy loading—such as industrial facilities, bridges, and large-scale foundations.

- Cost-Conscious Projects: Rebar Menards and similar suppliers offer area steel rebar at accessible prices, making steel a go-to choice when budget constraints are a primary concern.

Steel rebar is familiar to contractors and structural engineers alike, making it the default choice in many codes and specifications. For environments where corrosion isn’t a pressing issue, it provides a reliable and time-tested solution.

Fiberglass Rebar: A Smart Alternative for Harsh Environments

Fiberglass rebar, or fiber glass rebar, is increasingly used in applications where corrosion, chemical exposure, and electrical conductivity are significant concerns. It excels in the following use cases:

Marine and Coastal Structures: Seawalls, piers, and docks are continuously exposed to saltwater, which can rapidly degrade metal rebar. Fiberglass rebar is completely corrosion-resistant, making it the best option for such environments, as emphasized in advanced BIM consulting services.

Chemical and Wastewater Facilities: Chemical exposure and high pH environments can eat away at traditional steel. In such cases, BIM consulting and fiberglass concrete reinforcement ensure long-term structural integrity without the need for costly maintenance.

Roads, Bridges, and Parking Decks: De-icing salts and moisture are notorious for corroding steel rebar. DOTs are now increasingly turning to glass fiber reinforced concrete with Gator Bars or pink rebar to reduce maintenance and extend service life.

MRI Rooms and Power Plants: Because fiber glass rebar is non-conductive, it doesn’t interfere with sensitive electronics or electromagnetic equipment. This makes it ideal for hospitals, laboratories, and energy generation facilities.

Lightweight and Fast Construction: Being 75% lighter than steel, fiberglass rebar can significantly reduce handling time and labor costs. It’s a smart choice for remote projects or structures with accessibility issues where heavy lifting is not feasible.

While the initial cost of fiberglass rebar may be higher, the savings in maintenance, labor, and longevity often offset this investment, making it a forward-thinking choice backed by industry leaders like Strand Consulting Corporation..

Choosing the Right Rebar: Key Considerations

When determining whether to go with steel or fiberglass rebar, consider these critical factors:

- Corrosion Risk: Go with fiberglass when the corrosion risk is high; otherwise, steel may be sufficient.

- Load Requirements: Heavy and dynamic loads favor steel. For stable and chemical-prone environments, fiberglass excels.

- Project Duration & Maintenance: Long-term infrastructure benefits more from fiberglass due to its minimal upkeep.

- Code Compliance: Some regions or structural designs may mandate steel unless alternative materials are pre-approved.

- Budget vs Lifecycle Cost: Steel wins in upfront costs. Fiberglass wins in life-cycle savings.

Ultimately, the best approach is to assess the project’s environment, durability expectations, and future maintenance budgets. For many modern structural building applications, a hybrid approach, using both types of rebar can offer optimal results.

Final Verdict: Fiberglass Rebar vs Steel

When comparing fiberglass rebar vs steel, it’s not about choosing a universal winner—it’s about selecting the right tool for the job.

If your goal is to build a low-maintenance, corrosion-resistant, and longer-lasting structural building, fiberglass rebar is an excellent option. It helps reduce long-term operational costs and is perfect for infrastructure that demands durability.

On the other hand, if budget constraints and widespread contractor familiarity are top priorities, steel rebar remains a solid and safe choice. The global construction industry has built its foundations on steel rebar for decades.

As construction technology evolves, we may see glass fiber reinforced concrete and fiber glass rebar becoming more mainstream, shifting the balance further in favor of corrosion-free reinforcement solutions.