The current construction environment has never given more emphasis to budgets, schedules, risk reduction, and long-term value by project owners. With the increasing economic strain and the complexity of more and more construction, the trend is shifting to digital transformation as companies seek to remain competitive.

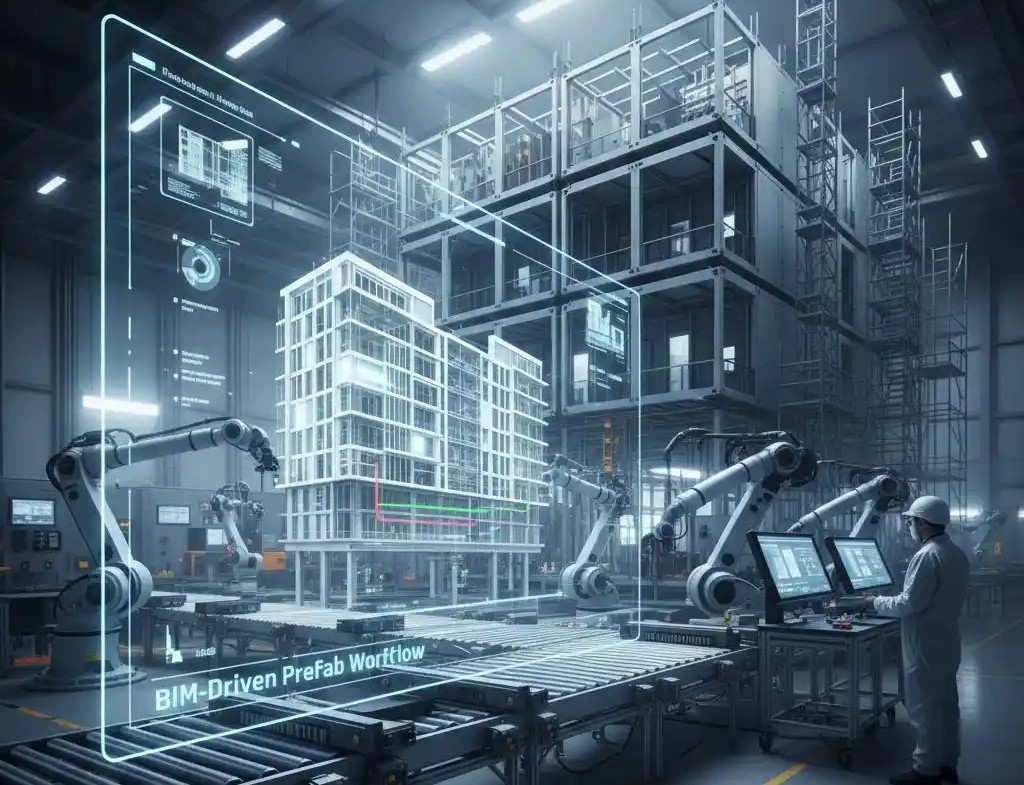

Among the most effective and, at the same time, financially influential methods that have arisen due to this change is the workflow of prefabrication that is based on the BIM. When Building Information Modeling is closely combined with the fabrication process, the contractors will get access to unprecedented accuracy, predictability, and efficiency of operations.

To address these questions, this article will make a detailed analysis of the financial ROI of a BIM-driven workflow based on prefab. We find out why, through an investigation of modeling accuracy and terminated construction schedules, prefabrication under the spur of BIM has been a bulwark of lucrative building.

Why Prefabrication Matters and Why BIM Makes It Work

Prefabrication itself is not new. Contractors have, over the decades, been using off-site fabrication to facilitate the work of installation and minimize the labor on-site. Nevertheless, the conventional prefabrication is also usually limited in some ways: inaccurate measurements, lack of coordination, absence of dimensions, or unanticipated interfaces, which are only revealed on-site when the materials are delivered. These problems are reflected in adaptation, time wastage, and, eventually, wastage of money.

It is at this point that BIM comes in to ruin the equation. A BIM-based prefab workflow will make sure that components are designed with the level of fabrication detail, coordination between disciplines, and will be tested prior to production. Systems such as mechanical ductwork, electrical raceways, plumbing risers, and multi-trade corridor racks can be built out of an integrated model, and then the entire process is much more predictable.

This change has a financial implication that is hard to overestimate. BIM reverses the current approach of reactive prefabrication into a proactive one- that reduces risk, costs, and increases productivity on a large scale.

Reducing Rework: The Fastest Route to ROI

One of the biggest hidden construction costs is rework. According to studies conducted by the Construction Industry Institute, rework costs 5%-15% of the overall cost of a project, and a large proportion of this rework is a result of design or coordination problems. A prefab workflow that is powered by BIM addresses rework on several levels.

Since the components are modeled using a high level of detail, which is typically LOD 350 to LOD 400, the components can have the dimensional detail to be executed precisely. This gets rid of guesswork and minimizes the chances of making mistakes during installation.

Historically, the appearance of mismatches between drawings and the reality situation in a traditional working process often causes teams to repeat the design, create new components, or redesign some part of a system. By comparison, prefab, with the assistance of BIM, will only see the contractors construct what is completely coordinated and confirmed.

Material Savings Through Data-Driven Precision

Material waste is another significant financial drain in conventional construction. Sometimes, when systems are cut or put together at the job site, errors are likely to occur, and the result is scrap, unused material, or wrong orders. Prefabrication using the power of BIM allows orders to be created according to exact measurements obtained in the Precast Panel model.

This applies specifically to electrical trades, where lengths of conduit and cable can be measured precisely before fabrication, and hence the amount of material wastage is kept to a minimum. The same applies to even ductwork, which has generally been a wasteful endeavor because of the difficulty in cutting the work on site, but there is an added advantage to the fact that the fabrication-ready BIM Modeling Services model has very specific dimensions.In the long run, the contractors that are dependent on the BIM-based material orders are regularly seen to experience less waste and a more sporadic purchasing plan,

which enhances the overall profitability of the project.

Labor Efficiency: Making Skilled Workers More Valuable

One of the most expensive elements of construction is labor, and the labor shortage that occurs is worsening the situation. A prefab workflow with BIM can be strongly applied to increase labor productivity by transferring work from the unpredictable site conditions to the controlled fabrication facilities.

The employees in the shop enjoy predictable environments, specialized equipment, layouts, and processes. This reduces errors as well as enables the teams to finish installations at a faster rate. The productivity is further boosted by manufacturing multi-trade assemblies simultaneously, which enables a number of systems to be installed simultaneously using fewer workers.

When the target of field teams is on installation and not fabrication, the skilled labor is applied more strategically. This redistribution enables the contractors to get more done with more efficient teams to reduce overtime, minimize labor expenses, and enhance the overall project schedules.

As a result, contractors see tangible ROI through:

- Reduced field labor hours

- Fewer specialized workers on-site

- Improved installation speeds

- Lower overtime expenditure

- Fewer delays tied to manpower shortages

In essence, BIM-driven prefabrication converts labor from a reactive cost center into a structured, high-efficiency asset.

Better Scheduling and Predictable Timelines

Delays are among the costliest risks in construction. Renting equipment, waiting time for labor, fines, and interruptions in logistics all multiply throughout. Prefabrication through BIM leads to tremendous predictability in terms of scheduling.

The projects move forward more efficiently when there is a delivery of prefabricated elements to the workplace, where all that is required is to install. With the fabrication schedules directly related to the BIM model, teams have the ability to plan better, order materials sooner, and have the deliveries in line with the installation schedule. Such control minimizes the downtime and makes sure that trades do their work efficiently without affecting the other trades.

This dependability is particularly important in large-scale or hurried projects in which disruptions are felt even the smallest disruption is felt. Prefabrication saves time on the construction step and provides the contractors with the courage to pursue aggressive scheduling, which is usually an aperture to novel prospects and competitive edges.

Risk Reduction: A Financial Benefit Often Overlooked

Risk management has an enormous financial impact. Every construction project faces uncertainties, weather conditions, labor shortages, safety incidents, and design changes. BIM-driven prefabrication reduces these risks in several ways:

- Reduced site exposure: Less work on site means fewer workers exposed to harsh environments, leading to improved safety outcomes and lower insurance costs.

- Improved predictability: A digital model reveals issues early, reducing the risk of late-stage disruptions.

- Enhanced logistics: Prefabricated components arrive when needed, reducing the risk of loss, damage, or storage complications.

- Safer installation processes: Controlled shop environments minimize injuries, translating into fewer claims and lower premiums.

Because financial ROI isn’t just about earning more, it’s also about safeguarding the budget, BIM-driven prefab gives contractors a powerful tool for reducing liabilities and protecting profit margins.

Real-Time Visibility and Decision-Making

One of the biggest advantages of BIM-integrated prefabrication is the visibility it provides. When teams have real-time access to the BIM model, they can monitor progress, identify bottlenecks, and evaluate construction impacts before decisions are made.

This visibility allows contractors to anticipate challenges and adjust plans proactively rather than responding to issues as they arise. Decision-makers can evaluate multiple design scenarios, estimate cost variations, and select paths that optimize both performance and budget.

Owners also benefit from clearer projections and more accurate forecasts, making it easier to manage expectations and avoid disputes. Transparency builds trust, and trust reduces costly conflict.

Scaling Prefabrication for Greater Financial Impact

The ROI of a BIM-driven prefab workflow increases dramatically as a contractor scales the process across multiple trades or projects. When prefabrication becomes a standard practice, firms benefit from:

- Economies of scale

- Repeatable workflows

- Standardized assemblies

- Optimized shop layouts

- Faster model development

- Improved trade coordination

Eventually, companies can develop multi-trade prefabrication strategies, assembling electrical, mechanical, plumbing, and fire protection systems into integrated racks or pods. These assemblies can be replicated across floors or zones, drastically reducing installation time and labor requirements.

Contractors who invest early in BIM-driven prefabrication often find that their capabilities become a key differentiator, helping them win more bids, close more contracts, and build long-term relationships with clients.

Long-Term ROI Beyond a Single Project

A BIM-driven prefab workflow generates long-term financial returns beyond immediate savings. Companies that adopt this approach gain advantages that compound over time, including.

- Reusable modeling standards that accelerate design

- Higher win rates due to enhanced capabilities

- Reduced overhead through more predictable workflows

- Data-driven insights that improve future project performance

- Stronger client relationships built on transparency and reliability

The more a company uses BIM-driven prefabrication, the more efficient it becomes and the more its profit margins improve.

Conclusion

The financial ROI of a BIM-driven prefabrication workflow is clear for construction firms across Hauppauge and the greater Long Island area. By reducing rework, minimizing material waste, improving labor efficiency, speeding up project timelines, and lowering overall risk, this approach helps local contractors protect margins on increasingly complex builds. Contractors who work with STRAND Consulting are not just adopting new technology but gaining a strategic advantage that directly improves profitability and competitive positioning. Based at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, STRAND Consulting supports regional construction teams with scalable BIM-enabled prefabrication solutions designed for today’s demanding building requirements. For guidance, teams can call (631) 805-3179 or visit their Google Maps location. As construction timelines and compliance standards continue to tighten across New York, BIM-driven prefabrication has become the most reliable and cost-effective path forward for local building teams.