Concrete Masonry Units (CMUs) are one of the pillars of contemporary construction and are considered to be durable, versatile, and cost-effective. Nevertheless, it is not the block that makes a CMU wall strong its strength is the ability to correctly design and implement an effective reinforcement. The determination of reinforcement size, concrete cover and the choice of units have a direct influence on the structural performance, service life and code compliance.

This is a complete instruction manual of CMU cell reinforcement whereby we will discuss everything to know about CMU cell reinforcement such as selecting the correct bar size, giving it proper cover, and selecting appropriate CMU units against various conditions encountered in the structure.

Understanding CMU Cell Reinforcement

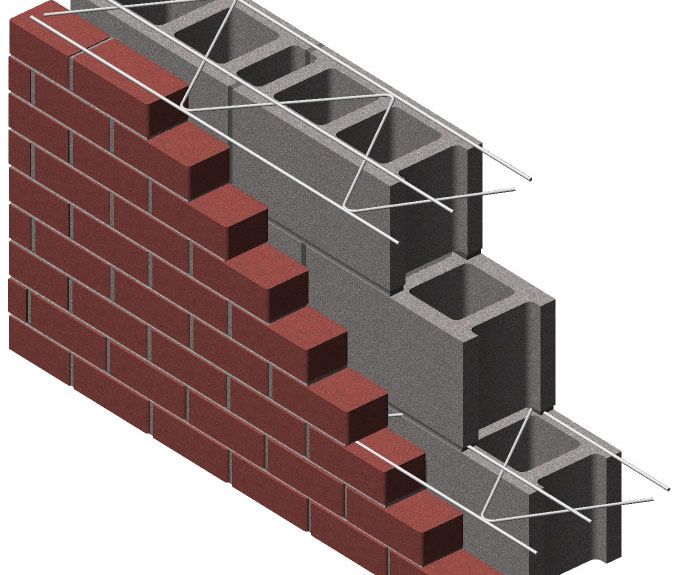

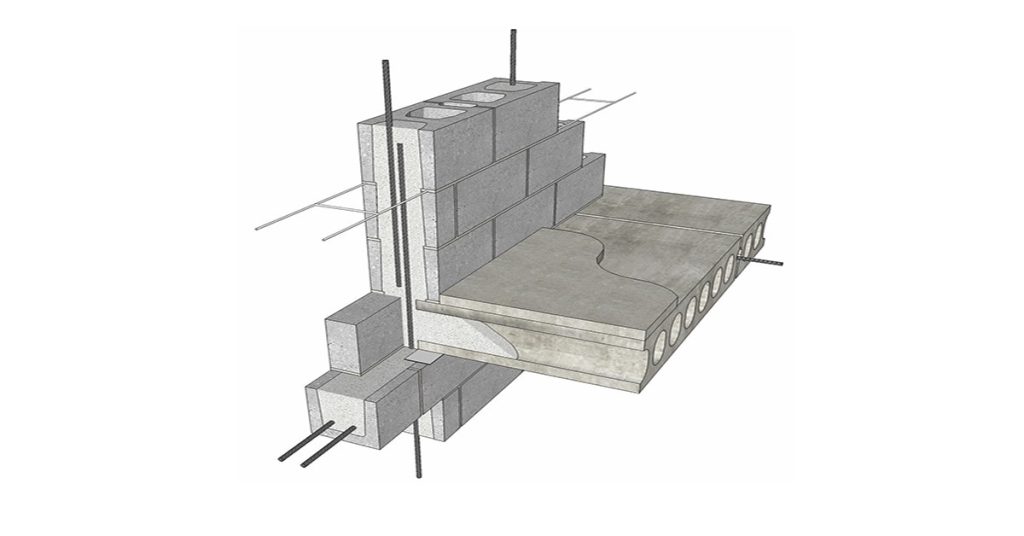

In CMU cell reinforcement, steel reinforcement bars (rebar) are either vertically or horizontally placed in hollow cells of units of masonry and then grouted. With this combination, these masonry walls can resist:

- Axial loads from gravity

- Lateral loads from wind or seismic forces

- Bending and shear stresses

- Cracking due to shrinkage or temperature changes

Reinforced CMU construction bridges the gap between plain masonry and reinforced concrete, offering a balanced system that is strong, economical, and adaptable.

Why Proper Reinforcement Matters

Improper reinforcement design is one of the most common causes of masonry failure. Undersized bars, insufficient cover, or incompatible unit selection can lead to:

- Reduced load‑carrying capacity

- Accelerated corrosion of reinforcement

- Cracking and spalling of masonry

- Premature structural deterioration

- Non‑compliance with building codes

Proper CMU cell reinforcement ensures that the wall performs as intended throughout its design life, often 50 years or more.

Reinforcement Size: Choosing the Right Rebar

One of the most important choices in reinforced CMU construction is the choice of the appropriate reinforcement size. The magnitude of the rebar will have a direct impact on the capacity of the wall to withstand the axial forces, bending forces and the lateral forces like the wind or earthquake. Selecting a bar that is excessively small may affect structural capacity whereas excessively large reinforcement can cause problems with placement, inhibit the flow of grout, and limit the necessary concrete cover.

Common Rebar Sizes Used in CMU Walls

Reinforced masonry walls typically use deformed steel bars ranging from #3 to #6, depending on structural demand and unit size:

- #3 rebar (3/8 in or 10 mm): Used in lightly loaded walls, non-load-bearing partitions, or low-height masonry elements.

- #4 rebar (1/2 in or 13 mm): The most commonly used size for standard reinforced CMU walls, balancing strength and constructability.

- #5 rebar (5/8 in or 16 mm): Suitable for load-bearing walls, taller wall sections, and moderate seismic or wind zones.

- #6 rebar (3/4 in or 19 mm): Typically reserved for heavily loaded structural walls, shear walls, and high-seismic applications.

The selected bar must fit comfortably within the CMU cell while allowing space for grout consolidation and maintaining minimum cover requirements.

Factors Influencing Rebar Size Selection

The choice of the rebar size depends on several important factors, and each of them is important to guarantee that the masonry wall will be safe, efficient, and building codes compliant. The knowledge of these factors assists designers and constructors to choose reinforcement that will provide the desired strength without affecting placement, life, or performance.

Structural Loading Requirements

Walls supporting higher gravity loads or resisting significant lateral forces require larger-diameter reinforcement. Load-bearing and shear walls commonly demand #5 or larger bars, especially in multi-story construction.

Wall Height and Slenderness Ratio

The higher the wall height the greater the bending stress due to lateral loads. The use of taller and thinner walls would necessitate either a larger rebar size or less spacing, to manage deflection and cracking.

Reinforcement Spacing

Rebar size and spacing work together. Wider spacing typically requires larger bars to achieve the same structural capacity, while closer spacing may allow for smaller bars. Designers must balance performance with constructability and cost.

CMU Cell Dimensions

The maximum rebar diameter is dependent on the internal cell size of CMU. Placing bigger bars in the smaller cells may minimize the grout coverage, leave spaces, and breach minimum cover. The size of a unit selection and reinforcement should be constantly synchronized.

Constructability and Placement Considerations

Proper placement is just as important as bar size. Reinforcement should be centered within the CMU cell to ensure uniform grout cover on all sides. Rebar positioners or spacers are commonly used to prevent bars from touching the block webs or faceshells.

Oversized bars can also interfere with lap splices, mechanical couplers, and grout placement. Selecting a practical rebar size improves installation efficiency and reduces the risk of field errors.

Concrete Cover: Protecting the Reinforcement

Concrete cover is a critical protective layer that shields reinforcing steel from environmental exposure and mechanical damage within a CMU wall. It plays a vital role in preventing corrosion, maintaining bond strength between steel and grout, and enhancing fire resistance.

What Is Concrete Cover?

Concrete cover refers to the minimum distance between the outer surface of the reinforcement and the masonry or grout surface. Adequate cover is essential to:

- Protect steel from corrosion

- Provide fire resistance

- Ensure proper bond between steel and grout

Code‑Recommended Cover Requirements

While exact requirements vary by code and exposure conditions, typical minimum covers include:

- Interior, dry conditions: 1/2 to 3/4 inch

- Exterior walls: 1 to 1‑1/2 inches

- Walls exposed to earth or weather: Up to 2 inches

Always refer to the applicable building code (such as TMS 402/602 or local standards) for precise requirements.

Why Cover Is Critical

Insufficient cover exposes reinforcement to moisture, chlorides, and carbonation, leading to corrosion. As steel rusts, it expands, causing cracking and spalling of the masonry. Proper cover significantly extends the service life of CMU walls.

CMU Unit Selection: Matching Units to Reinforcement

Selecting the right CMU unit is just as important as choosing the correct reinforcement size. The internal geometry of the block, cell width, web thickness, and faceshell dimensions, directly affects how reinforcement is placed, how much concrete cover can be achieved, and how effectively grout consolidates around the steel. Poor coordination between CMU units and reinforcement often leads to congestion, inadequate cover, and long-term durability issues.

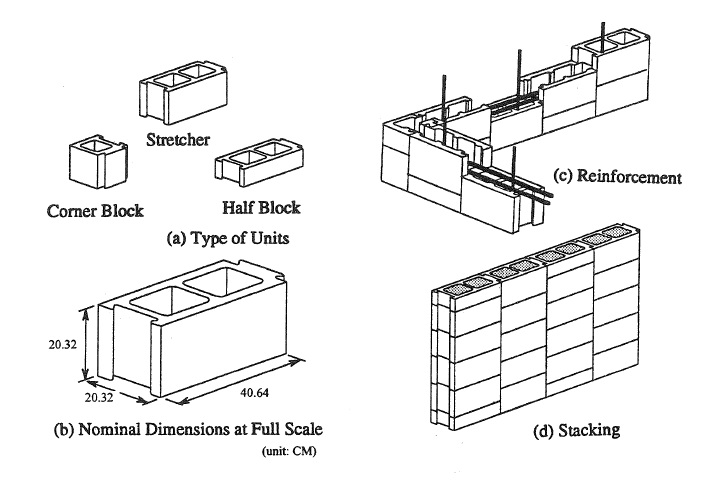

Standard CMU Sizes

Choosing the correct unit size ensures that the specified rebar fits comfortably within the cell while meeting minimum cover requirements and allowing proper grout placement.

CMUs are available in several nominal sizes, with the most common being:

- 8 × 8 × 16 inches

- 10 × 8 × 16 inches

- 12 × 8 × 16 inches

Larger units generally allow for larger reinforcement and more grout, increasing load‑carrying capacity.

Cell Geometry and Rebar Fit

Not all CMUs are created equal. Cell size, shape, and web thickness affect reinforcement placement.

Key considerations include:

- Ability to place the specified bar size with required cover

- Adequate space for grout consolidation

- Compatibility with mechanical couplers or lap splices

Open‑End and Bond Beam Units

- Open‑end CMUs simplify vertical reinforcement placement and grouting.

- Bond beam units accommodate horizontal reinforcement and distribute loads more evenly across the wall.

Selecting the correct unit type improves constructability and structural performance.

Vertical vs. Horizontal Reinforcement

Reinforced CMU walls rely on both vertical and horizontal reinforcement to achieve strength, stability, and durability. Each type of reinforcement serves a distinct structural purpose, and understanding their roles helps ensure that masonry walls can safely resist gravity loads, lateral forces, and cracking over time. A well-designed CMU system typically uses a combination of both to create a balanced and resilient structure.

Vertical Reinforcement

Vertical reinforcement is primarily responsible for resisting axial loads and bending stresses in CMU walls. These bars run continuously from the foundation to the top of the wall and are usually placed within grouted cells at regular spacing.

Key functions of vertical reinforcement include:

- Supporting gravity loads from floors and roofs

- Resisting out-of-plane bending caused by wind or seismic forces

- Improving wall stability and reducing the risk of overturning

- Enhancing load transfer between the wall and foundation

Vertical rebar spacing commonly ranges from 16 to 48 inches on center, depending on wall height, loading conditions, and code requirements. Taller or heavily loaded walls often require larger bar sizes or closer spacing.

Final Thoughts

CMU cell reinforcement is not just a technical detail—it is a critical component of masonry performance in Hauppauge, NY. By carefully selecting rebar size, ensuring adequate cover, and choosing the right CMU units, engineers, contractors, and building owners can create masonry walls that are strong, durable, and fully compliant with building codes. Thoughtful reinforcement design, combined with proper construction practices, ensures that CMU structures safely support loads, resist environmental forces, and deliver long-term value. For expert guidance on CMU reinforcement and superior masonry solutions in Hauppauge, contact STRAND Consulting at (631) 805-3179 or visit their office at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA, or online at Strand Consulting and find directions here.