Modern construction is no longer just about brick and mortar it’s about harnessing innovative technologies to create safer, more efficient, and cost-effective projects. One of the most impactful advancements today is 3D rebar detailing, a process that revolutionizes how professionals plan, visualize, and execute reinforced concrete work. Below, we’ll dive into how 3D rebar detailing works, why it matters, and how it’s reshaping the future of the entire construction industry.

The New Blueprint: 3D Rebar Detailing

What Exactly is 3D Rebar Detailing?

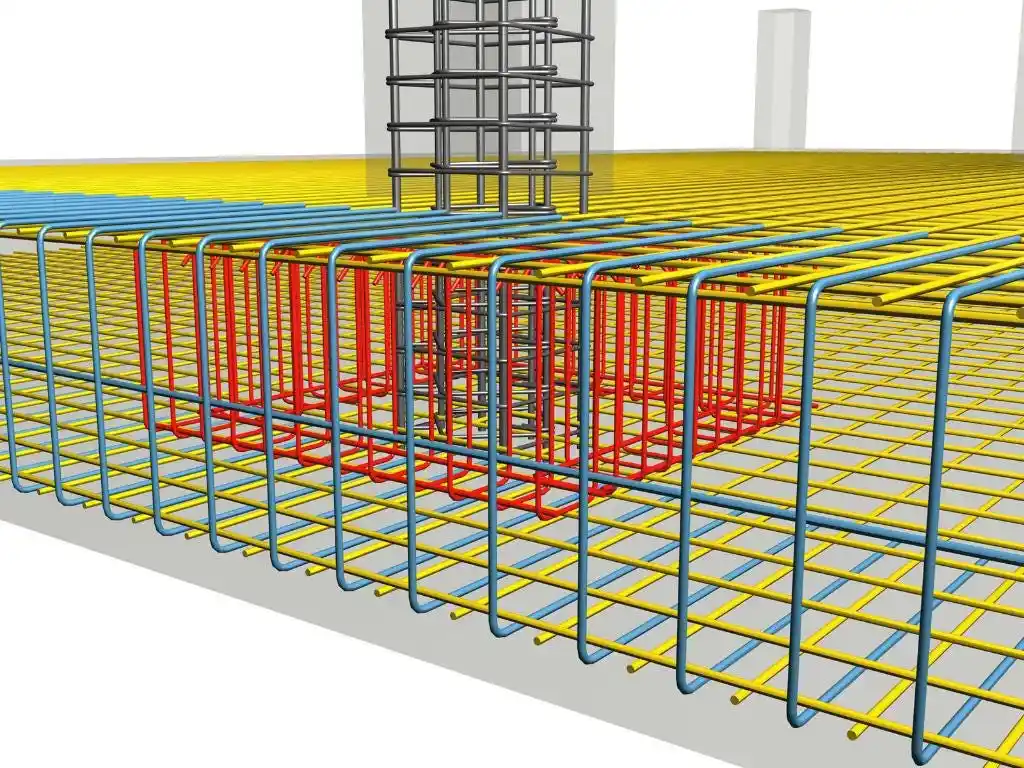

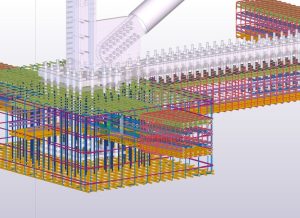

3D rebar detailing is the process of creating precise, data-rich models that illustrate the placement of steel reinforcement (rebar) within concrete structures. By moving away from flat, two-dimensional drawings, project teams gain a clear, highly detailed overview of how various elements intersect and interact. This leads to:

- Reduced miscalculations, thanks to digital precision

- Seamless coordination, as all stakeholders reference the same model

- Improved project timelines, since potential conflicts are caught early

If you’re looking to incorporate these types of high-precision methods into your next project, consider exploring ou Rebar Detailing offerings for an in-depth view of how digital rebar planning can streamline your workflow.

A Glimpse into Its Evolution

Before the rise of 3D modeling, rebar detailing involved time-consuming, often error-prone hand-drawn sketches or basic 2D CAD plans. As Building Information Modeling (BIM) tools gained traction, so did 3D rebar detailing—paving the way for more collaborative, accurate design processes. Today, many construction professionals also leverage specialized BIM consulting to ensure every phase of the project stays aligned with modern best practices and technology standards.

Key Terms & Concepts

- BIM (Building Information Modeling): A holistic digital approach to managing all aspects of a building’s design and construction.

- Clash Detection: Automatic detection of overlapping or conflicting elements within a 3D model.

- Parametric Modeling: A system that updates the entire model instantly when any single component changes.

For more on how BIM integrates with every facet of a project, including coordination workflows, you can learn about our BIM Consulting & Coordination Solutions.

Beyond Flat Drawings: The Leap from 2D to 3D

The Limitations of Traditional 2D Detailing

While 2D drawings have long been the industry norm, they often fall short in complexity and clarity. It’s difficult to:

- Anticipate clashes between rebar and other structural components

- Visualize three-dimensional space, leading to misinterpretations on-site

- Estimate material requirements precisely, which can balloon costs

Transitioning to Dynamic 3D Models

Adopting 3D rebar detailing starts with selecting the right software tools like Autodesk Revit and Tekla Structures are popular choices. These platforms offer interactive features such as automated bar bending schedules, integrated material take-offs, and real-time clash detection. Our BIM Consulting Services can assist in mapping out a successful transition, ensuring your team is trained and equipped to maximize these tools.

Reimagining the Construction Process

With 3D rebar detailing in place, the construction workflow evolves significantly:

- Pre-fabrication becomes smoother due to accurate bar lists and bending details

- Reduced on-site confusion, as everyone references the same integrated model

- Optimized sequencing, cutting down delays and unnecessary rework

Precision in Action: The Benefits of 3D Detailing

Enhanced Accuracy and Error Reduction

3D detailing drastically reduces costly mistakes by showing exactly how rebars intersect and fit within the concrete. This heightened accuracy:

- Decreases waste, as materials are cut and bent precisely

- Shortens timelines, because crews encounter fewer surprises

- Lowers labor costs, minimizing the risk of rework

Boosting Collaboration and Communication

When all project stakeholders from engineers and architects to contractors access a shared 3D model, clarity becomes the norm. By eliminating guesswork, teams can discuss solutions in real time, accelerating decision-making and fostering a collaborative environment.

Real-World Success Stories

Across the industry, companies that have embraced 3D rebar detailing report:

- Significant drops in material overages

- Smoother project coordination, especially during tight deadlines

- Better forecasting, with more accurate scheduling and budgeting

Inside the Engine: The Technology Behind the Software

Exploring Innovative Software Capabilities

Leading platforms like Revit and Tekla offer robust features tailored to rebar detailing, such as:

- Parametric modeling, automatically updating all related design elements when changes occur

- Automatic bar schedules for quick and accurate take-offs

- Clash detection with structural, mechanical, and plumbing elements

To see how these tools are applied in practice, check out our Revit BIM Modeling or learn about our experience with Tekla BIM Modeling solutions.

Integrating BIM for a Seamless Workflow

By pairing 3D rebar detailing with BIM Consulting, companies ensure that their data remains consistent and centralized, from the earliest design stages to final handover. This synergy:

- Eliminates data silos, ensuring every department works from the same source of truth

- Improves cost tracking, helping project managers stay on budget

- Enables future-ready design, making it easier to integrate new technologies

Future Developments on the Horizon

As the industry matures, we’re seeing more advanced features on the horizon:

- AI-driven design optimization for automatically suggesting the most efficient rebar layouts

- Virtual Reality (VR) and Augmented Reality (AR) for immersive design reviews

- Enhanced cloud collaboration, enabling global teams to coordinate in real time

Visualizing Success: How 3D Models Enhance Project Outcomes

Streamlined Construction Processes

By visualizing each rebar component in a 3D environment, entire project teams can:

- Order and fabricate rebar precisely, reducing leftover waste

- Place bars on-site with minimal guidance or confusion

- Confirm alignment and load distribution before concrete placement

On-Site Benefits and Improved Coordination

On-site teams gain confidence when referencing a 3D model that aligns with actual field conditions. This coherence between plan and reality fosters:

- Fewer design changes, since potential issues were addressed in digital form

- Reduced site traffic, as tasks are methodically scheduled and executed

- Better communication, ensuring each team member understands their role

Measuring and Celebrating Success

Key metrics like rework rate, labor hours, and material efficiency show clear improvement when 3D rebar detailing is employed. Sharing these successes not only boosts team morale but also cements trust with clients, illustrating your commitment to advanced, reliable construction methods.

Smart Spending: The Cost-Effective Edge of 3D Detailing

Cost-Benefit Analysis of 3D vs. Traditional Methods

Transitioning to 3D rebar detailing can involve an initial learning curve and investment in new software or training. However, project leaders often see a strong return through:

- Lower rework expenses

- Reduced material waste

- Optimized labor utilization

Maximizing Return on Investment (ROI)

Firms can heighten their ROI by:

- Deploying robust training programs, ensuring teams fully understand 3D workflows

- Integrating 3D rebar detailing with broader BIM strategies, amplifying the benefits across all phases

- Leveraging advanced features, like scheduling and real-time updates, to keep projects on track

Real-World Comparisons and Financial Case Studies

Case studies frequently reveal how 3D rebar detailing slashes project overruns and accelerates timelines. By adopting these techniques early in the design phase, companies often save millions of dollars on large-scale builds and significantly reduce operational headaches.

Looking Ahead: The Future of Construction with 3D Rebar Detailing

Emerging Trends in Construction Technology

From robotic rebar tying to AI-driven project management, construction continues to evolve. 3D rebar detailing is a central piece in this puzzle, serving as a reliable cornerstone for complex, tech-forward projects.

Sustainability and Innovation Hand in Hand

More accurate rebar detailing also paves the way for eco-friendly construction:

- Precise material estimates reduce unnecessary consumption

- Efficient workflows help minimize energy use on-site

- Better data collection supports long-term sustainability goals

Final Thoughts

3D rebar detailing stands at the intersection of innovation, efficiency, and sustainability, transforming traditional building approaches into something truly future-ready. By adopting this technology, you’ll cut costs, reduce errors, and bring every stakeholder under one unified vision.