Precision is key in the sphere of steel construction. The structural drawings may reflect design intent, and the detailer brings those ideas to life, making them into buildable, fabrication-ready details. Sadly, a detailing mistake can lead to a colossal problem on the construction site, even when it is small. Structural steel detailing mistakes can doom project schedules, safety, and budgets with expensive delays and disastrous misfits.

Regardless of whether you are a detailer, engineer, fabricator, or a project manager, it is necessary to learn where mistakes have a general tendency of occurring as well as knowing how to avoid them. This blog will bring out the most typical structural steel detailing errors, the reasons behind them, and provide useful hints and tools that can help you completely eliminate them.

What Is Structural Steel Detailing?

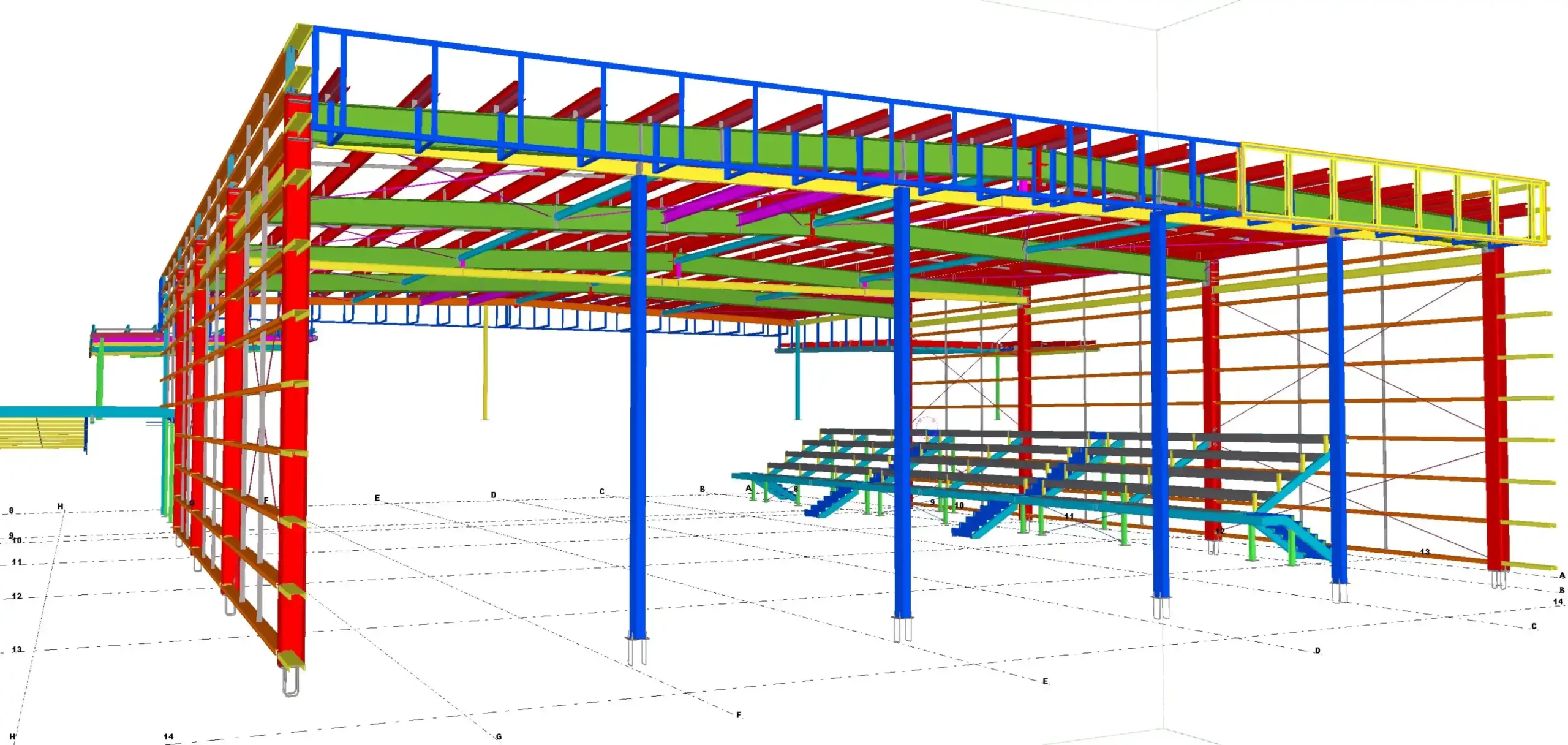

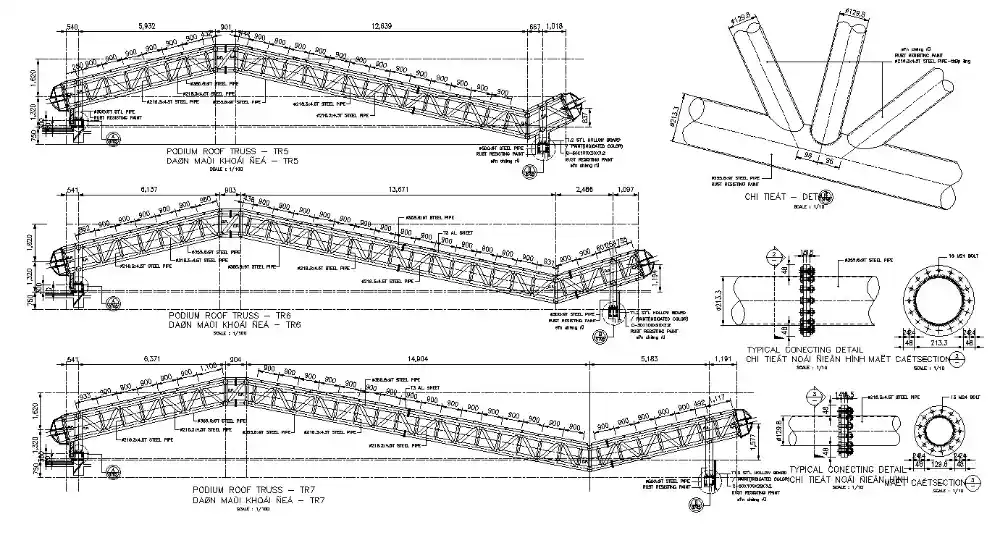

Structural steel detailing technicians draft elaborate drawings and three-dimensional representations that direct the manufacturing and construction process of steel parts. They are beams, columns, braces, trusses, gusset plates, and connection members. The major deliverables are:

- Shop drawings for fabricators

- Erection drawings for site crews

- BOMs (Bill of Materials) for procurement

- Field bolt lists, weld maps, and connection schedules

Detailers represent a linkage between the structural engineers and fabricators, converting the structural intent into directions that could be carried out with the correctness. One error, such as the work labeling the beam or omitting a connecting diagram, can allow delays, rework, or even structural collapse.

This is the reason why structural steel detailing errors are not merely drafting mistakes but are rather high-stakes oversights, whose effects could spread throughout the total project lifecycle. Knowing the role and the task of steel detailing, preconditions catching errors before they turn into problems.

Why Accuracy in Steel Detailing Matters

There is no compromise as far as accuracy in detailing of structural steel is concerned. Detailers provide information that is full, consistent, and accurate which is relied upon by fabricators, erectors, and contractors. Any oversight can lead to:

- Material wastage and reordering

- Fabrication delays due to incorrect cuts or hole placements

- On-site rework from misaligned components

- Costly RFIs (Requests for Information)

- Unsafe conditions during erection

The largest majority of structural steel detailing errors can be categorized into problems such as inaccurate interpretations of design drawings, inability to update changes, or coordination. Field crews can bring work to a standstill even at the smallest problem like in alignment of bolt holes.

Besides, the description of the impacts also influences the whole working process. In the event that the shop drawings are inaccurate, fabricators can get faulty products. In the case of unclear erection drawings, field crews cannot have an easy time doing the installation. What happens in the end is that the level of success of the project depends on the accuracy of your detailing, and that is why you need to learn the most common mistakes thoroughly.

Top Errors in Structural Steel Detailing

Here’s a breakdown of the most frequent structural steel detailing errors, how they affect projects, and why they occur:

Incomplete or Missing Connection Details

Connection details are the most critical part of any steel structure, yet they’re often underdeveloped or omitted altogether. Missing information about weld size, bolt spacing, plate dimensions, or connection geometry can bring fabrication and erection to a halt.

Why it happens:

- Lack of coordination with the engineer of record

- Relying on generic templates without verifying design loads

- Tight deadlines pushing detailers to skip verification

Incorrect Dimensions or Misaligned Members

A few millimeters off in your model could mean the difference between a seamless fit and a major on-site clash. Errors in member lengths, hole spacing, or edge distances often lead to rework, delays, and additional material orders.

Why it happens:

- Poor modeling practices or manual input errors

- Not using automated dimensioning tools in BIM software

- Inadequate quality checks before issuing drawings

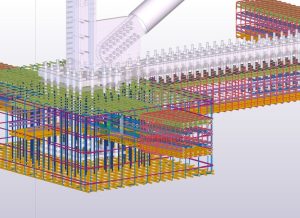

Inadequate Clash Detection

Without proper clash checks, it’s easy to miss collisions between beams, gusset plates, anchor bolts, or MEP systems. These errors may not appear until components are being installed—too late for easy fixes.

Why it happens:

- Working in 2D without integrated 3D coordination

- Lack of collaboration with other trades (MEP, concrete, architecture)

- Rushing modeling without reviewing surrounding elements

Wrong or Outdated Revision Control

Using outdated structural plans or connection details can result in obsolete shop drawings. This leads to the fabrication of incorrect parts, site confusion, and massive delays.

Why it happens:

- Poor version tracking and communication among teams

- Manual drawing management without proper document control

- Failure to update models after receiving revised design files

Mislabeling of Parts or Missing Tags

Incorrect or missing part marks on beams, plates, or bolts can confuse fabricators and erecting crews, leading to misplacement or installation delays.

Why it happens:

- Inconsistent naming conventions

- Manual errors during model exports

- Not using automated tagging features in BIM tools

Lack of Coordination with Engineers/Fabricators

Skipping early-stage communication with structural engineers or shop supervisors results in unbuildable designs or nonstandard connections that can’t be fabricated easily.

Why it happens:

- Assumptions made without confirming constructability

- Pressure to “just get it done” without design validation

- Limited involvement of field expertise in early planning

How to Avoid Common Steel Detailing Mistakes

Avoiding structural steel detailing errors requires more than just experience—it demands a proactive approach rooted in best practices, communication, and quality control. Whether you’re working on a small commercial project or a complex high-rise, these strategies can dramatically reduce costly mistakes:

Implement a Standardized QA/QC Process

Before any drawing is issued, it should go through a thorough internal review. Use a structured checklist to verify:

- Member dimensions and alignment

- Correct weld and bolt specifications

- Connection details as per engineering intent

- Tag consistency across drawings and BOMs

Regular quality checks can catch most structural steel detailing errors before they reach the fabrication floor.

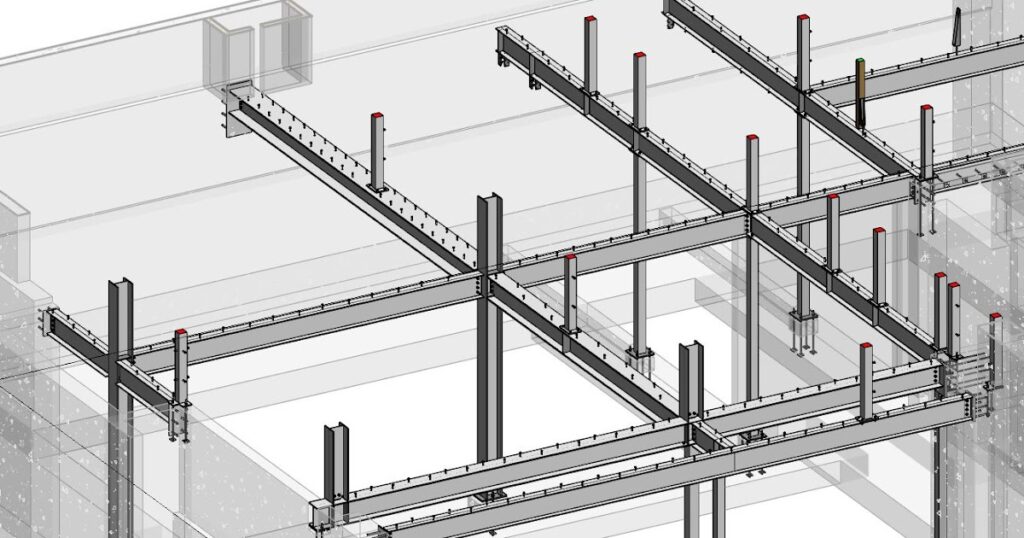

Use 3D BIM Tools to Your Advantage

Modern detailing software like Tekla Structures, Advance Steel, and SDS/2 allows for parametric modeling, automated connections, and built-in clash detection. These tools drastically reduce human error and improve coordination with other trades.

Maintain Clear Communication with Engineers and Fabricators

Regular check-ins with the structural engineer of record and fabrication shops can prevent assumptions or misinterpretations. Discuss:

- Preferred connection types

- Tolerances and fabrication constraints

- Field preferences for erection sequences

Update Models Promptly After Revisions

Any change in the design must immediately reflect in the model. Delaying revisions or working off outdated drawings is one of the leading causes of structural steel detailing errors.

Avoid Over-Detailing

While precision is important, over-complicating details with excessive annotations or unnecessary components can confuse shop floor workers and increase labor time. Keep it clear, buildable, and code-compliant.

By instilling these practices into your workflow, your team can minimize errors, reduce RFIs, and streamline every phase from design to erection.

Role of Technology in Error Reduction

Technology plays a game-changing role in reducing structural steel detailing errors. Transitioning from 2D CAD to intelligent 3D BIM software isn’t just a trend—it’s an industry standard that significantly enhances precision, coordination, and speed.

Here’s how modern tech helps mitigate common detailing issues:

Automated Connections and Smart Components

BIM tools allow users to apply pre-configured connection templates that automatically adjust based on member geometry. This eliminates manual calculations and reduces mistakes related to bolt spacing, plate sizes, or weld types.

Real-Time Clash Detection

Platforms like Tekla Structures can run live interference checks across multiple disciplines. This helps catch:

- Steel-to-steel clashes

- Steel interfering with MEP, ducting, or piping

- Anchor bolt collisions with concrete reinforcements

Identifying these issues in the digital environment eliminates expensive rework on site.

Seamless Integration With Fabrication Software

Advanced detailing software integrates with CNC machines and fabrication management systems. This ensures:

- Accurate cut lengths and hole patterns

- Precise material lists

- Automated data transfer from model to machine

By removing the need for manual data input, these features directly reduce structural steel detailing errors linked to fabrication inconsistencies.

Cloud-Based Collaboration

Cloud-based platforms allow multiple stakeholders—engineers, architects, fabricators—to review and comment on live models. This enhances accountability and ensures everyone works from a single source of truth.

Ultimately, the right tools don’t just speed up the detailing process—they empower teams to deliver higher quality, lower risk, and greater efficiency at every stage.

Final Thoughts

Structural steel is the backbone of modern infrastructure, but even the strongest materials are only as reliable as the drawings that guide their assembly. One miscalculated weld, mislabeled beam, or omitted bolt can set off a chain reaction of cost overruns and construction delays.

Understanding and actively preventing structural steel detailing errors is not optional—it’s a professional responsibility. As projects grow in scale and complexity, the pressure to get it right the first time is greater than ever.