In modern complex building projects, integration of all systems so that they operate efficiently is not an objective, but it is a requirement. With increasingly complicated buildings, with closer spatial tolerances and more interconnected systems than ever before, there has been no greater need for stripped-down coordination between the mechanical, electrical, and plumbing (MEP) disciplines. MEP model coordination comes in as a game changer in this situation.

This blog will delve into the principles and best practices of MEP model coordination, its importance, the price of failing to coordinate, and how to coordinate your models to pursue efficiency, reduce construction errors, reduce schedule slip, and stay on track.

What Is MEP Model Coordination?

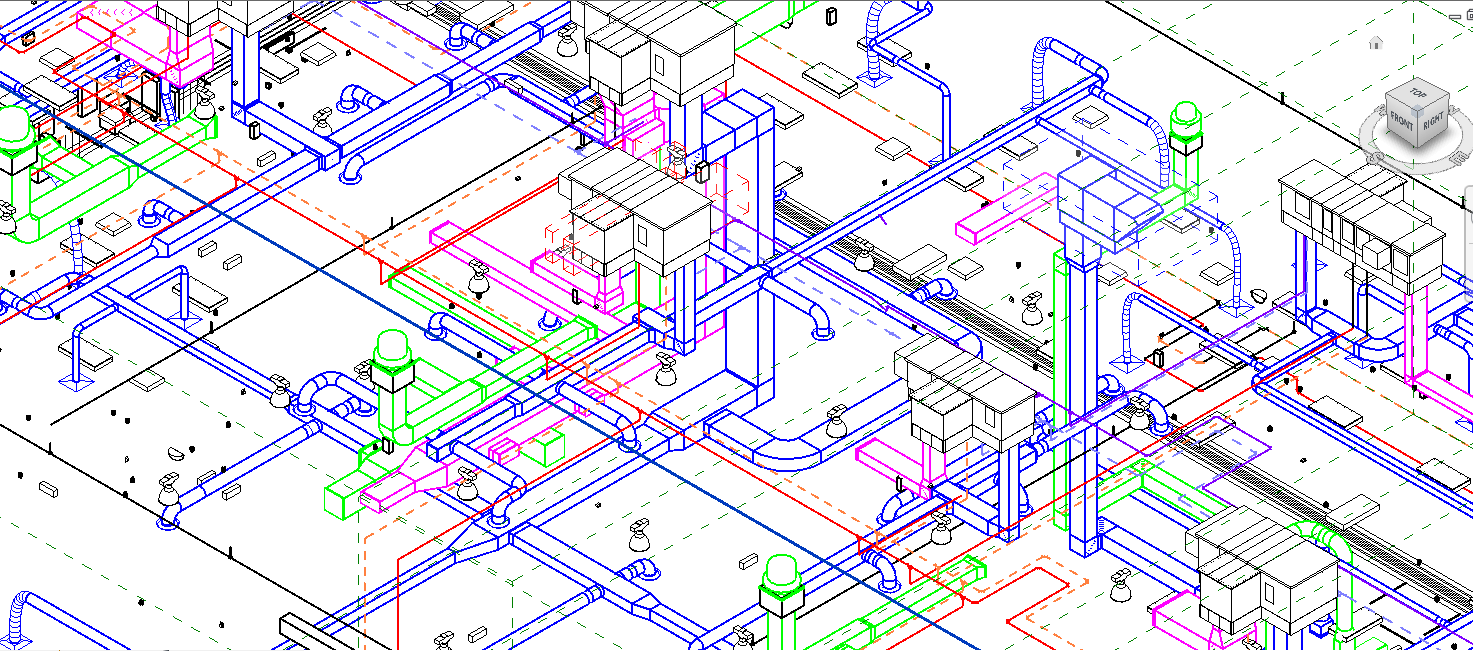

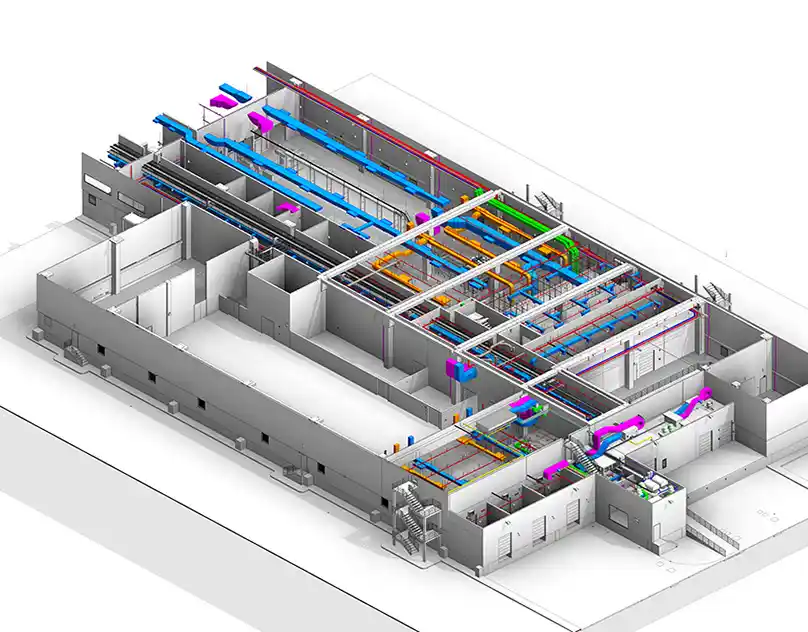

The MEP model coordination is the coordination of the models of mechanical, electrical, and plumbing systems in a single collaborative system so that the spatial and systems conflict can be found and addressed prior to the start of construction. It makes certain that all building systems are oriented to the architectural and structural features, which enables to have a constructive, clash-free design.

The major objective of conducting MEP models coordination is to identify and eliminate interferences like duct work conflicting with structural beams or electrical conduits clashing with plumbing pipes prior to the construction site. It is done through the integration of various models across the disciplines into a coordinated 3D setting to be built on BIM (Building Information Modeling) software.

Key Stakeholders Involved

Effective MEP model coordination relies on cross-functional collaboration. Key participants typically include:

- MEP Engineers: Responsible for the design and layout of system components.

- BIM Coordinators: Manage the federated model and conduct clash detection processes.

- Architects and Structural Engineers: Provide the design constraints and base models.

- Contractors/Subcontractors: Use coordinated models for installation planning and prefabrication.

The High Cost of Rework in MEP Projects

Among the most judicious arguments towards ensuring that coordination of MEP models is given priority is the costly element of design-related rework. Industry surveys cite that as much as 10-15 percent of the total project cost can be used as rework and that MEP systems is amongst the worst hit owing to the level of complexity and interdependency.

Quantifying Rework

Construction waste can be caused by misconnecting the HVAC duct through a beam that can cause demolition, design changes, loss of materials, and time delays in the installation. Problems which barely seem to exist can easily get out of hand and result in costly breakdowns. Improperly integrated MEP systems in a large-scope project, such as a hospital, airport, or high-rise building, can end up costing six figures or more in rework expenses.

Root Causes

The most common causes of rework in MEP projects include:

- Inadequate clash detection during design phases

- Incomplete or outdated models shared between teams

- Design changes that aren’t communicated across disciplines

- Lack of standardized workflows or coordination protocols

Each of these factors highlights the importance of adopting a proactive, standardized approach to MEP model coordination from the very beginning of the project.

Benefits of Effective MEP Model Coordination

At Strand Co, we know that meaningful results can only be achieved through the proper coordination of MEP models. Located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, we support clients across Long Island and the surrounding areas by ensuring seamless integration of mechanical, electrical, and plumbing systems. From design and installation to facility operation, our coordination services eliminate guesswork, accelerate decision-making, and ensure every system is fully constructible in a real-world setting. For personalized assistance, feel free to call us at (631) 805-3179—we’re here to help streamline your project at every stage.

Fewer RFIs and Change Orders

The co-ordinated models significantly cut down the field-generated RFIs (Requests to Information) and the expensive change orders. In a scenario whereby the conflict in MEP is solved in the design process, construction teams are not obliged to halt work and await clarification or redesign.

Reduced Field Conflicts

The rational and logical system routing, due to proper MEP model coordination, guarantees an efficient running of the systems. This reduces the chances of conflicts in trade within the site where the plumbing might interfere with the HVAC ductwork, or where an electrical conduit might interfere with a structural component.

Improved Project Scheduling

Trade sequencing is more predictable because there are fewer surprises on-site. It is possible to arrange prefabrication with certainty, and the total project schedules will be more realistic and achievable.

Enhanced Collaboration

The properly performed coordination process provides the active interaction among architects, engineers, and contractors. Cloud-based platforms also support collaboration as all teams can work in an environment consisting of one centralized and real-time model.

Cost Savings and Value Engineering

Early resolution of spatial conflicts aims at avoiding material waste and labor inefficiency, which are quite expensive. Value engineering also happens to be supported by MEP model coordination, which enables the teams to streamline system layouts in terms of cost and performance prior to the start of construction.

Best Practices to Reduce Rework in MEP Coordination

Best practices, which are the ones that others have proven to be effective, can easily improve effectiveness and efficiency of your model coordination process in MEP. The sooner and in more steady ways such practices are implemented, the larger the decrease in rework and project risk.

Start Early with Coordination

MEP coordination has to be initiated at the following phase, either schematic design or design development stage, and not on construction documentation. The earlier the conflicts are detected, the easier they are detected and resolved before they are entrenched in construction documents.

Use a Federated BIM Model

In a federated model, all systems’ architectural, structural, and MEPs are added into a single and coordinated file. It is the basis of successful MEP model coordination. Teams can see all the information in the context of all the building systems and do clash detection in detail.

Implement Robust Clash Detection Workflows

The tests on clash detection should also be performed using software such as Navisworks Manage or Solibri. Fix the most important conflicts (e.g., ductwork vs. structural beams) first rather than the less important ones (e.g., light fixture overlapping sprinkler heads). Keep clash issue logs and fix items prior to model freeze.

Standardize Modeling Protocols

Use the same naming conventions, object families, and Levels of Development (LOD). The uniformity of these aspects across different fields enhances the efficiency of coordination. A good BIM Execution Plan (BEP) that defines coordination tasks and expectations is needed in the direction of MEP model coordination.

Conduct Regular Coordination Meetings

Model review each week or biweekly gives all the disciplines an opportunity to discuss conflicts and settle on resolutions. Model markups, live walk-throughs, and shared screens can be used to accelerate the decision-making process and give rise to accountability.

Assign Clear Responsibilities

The architectural layout problems might require redesign by the architect, whereas duct rerouting might be under the mechanical team. The ownership is clear during the coordination as it eliminates finger-pointing and delays.

Leveraging Technology for Smarter Coordination

Technology plays a pivotal role in modern MEP model coordination—enabling teams to detect issues early, communicate effectively, and execute more predictable projects. Selecting the right tools and workflows can significantly reduce rework and boost coordination efficiency.

BIM Collaboration Platforms

Platforms like Autodesk BIM 360, ACC (Autodesk Construction Cloud), and Trimble Connect offer centralized access to live models, issue tracking, and markup tools. These cloud-based platforms empower distributed teams to collaborate in real-time—keeping everyone aligned with the latest model versions.

Automated Clash Detection Tools

Clash detection software such as Navisworks Manage, Solibri, and Revizto allow users to detect thousands of conflicts instantly. These tools also categorize and prioritize clashes, making MEP model coordination more data-driven and organized.

Use of Point Cloud Scans for Renovation Projects

Laser scanning and point cloud data provide precise as-built conditions for retrofits and renovations. Integrating this data into your MEP model coordination process helps ensure your designs are based on real-world conditions—eliminating spatial surprises during construction.

Measuring Coordination Effectiveness

Tracking the performance of your MEP model coordination process is essential for continuous improvement. Here are key metrics to monitor:

- Clash Rate: Track the number of clashes per 100 square meters or per model iteration. A declining clash rate signals better modeling discipline and coordination quality.

- Resolution Time: Monitor how long it takes to resolve coordination issues. Delays in clash resolution may indicate communication gaps or unclear ownership.

- Coordination KPIs

- % of unresolved issues at each milestone

- Number of model iterations required

- RFI trends before vs. after coordination

- % of trades using the federated model for installation

- Dashboards and Reporting: Leverage BIM dashboards to visualize and report progress in real time. These help stakeholders make data-informed decisions and stay aligned with coordination goals.

Conclusion

At Strand Co, located at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, we understand that MEP model coordination may not seem like a value-add at first glance—but in today’s construction landscape, it’s absolutely essential. While it’s a requirement, its true value is both evident and long-lasting. From reducing re-work and avoiding costly delays to enhancing collaboration, managing budgets more efficiently, and improving communication, the benefits are undeniable.

By initiating coordination early, using the right tools, and following standardized processes, we help our clients avoid common project pitfalls. This leads to more predictable outcomes and consistently profitable results. A clash-free, thoroughly coordinated MEP model is the foundation for smoother installations and fewer change orders down the line. For expert assistance and project success, give us a call at (631) 805-3179—we’re ready to support your goals from concept to completion.