The implementation of structural engineering design represents the key stage of development. Construction projects depend on it for building solid versions of architectural visions while maintaining safety.

This handbook demonstrates the necessary 7 procedures needed to establish buildings with robust structures beginning with initial design ideas and extending until site construction begins. Through this process students will acquire fundamental structural engineering knowledge and learn about structural analysis methods as well as plan generation and drawing creation processes for construction direction.

Finding information about structural components alongside their analysis and the typical period needed for building structural engineering is available at this site. Conceptual design represents the first step for creativity in the sequence of phasing.

What Is Structural Design and Why It Matters

Structural design is the engineering process of creating a building’s “skeleton” so it can safely carry all the loads it’ll ever face—everything from the weight of the walls and floors (dead loads) to people moving around (live loads) and even forces like wind or earthquakes. By selecting the right materials (steel, concrete, timber), arranging beams and columns in smart layouts, and running detailed simulations to check strength and stiffness, structural design ensures that your building not only stands tall but also stays safe and stable throughout its life.

Step 1: Conceptual Design

The architectural vision transitions into a form that builders can construct during this phase of our architectural BIM services. The conceptual design phase involves planning methods for selecting suitable structural building systems according to architectural targets, site characteristics, funding requirements and functional needs of the structure.

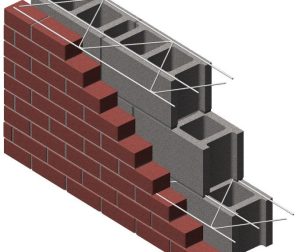

The collaboration between structural engineers and architects helps determine which material system the structure will use—concrete, steel or timber. Engineers evaluate the structural requirements through grid formation and column placement together with beam dimensions, while also exploring foundation options to balance structural capabilities and aesthetic appearance.

Afterward, the preliminary structural plan demonstrates spatial organization of metal structural components and selected materials—showing slab configurations, load-bearing walls and lateral system arrangements—as part of the presentation modeling stage. The crucial nature of this phase lies in determining how structural components will support loads that will occur in the future, all while adhering to the architectural design requirements.

This is where structural development begins in earnest, setting the stage for detailed analysis and subsequent design work.

Step 2: Load Analysis

Before starting detailed design work, engineers must first identify the distinct forces which will affect the structure. Building structure analysis requires engineers to determine both outside forces and inside forces that buildings must withstand during every stage of their existence. These include:

- Dead Loads: The permanent weight of the building itself (walls, slabs, beams, finishes)

- Live Loads: Variable forces like people, furniture, vehicles, and equipment

- Environmental Loads: Wind, seismic activity, snow, temperature, and even flooding

Engineers apply building codes alongside industry standards to conduct multiple structure analysis trials thus determining different load combination effects on buildings. The comprehensive analysis helps maintain safety by applying safety factors to worst-case situations along with their appropriate utilization.

Engineers establish foundational work at this stage for future drawings of load-bearing element positions and paths.

Step 3: Structural Analysis

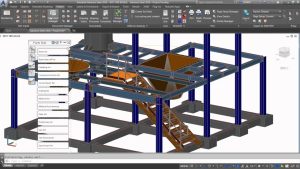

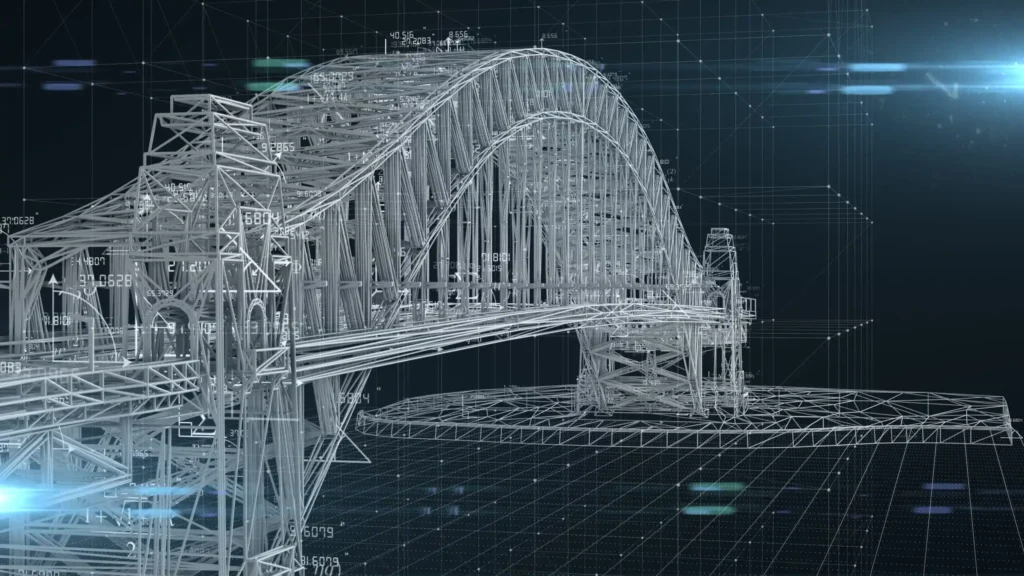

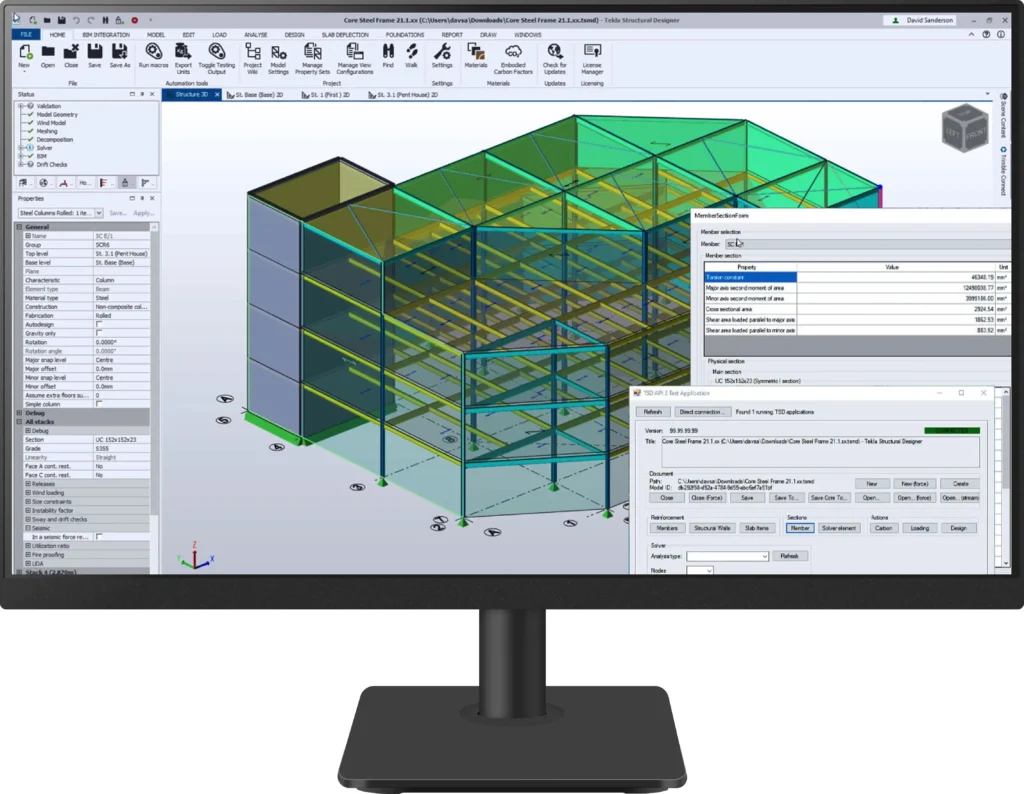

The structural analysis becomes the central element of the design process after all loads have been properly defined. Engineers utilize software coupled with engineering equations to model the frame’s reactions to calculated loads during this simulation step.

Modern engineering practice creates building system modeling through tools including ETABS, STAAD.Pro, SAP2000 and Revit Structure designed to conduct evaluations of 2D and 3D building systems.

- Bending moments

- Shear forces

- Axial loads

- Deflections and sway

- Vibration behavior

Designers aim to verify that all structural components such as beams, columns and slabs and braces possess adequate strength to bear anticipated loads during normal use. The testing phase confirms that the building possesses necessary strength and stiffness as well as maintains overall stability.

Building code compliance through proper structural analysis serves as the starting point for producing accurate drawings both for metal structural components and final site use structural drawings.

Strong emphasis should be placed on this step because complex structures and dangerous earthquake-prone areas require specific attention. Skilled use of this methodology decreases future structural problems while enabling easier construction operations.

Step 4: System Design

Once the load-bearing behavior is confirmed through structural analysis, engineers move into system design—a critical phase where the structural framework of the building is solidified.

In this step, the structural engineer selects and sizes the major structural systems:

- Beam and girder systems

- Column and support layouts

- Floor and roof framing systems

- Lateral force-resisting systems (shear walls, braces, moment frames)

The focus is on choosing components that work together to resist gravity and lateral forces efficiently. These elements are aligned with architectural spaces, mechanical systems, and construction constraints.

At this stage, structural engineering design applies to actual project needs. Engineers start preparing diagrams for structural drawings which demonstrate the assembly process for builders. Engineers produce fabricating drawings for steel beams alongside joists and rebar schedules at this time.

The planned structural arrangement during this stage delivers higher constructability with less material waste and safer outcomes.

Step 5: Element Detailing

Structural engineers carry out element detailing subsequent to completing the systems phase.

Accurate drawings of all beam, slab, footing and column elements receive finalization in this phase. The structural drawings now include drawings of cross-sections while displaying reinforcement details together with connection types and material specification information along with anchoring procedures.

This step is particularly important when preparing metal structural component drawings, such as:

- Steel connections and baseplates

- Rebar placement in concrete beams

- Welding and bolting layouts

- Slab edge profiles and control joints

The design evolution during detailing creates documentation suitable for contractor and fabrication work. Drafting structure-based designs requires the most intensive effort during this phase because it needs both precision and conceptual understanding.

Absolute beginners to structural engineering can understand through this stage how much technical planning and collaboration are required to complete a single bolt or weld.

Step 6: Iterative Design and Drafting

The process of structural engineering works through repeated, continuous development rather than linear progression. The team uses feedback along with constructability issues and cost update,s and changes to architectural designs to make improvements to the design.

Pursuing design alterations for both the structural plan and drawings remains standard practice in this stage because safety requirements and costs and efficiency objectives need to be reconciled. Engineers and drafters perform ongoing updates to the drafts which incorporate both engineering changes together with architectural revisions.

This step may also involve:

- Additional structure analysis for modified areas

- Coordinating with MEP and architectural teams

- Ensuring code compliance during design evolution

For project owners asking, what is the average time for structural engineering for a building, this step often accounts for the variability. Additional revisions or updates during the process may prolong construction duration by weeks but they promote outcome coordination and decrease construction field mistakes.

Step 7: Construction Administration

The final step in the structural engineering design journey is construction administration. Even with detailed structural drawings, on-site execution needs ongoing oversight.

In this phase, the structural engineer provides support during the build process by:

- Reviewing shop drawings and submittals

- Answering RFIs (Requests for Information) from contractors

- Making field adjustments when unforeseen conditions arise

- Ensuring structural work is executed per the approved design

Site visits, coordination with the GC, and structural inspections are key to verifying that what’s built matches the drawings. This phase protects the design intent, upholds structural integrity, and catches mistakes before they become costly problems.

Ultimately, building structural success depends not just on good design, but on making sure it’s followed through in the field. Construction administration bridges that final gap—bringing your project to life, safely and structurally sound.

Conclusion

A structural design project requires careful planning, a well-organized workflow, and consistent collaboration between all team members. From the conceptual design phase to the final construction administration, each stage plays a critical role in ensuring that the building is safe, durable, and sustainable.

By following a structured approach and using the right tools, you can streamline the structural engineering design process, reduce errors, and avoid costly delays. Remember that success lies in clear communication, strategic planning, and adaptability throughout the project lifecycle.For your next structural design project, trust the experts at Strand Co to deliver top-tier structural analysis, detailed structural drawings, and accurate construction documentation. With a focus on collaboration and efficiency, we are here to bring your vision to life, from concept to construction.