The first thing that comes to the mind of the majority of professionals when they mention Autodesk Revit is the 3D visualization, architectural modeling, and coordination. Nevertheless, there is more than the strong modeling features, and there is a potent data-powered engine, which can change the way in which we manage project finances.

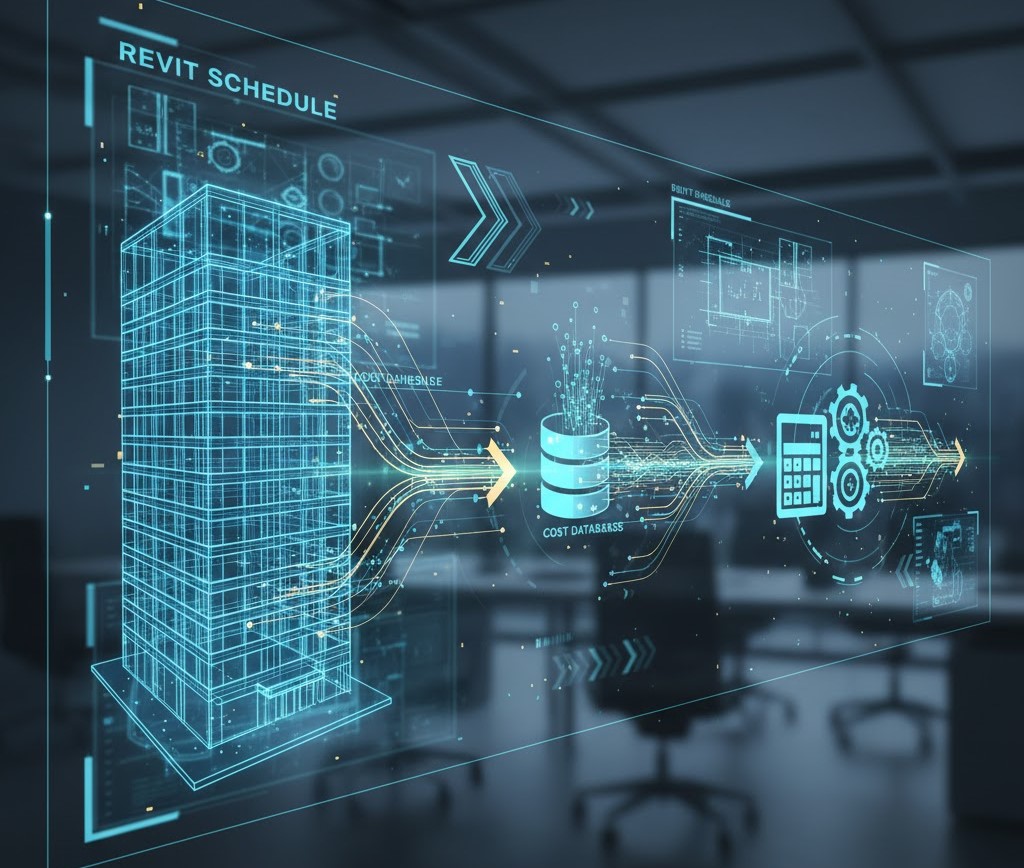

Revit schedules help architects, engineers, and estimators to transform the design data into accurate cost estimation data, which helps bridge the gap between design intent and financial planning. Rather than depending on manual quantity takeoffs or spreadsheets, which are subject to human error, Revit allows you to automatically derive material quantities and use cost parameters in real time.

In this blog, we will discuss the use of Revit schedules to estimate costs, and we will go beyond the visualization process to develop an all-encompassing, smart costing and decision-making process.

Understanding Revit Schedules

What Are Revit Schedules?

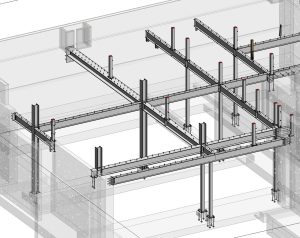

A schedule in Revit is not a simple list, but it is a dynamic table that retrieves and presents real-time data in the model. It can be the walls, floors, beams, doors, or mechanical equipment; all modeled items in Revit have information-rich data, or parameters.

Revit schedules are structured tables that display the data to the user in terms of quantities, dimensions, materials, and sometimes cost information. The real benefit of these is that they are parametric schedules in the sense that they update automatically with a change in the model.

This dynamic connection of model and data also makes Revit schedules inevitable in the design documentation and cost estimation processes.

The Role of Data in BIM

Revit is based on the fundamental philosophy of Building Information Modeling (BIM), in which each component is not geometry but a database of information.

Each wall, door, or column is aware of what it is composed of, its dimensions, its manufacturer, and probably its unit price.

This makes the model a single source of truth where design, construction, and financial information are present. Revit schedules can be used to convert visual design into actionable and measurable intelligence by tapping into this data.

Why Use Revit Schedules for Cost Estimation?

The conventional cost estimation was based on the 2D drawings and manual takeoffs—a process that usually produced inconsistent and outdated information. Any change was a recalculation that resulted in numerous errors, loss of time, and increased costs.

This process is automated with Revit. Quantities are always accurate and up-to-date since all data is incorporated in the model. This minimizes the chances of human error, and real-time conformity between design and budget is achieved.

The BIM Advantage

Using Revit for cost estimation provides several unique advantages:

- Instant updates: any design modification automatically adjusts quantities and costs.

- Collaboration among architects, engineers, and estimators works from the same model.

- Transparency project stakeholders can visualize the financial impact before implementation.

- Efficiency eliminates redundant manual entries across multiple platforms.

How Revit Schedules Improve Project Decision-Making

Attempting to link the quantities and costs of materials and designs dynamically enables the teams to make informed decisions in the early stages. To illustrate, when changing one material of cladding to another in a schedule, instant cost implications are visible immediately, assisting teams to compare design options based on available budgets.

Types of Revit Schedules Used in Cost Estimation

Material Takeoff Schedules

In Revit, a material takeoff pulls out particular material quantities of the model items. It enables you to quantify the amount of concrete, steel, glass, or paint that you need to use—automatically.

An example of this is a type of wall that can show the total volume of concrete or square footage of plaster finish in real time, and this is accurate for the material.

Quantity Schedules

These schedules include amounts of certain types of elements—such as walls, doors, windows, beams, and floors. The cost estimation is based on quantity schedules, which enable you to multiply unit costs by the units of the elements to get a summary of the budget in a short period.

Keynote and Parameter-Based Schedules

By using custom parameters or keynotes, you can attach cost codes, supplier data, or pricing structures to elements. This data can later be exported or linked with estimating software, bridging the gap between BIM and financial databases.

Multi-Category and Element-Specific Schedules

Multi-category schedules are used when dealing with complex projects to combine the information of various types of elements into one table. Multi-category schedules are flexible enough to allow detailed analysis of costs, whether you are estimating finishes, fixtures, or the MEP equipment.

Step-by-Step: Setting Up Revit Schedules for Cost Estimation

Preparing Your Model

Before creating schedules, ensure your Revit model is data-consistent:

- Families should have parameters like Type Mark, Material, Volume, and Cost.

- Naming conventions should follow a standardized template.

- The Level of Development (LOD) should match your project phase (e.g., LOD 300 or 350 for estimation).

A clean and standardized model ensures the schedule extracts reliable data.

Creating a Schedule

Follow these steps:

- Go to View Tab → Schedules → Schedule/Quantities.

- Choose the element category (e.g., Doors, Walls, Floors).

- Select fields like Type, Count, Area, Volume, and Cost.

- Add sorting and grouping (by level, material type, or system).

- Apply filters to focus on relevant elements only.

You now have a live, data-driven schedule ready for refinement.

Adding Cost Data

Add Unit Cost and Total Cost parameters:

- Input unit costs manually or import from an external Excel file.

Use calculated fields such as Total Cost = Unit Cost * Volume

- This automatically updates costs when material quantities change.

Customizing and Formatting

Use conditional formatting to highlight high-cost elements or anomalies.

Customize headers, fonts, and sorting for easy readability.

Finally, export your schedule to Excel or PDF for presentations or financial analysis.

Integrating Revit Schedules with Cost Databases and Estimation Tools

Exporting Schedules to Excel

Revit allows you to export schedules directly to Excel, where cost estimators can further refine or integrate data. This hybrid workflow helps maintain the live connection between design and cost, even when external systems are used.

Linking with Third-Party Estimation Tools

Revit schedules can integrate with several estimation platforms, such as:

- CostX

- Innovaya

- Sage Estimating

- Assemble Systems

- Navisworks Quantification

Through shared parameters and IFC data exchange, estimators can push data between Revit and external tools—enabling 5D BIM workflows that combine design, time, and cost.

Automation Through Dynamo and Revit API

Advanced users can harness Dynamo or Revit API scripts to automate:

- Pulling live cost data from databases.

- Updating unit prices periodically.

- Creating automated reports for cost summaries.

This approach reduces repetitive manual work and ensures cost data remains synchronized with the model.

Common Challenges and How to Overcome Them

| Challenge | Solution |

| Incomplete or missing parameters | Standardize shared parameters across the project. |

| Inconsistent naming conventions | Develop company-wide BIM templates. |

| Overly complex schedules | Break large schedules into categories or phases. |

| Rapid cost fluctuations | Integrate dynamic cost data from suppliers or update manually on a fixed cycle. |

| Limited team understanding of Revit estimation tools | Conduct BIM training and workshops for cost teams. |

These solutions ensure that your Revit-based cost estimation remains reliable, transparent, and scalable across all project phases.

The Future of Cost Estimation with Revit

The future of cost estimation is shifting to automation, integration, and intelligence.

- The AI estimation tools will provide insights into predicted costs using historical data of the project.

- The 5D BIM processes will combine design, scheduling, and cost into a single setting.

- Cloud-based teamwork will enable teams all over the world to see real-time cost updates in common Revit models.

In a changing world of technology, Revit is set to be the center of focus—the bridge between design creativity and data accuracy to achieve improved project results.

Conclusion

The strength of Revit goes far beyond simple visualization, especially for AEC firms here in Hauppauge, NY. It has become one of the most productive tools for estimating costs through data because of its powerful scheduling abilities. When teams integrate all materials and elements in the model with the cost data, the financial decisions they make become faster, smarter, and more informed across the entire project lifecycle.

Revit schedules also make it easier to bring cost estimates directly into the design phase. This lowers the amount of manual work, improves collaboration among local project teams, and increases the accuracy of every design. In this way, Revit transforms design information into quantifiable knowledge that supports better project planning and budgeting.

If you want to bring your BIM process to the next level with data-driven cost estimation, STRAND Consulting offers specialized support right here in Hauppauge. Our team focuses on Revit design, BIM scheduling, and detailed cost estimation to help you achieve financial precision and operational efficiency in every project.

Contact STRAND Consulting today at (631) 805-3179 to learn how you can incorporate Revit-based cost estimation into your upcoming work and go beyond visualization in your BIM process. You can also visit us at 490 Wheeler Rd, Suite 108, Hauppauge, NY 11788, USA, or find our location through this link: https://maps.app.goo.gl/6QPGiXRxNgQyX4aX8.