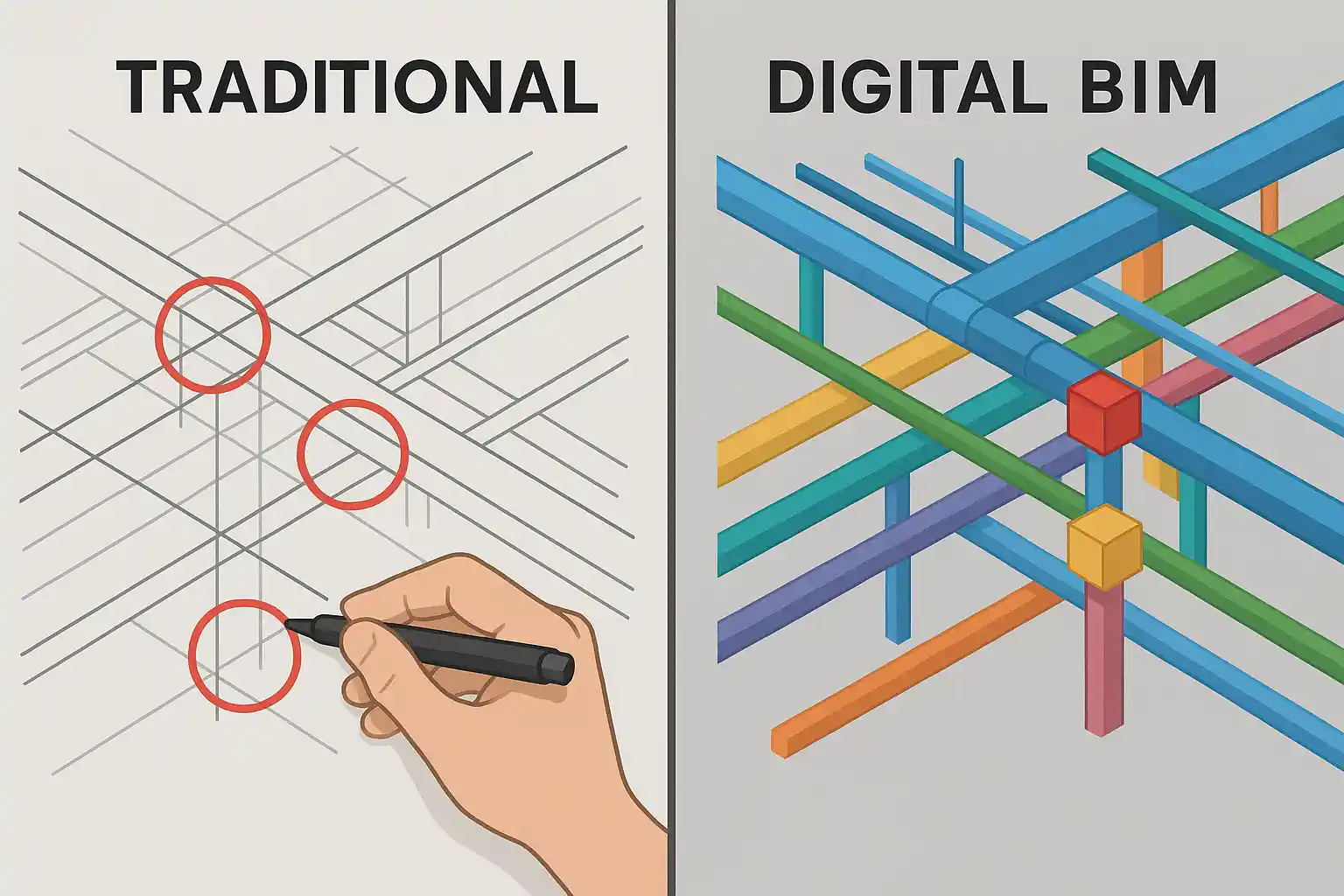

In today’s construction and design world, Building Information Modeling (BIM) has changed the way teams deal with complicated tasks. Frequently, it helps in clash detection, which involves finding and fixing conflicts in construction before any physical work takes place. Even so, some clash detection systems are better than others.

In the following paragraphs, we’ll examine the main differences between standard and digital BIM clash detection, show how they wor,k and explain their pros and cons, especially regarding trends in the industry.

What is Clash Detection?

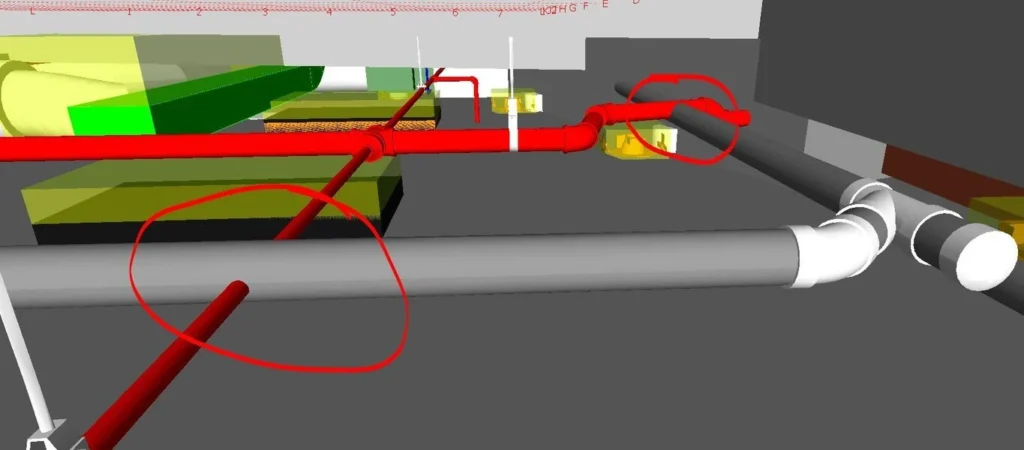

Clash detection refers to the process of identifying conflicts (or “clashes”) between different building components in a design. These clashes can be:

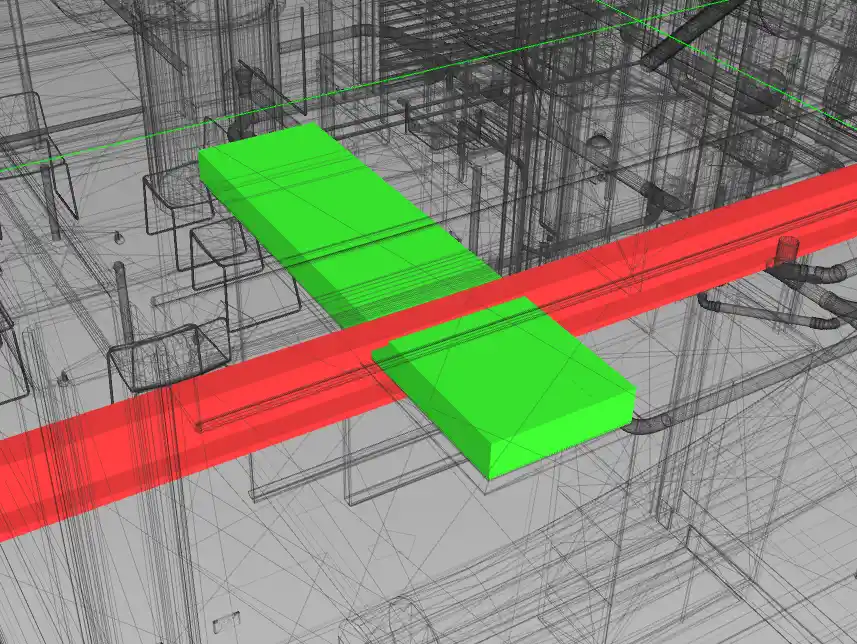

- Hard Clashes: Physical overlaps between elements (e.g., ductwork running through a beam).

- Soft Clashes: Spatial conflicts (e.g., clearance or buffer zone issues).

- Workflow Clashes: Scheduling or sequencing conflicts (e.g., trying to install HVAC before concrete curing is completed).

Clash detection is vital for reducing errors, delays, and costs associated with design conflicts discovered during or after construction.

Traditional Clash Detection: Manual & 2D-Based Approach

Usually, finding clashes in traditional software required using two-dimensional drawings, hand-made models or putting overlays on light boards. Engineers, architects and contractors checked and compared different kinds of drawings (like mechanical, structural and electrical) to spot any issues.

Process

- Print or overlay 2D CAD drawings from different disciplines.

- Manually compare for physical conflicts.

- Use highlighters or markups to flag issues.

- Conduct in-person coordination meetings to resolve problems.

Key Features

- 2D Drawing-Based Analysis: Uses manual review of 2D CAD drawings or blueprints

- Manual Overlays: Physical overlaying of printed drawings

- Human-Driven Identification: Clashes are spotted by experienced professionals using visual inspection and construction knowledge.

- Physical Markups and Notes: Conflicts are typically marked using pens, highlighters, or sticky notes on printed documents.

- Discipline-Specific Workflows: Each trade works in silos, coordinating manually at predefined stages.

Digital BIM Clash Detection: Intelligent & Automated

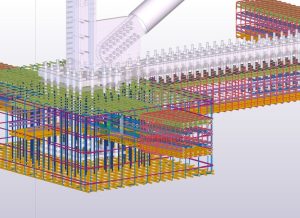

Digital BIM clash detection uses 3D BIM models and software tools like Navisworks, Solibri, Revit, and BIM 360 to automatically detect design conflicts between disciplines.

It enables automated, real-time clash identification in a centralized digital environment, fostering collaboration and early issue resolution.

Process

- Combine discipline-specific 3D models into a single federated BIM model.

- Use clash detection software to run automated checks.

- Identify and categorize clashes (hard, soft, workflow).

- Assign, track, and resolve clashes using issue management tools.

- Update models to reflect changes in real time.

3. Key Features of Digital Clash Detection

- 3D visualization: Full spatial understanding of conflicts.

- Automation: Rapid detection of thousands of clashes.

- Real-time coordination: Stakeholders can collaborate remotely.

- Data-rich environment: Models contain metadata for smarter decision-making.

- Documentation and tracking: Issues are logged with timestamps and responsibilities.

Traditional vs Digital BIM Clash Detection: Side-by-Side Comparison

| Feature | Traditional Clash Detection | Digital BIM Clash Detection |

| Method | Manual, 2D-based | Automated, 3D-based |

| Accuracy | Subjective and error-prone | Highly accurate and objective |

| Visualization | Limited (flat drawings) | Comprehensive (3D walkthroughs) |

| Efficiency | Time-consuming | Fast and scalable |

| Data Integration | Low | High–link design and metadata |

| Real-Time Collaboration | Rarely possible | Fully supported |

| Clash Types Detected | Mostly hard clashes | Hard, soft, and workflow clashes |

| Documentation | Paper-based or static markups | Dynamic logs and issue tracking |

| Cost Savings | Minimal | Significant reduction in rework and change orders |

Real-World Impact of Digital Clash Detection

1. Improved Project Outcomes

Digital clash detection contributes to:

- Fewer change orders

- Reduced rework

- Shorter construction timelines

- Improved cost control

2. Enhanced Collaboration

Cloud-based tools (e.g., Autodesk BIM 360) enable:

- Simultaneous model access

- Clash issue tracking

- Automatic notifications

- Cross-discipline transparency

3. Data-Driven Decision Making

Digital models allow stakeholders to base decisions on:

- Accurate quantities and dimensions

- System performance simulations

- Risk analysis

- Real-time status tracking

Challenges of Traditional BIM Clash Detection

Before, clash detection depended on people looking through drawings, physical models or layers of transparencies on light tables. Prior to intelligent BIM models, teams comprising engineers, architects and contractors would review various sets of drawings (mechanical, structural, electrical, etc.) in search of inconsistencies or overlaps. While important in the start of design coordination, this approach has some built-in issues:

1. 2D Limitations and Lack of Spatial Awareness

Checking for clashes in old methods relies more on 2D drawings than on ones with good spatial dimensions. It is hard to see how different components fit in a 3D space without a 3D model, which may result in missed clashes that appear once construction begins.

2. Time-Consuming Manual Processes

To compare drawings from different engineering fields—architecture, structure, mechanism, and electricity—takes a lot of time and needs a lot of coordination. Looking for areas where drawings match or using light tables to superimpose plans happens slowly and might cause mistakes.

3. Human Error and Inconsistency

Traditional clash detection uses judgment, so it is often subject to personal opinions. What issues a reviewer finds will vary, and it is quite possible that some reviewers may miss potential conflicts in challenging or busy parts of the design.

4. Delayed Conflict Identification

Many conflicts are realized late during the project, sometimes not until the construction phase is already started. The response-based approach can lead to big expenses, changes made to the projec,t and delay the completion of the work.

5. Poor Interdisciplinary Communication

Traditionally, team members usually worked by themselves in silos. It’s common for architects, engineers and contractors to communicate poorly, mostly when the versions of the same drawing are not the same. Because of this division, people can make wrong decisions or assume things that do not match.

6. Inefficient Documentation and Tracking

Back in the day, marking up issues meant handling actual copies of the paper and kept issue tracking slow. Managing and resolving each conflict is a challenge when there is no central place to keep records.

7. Minimal Insight into Constructability

Because the traditional method lacks intelligent modeling data, there’s little to no support for analyzing sequencing, installation feasibility, or long-term maintenance access, limiting insight into real-world constructability.

Challenges of Digital BIM Clash Detection

Even though BIM-based clash detection is very useful, it does have its own limitations. Most commonly, such challenges involve data being safe, the technology performing properly, and people’s computer know-how.

1. Dependence on Model Accuracy and Completeness

The quality of the clash detection results depends on having accurate models. If all the input data is not complete, out of date, or misrepresented, it may result in false positives or the process missing some real issues. Bad information is processed and becomes bad results.

2. High Learning Curve and Need for Skilled Professionals

Digital BIM apps like Navisworks, Solibri, or BIM 360 require someone with advanced technical knowledge to use them. A wrong interpretation of clash reports can result in chaos around clash placement, a lack of structure in assigning work, and misplaced effort on resolving clashes.

3. Software and Hardware Costs

Digital clash detection must be supported with software license payments, hardware improvements, and regular updates. It can be tough for small companies or those managing a tight budget to get enough money for this software.

4. Interoperability Between BIM Platforms

Different people involved in construction may use their own BIM software which can result in issues when files are shared. Sometimes, following IFC standards alone is not enough to avoid errors during model integration; this can affect how well clashes are detected.

5. Overwhelming Number of Clashes (Noise vs. Signal)

Usually, when clash detection happens automatically, many of the clashes it spots can be forgotten because they are minors or unimportant. Without choosing right issues for discussion, teams might spend hours on problems that are not important.

6. Lack of Standardized Workflows

Although advanced technology is available, most teams use their own ways to perform clash detection. Disagreements in how jobs are named, the level of tolerance and what each person’s role is may cause misunderstandings and unsolved disputes.

7. Resistance to Adoption

Local culture being strong in companies or among subcontractors can block progress. Some teams may hesitate to use new digital processes which means BIM can take longer to be fully adopted and its benefits may be limited.

Best Practices for Successful Clash Detection with BIM

To maximize digital clash detection’s effectiveness:

- Standardize model coordination protocols.

- Use a Common Data Environment (CDE) for file sharing and version control.

- Schedule regular clash detection meetings during design development.

- Assign clear responsibilities for clash resolution.

- Continuously update models with resolved issues to avoid regression.

- Integrate with 4D (schedule) and 5D (cost) BIM for greater insight.

Conclusion: The Future is Digital

While traditional clash detection paved the way, its limitations are too significant in today’s fast-paced construction environment. Digital BIM clash detection offers unmatched speed, precision, and collaboration opportunities. As project demands grow more complex, embracing digital tools is not just a competitive advantage—it’s a necessity.

By transitioning from traditional methods to digital clash detection, firms can avoid costly mistakes, deliver projects faster, and build with greater confidence.