Time and accuracy are everything in the high-paced structural steel building profession. A single delay at the location has the potential of creating chain repercussions- cost overruns and missed deadlines, and resource clashes. That is where erection drawings prove to be priceless. They are not mere technical drawings but field-oriented diagrams that provide a guide to possible productivity on-site assembly.

This blog goes into details of why having erection drawings is not a formality but a strategic requirement. Through accelerating unpackings to minimize field hustle and bustle, we shall discuss how quality erection drawings can end up changing the architectural landscape drastically from the current progress. Be it a project manager, steel detailer, or construction supervisor, it is important to know their role to make your project executions more efficient.

What Are Erection Drawings?

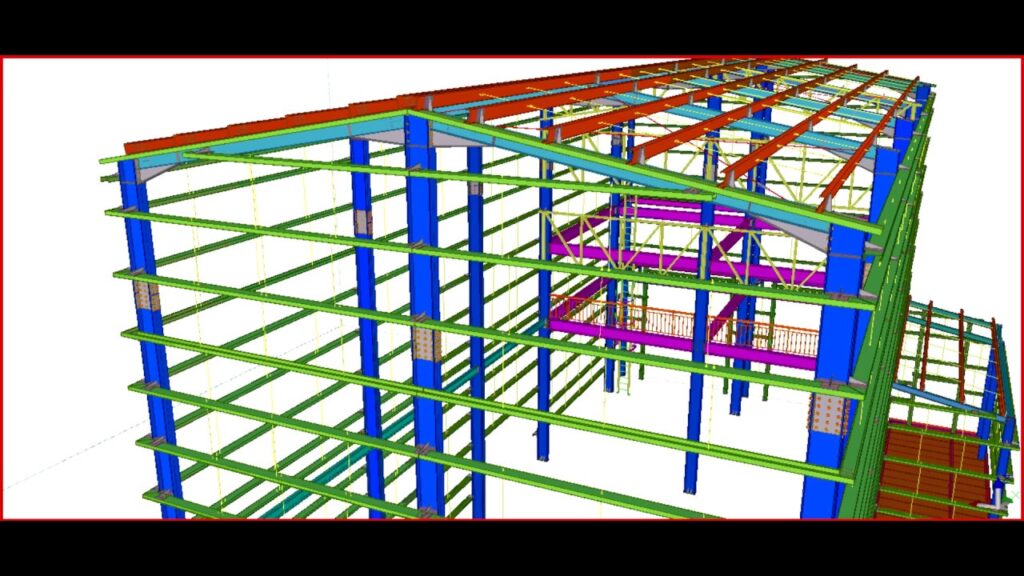

Erection drawings are specialized construction drawings to direct the on‑site assembly of steel structures. They show actual, graphical information telling manufacturers how steel parts—including beams, columns, braces, and trusses—must be aligned, fastened, and installed. Unlike shop drawings, where interest is presented in fabrication interests, erection drawings are geared towards crews on the field and site managers.

Key elements typically found in erection drawings include:

- Member identification and labeling

- Connection methods (welding, bolting, etc.)

- Placement sequencing

- Crane and lifting point indicators

- Field weld symbols and dimensions

- Temporary support or bracing locations

These drawings act as a map for installers, ensuring that the structural elements are placed correctly according to the design. The more comprehensive the erection drawings, the fewer the mistakes during installation, ultimately leading to a smoother and faster project.

The Role of Erection Drawings in Construction

Between an engineering design office and the actual construction site, erection drawings become the main base of reference for the steel erection teams since they provide exact, step-by-step instructions that leave little room for misinterpretation.

The following are ways that erection drawings ensure the success of a project:

- Streamlined Communication: They normalize the exchange of information between stakeholders—engineers, detailers, site supervisors, and installers—minimizing miscommunication. Learn more about BIM coordination.

- Sequencing and Logistics: Accurate ordering of the sequence of steel erection can be achieved by well-formulated erection drawings. See how steel detailing and erection sequencing help with logistics.

- Compliance with Design Intent: They ensure that on-site construction reflects the structural intent of the architecture and engineering design.

Erection drawings, in short, make sense of complex steel construction, reinforce safety rules, and enable field squads to work efficiently under stringent deadlines.quired to work under stringent deadlines.

Benefits of Detailed Erection Drawings for On-Site Teams

High-quality erection drawings are not just helpful—they are essential for maintaining site efficiency and avoiding costly setbacks. Here’s how they benefit construction teams in real-world scenarios:

1. Faster Installation and Assembly

When crews have access to clear and detailed erection drawings, they spend less time interpreting instructions and more time executing them. These drawings eliminate guesswork by showing exactly where each member goes, how it should be connected, and in what sequence. This reduces downtime and keeps the installation process moving smoothly.

2. Minimized Errors and Rework

Errors in steel erection can be expensive and dangerous. Inaccurate placements or misaligned components often result from vague instructions or missing information. Detailed erection drawings reduce these risks by providing precise dimensions, connection details, and positioning information—ensuring each element is placed correctly the first time.

3. Improved Safety Measures

Safety is paramount on every construction site. Erection drawings help identify lifting points, crane paths, and temporary bracing requirements. This foresight allows teams to plan safer lifts, reduce congestion around work areas, and avoid hazardous improvisation. With safety details built into the drawings, crews can focus on execution without unnecessary risks.

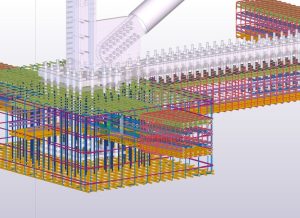

Integration with BIM and 3D Modeling

The evolution of construction technology has transformed how erection drawings are created and utilized. Through Building Information Modeling (BIM) and 3D visualization tools, detailers can now produce far more intuitive and interactive erection drawings.

Here’s how BIM enhances the process:

- Visual Clarity: 3D models help site crews understand complex connections and spatial relationships, which are often difficult to convey in 2D.

- Clash Detection: BIM-integrated erection drawings allow project teams to identify and resolve conflicts before components arrive on-site.

- Improved Collaboration: Changes made to the model are automatically reflected in updated erection drawings, ensuring all teams are working with the latest information.

- Digital Accessibility: Cloud-based platforms allow teams to access erection drawings on tablets or mobile devices directly at the job site, eliminating the need for printed plans.

By integrating BIM and digital workflows, construction teams can elevate the quality, clarity, and responsiveness of their erection drawings, leading to more seamless site execution.

Challenges of Poor or Incomplete Erection Drawings

While high-quality erection drawings support smooth project execution, poor or incomplete ones can cause chaos on-site. The lack of clarity or missing details can snowball into costly consequences:

- Project Delays: Without clear installation instructions, construction teams are forced to halt work and seek clarification, delaying progress and disrupting the overall schedule.

- Increased RFIs and Change Orders: Missing information often leads to a surge in RFIs and unplanned change orders, burdening both the field team and the design office.

- Higher Labor and Equipment Costs: Idle cranes, confused crews, and misallocated resources become common when erection drawings are ambiguous.

- Safety Risks: Improper lifting or sequencing due to unclear details can pose serious risks to worker safety.

In short, incomplete or poorly prepared erection drawings can severely compromise construction productivity, quality, and safety. Investing in well-developed documentation from the beginning is not just smart—it’s essential.

Best Practices for Creating Effective Erection Drawings

To ensure the effectiveness of erection drawings, certain best practices must be followed by steel detailers and drafters. These practices help maintain clarity, precision, and usability for field crews:

- Standardize Drawing Formats: Use consistent symbols, legends, and color codes for easy interpretation on-site.

- Include Installation Sequence: Show the order in which components should be erected to avoid assembly issues or clashes.

- Incorporate Safety and Handling Information: Mark lifting points, bracing requirements, and access zones.

- Align with Fabrication Drawings and 3D Models: Ensure consistency across all drawings to avoid confusion.

- Field Verification and Review: Coordinate with site managers and installers during the planning phase to validate the practicality of the erection drawings.

By following these principles, the final set of erection drawings becomes an essential tool for real-time construction decisions and proactive issue resolution.

Conclusion

In structural steel construction, success hinges on communication, coordination, and clarity. Erection drawings are the core of all three. These technical documents serve as the foundation for precise, safe, and efficient on-site assembly.

From guiding crane operations to reducing rework and delays, the benefits of detailed erection drawings cannot be overstated. Investing in their quality early in the project lifecycle delivers measurable advantages in speed, safety, and cost-effectiveness.

For any contractor, project manager, or construction team aiming to elevate on-site performance, prioritizing top-tier erection drawings is not an option—it’s a necessity.