In construction, accuracy, safety, and cost control are very important. One thing that makes sure everything is strong and safe is rebar detailing. Rebar is the steel used to reinforce concrete. When you use Building Information Modeling (BIM), it makes the job even better. Let’s see how rebar detailing and BIM work together to help build faster and better.

What is Rebar Detailing?

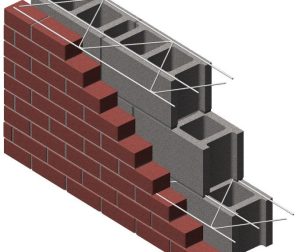

Rebar detailing is about making exact plans for the steel bars that go inside concrete. These plans show where to place the steel bars, how big they should be, and what shape they need to take. If the rebar is not placed right, the concrete structure might not be strong.

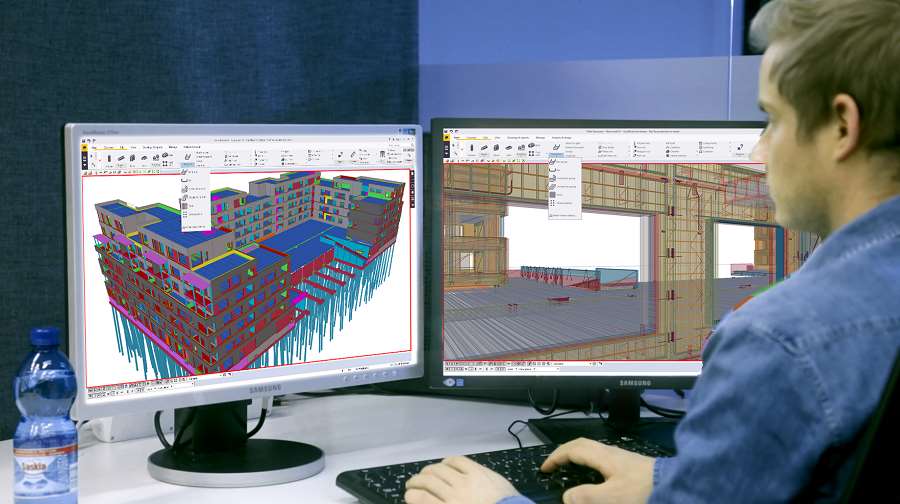

Before, rebar detailing was done by hand. But now, we use computers to make the plans. When you add BIM to this, it helps even more. BIM helps to reduce mistakes and makes things go faster.

What is BIM?

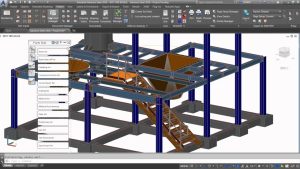

BIM stands for Building Information Modeling. It is a digital model of a building project. BIM shows everything about the project, like the materials, costs, and how everything fits together. The goal of BIM is to make it easy for everyone to work together. Engineers, architects, and contractors can all look at the same model. This helps them make the right choices.

When you add rebar detailing to BIM, you get a very clear view of where the rebar goes. This makes construction quicker and more accurate.

How Does BIM Help with Rebar Detailing?

BIM helps with rebar detailing in several ways:

1. Better Accuracy

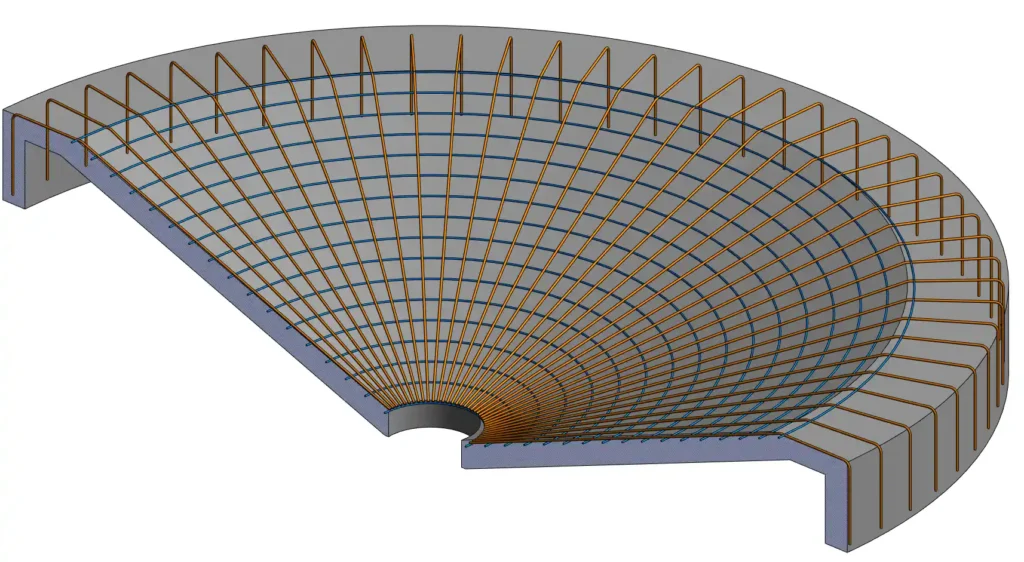

With BIM, you can create a 3D model of the rebar placement. This makes it easier to see if everything is in the right spot. With accurate models, there are fewer mistakes and less rework.

2. Clash Detection

Sometimes, other systems like pipes or electrical wires can get in the way of the rebar. BIM can find these problems before construction starts. This saves time and money by fixing issues early. Learn more about 3D Rebar Modeling here.

3. Easier Collaboration

BIM helps everyone on the team see the same model. This makes it easier for architects, engineers, and contractors to work together. They can fix any problems quickly and stay on the same page.

4. Saving Money

BIM helps figure out exactly how much rebar is needed. This reduces waste. The team can also get the right amount of materials at the right time. This saves money.

5. Faster Work

Since everything is clear in the BIM model, work can move faster. There is no need to stop and fix mistakes. The process becomes quicker, and the project finishes faster.

Benefits of Using BIM with Rebar Detailing

Here’s how BIM with rebar detailing makes construction better:

| Benefit | What It Means |

| Stronger Structures | The rebar will be placed exactly right, making the building stronger. |

| Code Compliance | BIM helps make sure the rebar follows building rules and standards, avoiding problems later. |

| Fewer Mistakes | BIM finds problems early, so you don’t have to fix them on-site. This saves time and money. |

| Instant Access to Data | Everyone can see the latest information and make decisions faster. |

| Less Waste | BIM helps use the right amount of rebar, reducing material waste and saving money. |

Real-World Use of BIM for Rebar Detailing

Better Planning

With BIM, you can see exactly where the rebar goes. If something needs to change, it’s easy to fix. This makes planning easier and faster.

Teamwork

BIM lets everyone look at the same model. This helps all the team members—engineers, contractors, and architects—work together. They can find problems and solve them before construction starts.

Save Time and Money

BIM helps reduce mistakes, which means work goes faster. It also makes sure the right materials are used, so there is less waste. All of this saves time and money.

What to Know Before Using BIM for Rebar Detailing

If you want to use BIM for rebar detailing, keep these things in mind:

1. Pick the Right Software

There are many kinds of BIM software. Choose the one that works best for your project. It should be easy to use for rebar detailing.

2. Train Your Team

BIM works best when people know how to use it. Make sure your team knows how to work with both rebar detailing and BIM software.

3. Use Collaboration Tools

BIM works best when everyone can access it. Make sure the tools allow everyone to see and edit the model at the same time. This helps the team stay on track.

Conclusion

Rebar detailing and BIM work great together. By making everything clear, accurate, and easy to manage, you can build faster and safer. BIM helps find problems early, saves money, and speeds up the whole construction process. If you want to make your construction projects better, using BIM with rebar detailing is the way to go.

Here are 5 major FAQs related to the topic of Rebar Detailing and BIM Integration:

1. What is the role of rebar detailing in construction projects?

Rebar detailing is essential in ensuring the structural integrity of concrete constructions. It involves creating precise drawings and specifications for the placement, size, and shape of the reinforcing steel bars (rebar) used in concrete structures. Proper rebar detailing ensures the correct positioning of rebar, which is crucial for the structure’s strength and stability. This process is especially important in large-scale projects like bridges, high-rise buildings, and dams.

2. How does BIM improve rebar detailing accuracy?

Building Information Modeling (BIM) enhances the accuracy of rebar detailing by allowing the creation of detailed 3D models that represent the rebar placement within the structure. These models help visualize the entire construction process, ensuring that the rebar is placed accurately according to design specifications. BIM reduces errors, clashes, and misunderstandings, ensuring that the rebar fits perfectly within the overall design of the building.

3. What are the key benefits of integrating BIM with rebar detailing?

Integrating BIM with rebar detailing offers several key benefits:

- Improved accuracy: Detailed 3D models help reduce mistakes in rebar placement.

- Clash detection: BIM can identify potential conflicts between rebar and other systems (such as plumbing or electrical), preventing costly rework.

- Cost efficiency: Precise modeling helps optimize the use of materials, reducing waste and lowering overall costs.

- Faster construction: BIM enables efficient planning and collaboration, leading to quicker execution of tasks and faster project completion.

4. How does BIM help with clash detection in rebar detailing?

BIM’s clash detection feature is an invaluable tool in rebar detailing. It automatically identifies conflicts between the rebar and other systems within the building, such as electrical conduits, pipes, or HVAC systems. This early detection helps resolve potential issues before construction begins, reducing the need for costly rework and ensuring that all building components fit together seamlessly.

5. Can BIM be used for both 2D and 3D rebar detailing?

Yes, BIM can be used for both 2D and 3D rebar detailing. While 2D detailing involves traditional drawings of rebar placement, 3D BIM models provide a more detailed and interactive representation of the rebar in the context of the entire structure. 3D models allow for better visualization and more precise calculations, which are essential for large and complex projects. By combining both 2D and 3D BIM methods, contractors can ensure greater accuracy and efficiency in the rebar installation process.