Successful implementation of projects thus relies on the clarity of information contained in drawings. They each play a crucial role in the architectural, structural, and MEP design process, advising on the manufacture and assembly of parts. Under these considerations, contractors, engineers and clients are usually confused on the terms when they are used loosely.

This blog will examine the main features of workshop drawings as compared to fabrication shop drawings, the significance of their difference at construction and why it is important for one to note that from a construction purpose for avoidance of delays and rework costs.

What Are Shop Drawings?

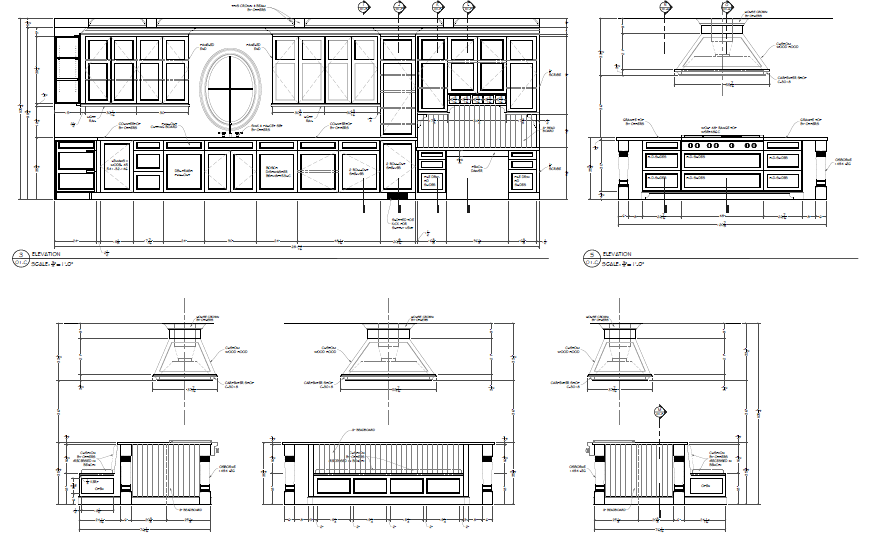

Let’s begin by making it clear the main question:<< What is a shop drawing? Essentially, shop drawings are all inclusive directions produced by contractors, subcontractors, manufacturers or fabricators that explain the process of fabrication, assembly or installation of specific building elements.

Key features of construction shop drawings include:

- Representation of components such as HVAC ducts, piping, electrical systems, windows, and trusses.

- Precise dimensions, materials, and installation details that align with design intent.

- Coordination with architectural and structural plans for compatibility.

Understanding what shop drawings are matters because they enable a clear association between the plans for a project and on-site implementation. If shop drawings were ignored, then the fabrication and installation crews would lack the assurance required to perform their task safely.

What Are Fabrication Drawings?

As opposed to this, fabrication shop drawings carry the level of detail even deeper. They explain the finer points of what is needed for the production or the construction of a part or a system. Fab drawings are used mostly in manufacturing and assembly shops; because of this, they bear the name.

Fabrication drawing services support contractors by converting architectural and engineering plans into shop-ready documentation. These specialized services help teams create spools, assemblies, CNC-ready drafting plans, DXF files, and installation diagrams, all designed for true-to-size production.

Here’s what characterizes fabrication drawings:

- Specific focus on how a component will be manufactured or assembled.

- Include welds, bolt locations, hole sizes, bending details, and finishes.

- Often used for steel shop drawings and custom equipment fabrication.

Workshop Drawings: The Backbone of Trade-Level Detailing

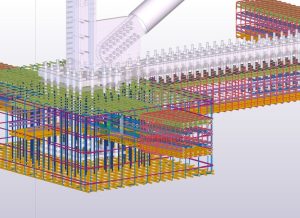

Workshop drawings serve as the blueprint that guides on-site trades and fabrication teams through every phase of construction. Unlike high-level engineering drawings, workshop drawings break down the project into trade-specific deliverables such as rebar placement diagrams, joinery details, steel member schedules, and precise MEP routing plans.

They are essential for fabrication, assembly, material procurement, and inspection processes. Knowing the true workshop drawing meaning helps teams maintain consistency, adhere to design standards, and eliminate miscommunication that could otherwise lead to rework or delays.

Key Differences Between Shop Drawings and Fabrication Drawings

Shop drawings and fabrication drawings are critical to construction and manufacturing efforts but perform distinct roles, are implemented by different roles, and require varying degrees of detail and operation. By acknowledging these differences, collaboration is better facilitated, there are fewer errors, and it’s ensured all parties concerned are in sync.

Understanding fabrication drawings vs shop drawings helps teams clarify responsibilities and avoid workflow confusion. The below specifies important differences between shop drawings and fabrication drawings, indicating their parts in the general construction process:

1. Purpose and Function

- Shop Drawings: These guides give a clear diagram of how each component will be fitted in the job site. They act as a visual guide that helps contractors to make installs compatible with architectural and engineering designs. In essence, a shop drawing is a manual that details how the components of a building’s assembly fit into this larger picture.

- Fabrication Drawings: These go deeper into the actual manufacturing process. Fabrication drawings include details needed to physically build or assemble the part in a workshop or factory. Whether it’s custom ductwork or steel shop drawings, these documents focus on “how” a component will be fabricated rather than “where” it fits.

2. Level of Detail

- Shop Drawings typically include:

- Dimensions

- Material specifications

- Connection and placement diagrams

- Installation instructions

- Coordination with other systems (HVAC, plumbing, electrical)

- These are more about coordination and compliance with design intent.

- Fabrication Drawings usually contain:

- Detailed measurements (to millimeter precision)

- Welding symbols, bolt sizes, hole locations

- Tolerances and machining requirements

- Assembly sequences

- Surface finishes and material treatments

- These are technical blueprints used by fabricators, machinists, and welders.

3. Audience

- Shop Drawings are intended for:

- General contractors

- Architects

- Engineers

- On-site installers

- Project managers

- Fabrication Drawings are used by:

- Manufacturing teams

- Machine operators

- Fabricators and welders

- Quality assurance inspectors

- Suppliers of prefabricated systems

This distinction ensures that each team receives the appropriate level of detail to execute their responsibilities accurately.

4. Creation and Workflow

- Shop Drawings are usually produced by subcontractors, MEP engineers, or detailing companies during the coordination phase of a project. They’re often derived from architectural and structural drawings and are crucial for approval and permit processes.

- Fabrication Drawings are developed post-approval of shop drawings, often by vendors or manufacturers. These are more technical and guide actual production, especially when working with fab drawing specialists or fabrication drawing services.

5. Use Cases in Real Projects

- Construction Shop Drawings:

- Routing of HVAC systems through a building

- Placement of electrical panels or sprinkler systems

- Coordination between plumbing and structural elements

- Fabrication Shop Drawings:

- Manufacturing of steel beams, brackets, or supports (steel shop drawings)

- Custom sheet metal duct fabrication

- Assembly instructions for mechanical skids or prefab wall panels

In complex builds, both types of drawings are used in tandem—shop drawings help coordinate installations, while fabrication drawings ensure parts are built to spec.

6. Software and Standards

- Shop Drawings often utilize BIM (Building Information Modeling) software for coordination and clash detection.

- Fabrication Drawings rely more heavily on CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) tools that adhere to industry standards like ISO, ANSI, or AWS.

Why Both Are Crucial in Construction Projects

In construction, precision is non-negotiable. That’s why both workshop drawings and fabrication shop drawings are indispensable. The debate of fabrication drawings vs shop drawings often arises during BIM coordination meetings.

Benefits of using both:

- Accuracy: Avoid costly on-site errors by having exact specifications for both production and placement.

- Coordination: Ensure that fabricated components match the construction requirements precisely.

- Compliance: Meet design codes, standards, and approval processes efficiently.

From pre-engineered steel structures to intricate MEP systems, proper use of construction shop drawings and fabrication drawings ensures projects stay on schedule and on budget.

How to Ensure High-Quality Shop and Fabrication Drawings

The comparison of fabrication drawings vs shop drawings is crucial for project managers, engineers, and contractors because both play distinct roles. While they are often confused, each serves a unique purpose within the construction documentation hierarchy.

To ensure the effectiveness of your fabrication shop drawings or shop drawings, consider the following best practices:

- Collaborate early with design and fabrication teams.

- Use BIM-integrated workflows to generate clash-free construction shop drawings.

- Work with experienced drafters who specialize in fab drawing services.

- Ensure proper document version control and approval workflows.

This minimizes errors, delays, and miscommunication between your team, vendors, and installers.

Conclusion: Clear Drawings Equal Clear Execution

While they may seem similar at first glance, shop drawings and fabrication drawings serve distinct but complementary purposes in the construction process. Together, they bridge the gap between design and execution, ensuring that what gets built matches what was envisioned. However, the true workshop drawing meaning emphasizes precision, coordination, and clarity in construction workflows.Whether you’re an architect, contractor, or fabricator, investing in quality workshop drawings and fabrication drawing services will always pay off in time, cost, and construction quality.