Building strength along durability is determined by the precise design of components and their correct assembly methods. Rebar stands as the essential element for maintaining structure stability because engineers embed it inside concrete through reinforcing steel techniques. Putting rebar inside structures by itself does not produce sufficient results. The rebar detailing requires both detailed planning and exact specifications regarding rebar positions because it determines the effectiveness of rebar performance.

Engineers create detailed drawings as part of rebar detailing to show the exact place and manner that reinforcement bars should be placed inside concrete building structures. Whether you’re working on a residential building, commercial property, or infrastructure project, the definition of rebar and its proper placement is crucial.

What is Rebar Detailing?

The term rebaring meaning the process that generates detailed accurate plans which establish rebar placement criteria for concrete construction elements. Construction plans present detailed drawings or 3D models that show team members the correct bar reinforcement placement positions so concrete can perform optimally under stress conditions.

Definition of Rebar Detailing

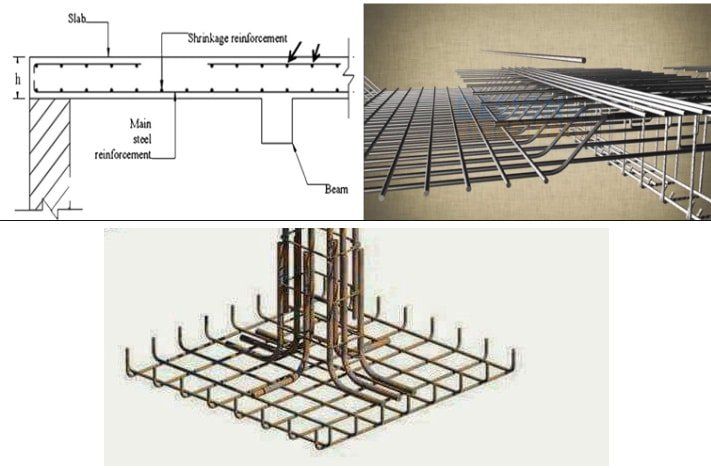

The core aspect of rebar detailing is to establish the exact positioning together with the dimensions and shapes for rebar placement inside structures. The steel type of rebars serves as concrete reinforcing elements because concrete maintains strong compression abilities yet demonstrates weak resistance to tension forces. The main reason for adding rebar into concrete structures is to enable resistance against bending and tension forces and shear stress, which maintains structural stability during long-term usage.

Key Components of Rebar Detailing:

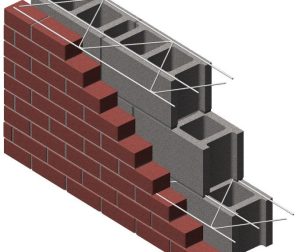

- Rebar Type and Size: The type of rebar (e.g., deformed or smooth) and its size (diameter and grade) are specified in rebar detailing. Different areas of a building might require different types of rebar, depending on the expected loads and stress.

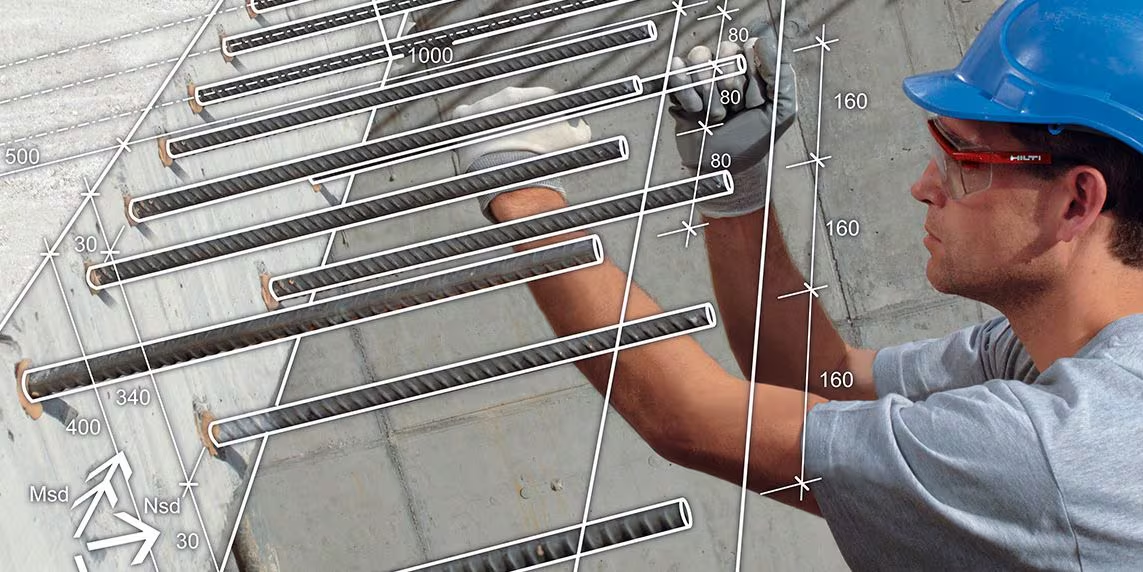

- Spacing: The distance between bars plays a vital role in achieving consistent strength throughout the entire structure. A structure becomes weaker when bars are either positioned too close together or spaced too widely since this leads to the inconsistent distribution of loads.

- Bend and Hook Details: For the integration of rebar into concrete structural corners and angles, contractors often need to bend the bars. Safety instructions for the bending radius and bend length, together with hook positioning, are provided in the detailed specifications.

- Location and Layout: Detailed drawings outline how to place each bar so reinforcement can be allocated at every required spot, including beams, columns, slabs, or foundations within the concrete pour.

The Role of Rebar in Concrete Structures

Rebar detailing remains crucial because it enables full comprehension of steel bars’ purposes in concrete structures. The rebar detailer plays an essential role in ensuring the correct implementation of rebar, as they create detailed drawings and specifications for where each bar should go. The high strength of concrete under compression fades in tension and shear conditions.

Types of Rebar and Their Uses:

- Mild Steel Rebar (Grade 60): It is the preferred choice for construction industries operating residential and commercial works due to its combination of affordability and suitable strength outcome.

- Epoxy-Coated Rebar: Functions as an optimal solution for structures built close to the coast or placed in bridge construction because it withstands corrosion attacks.

- Stainless Steel Rebar: This rebar serves projects built in corrosive conditions, especially chemical plants and marine structures.

- High-Strength Rebar: Serves as a construction material designed to withstand tension loads that find applications during significant infrastructure works of tall buildings.

Why Rebar Detailing is Crucial for Structural Integrity

The proper detailing of rebar additives gives concrete structures their fundamental attributes of safety alongside strength and enduring quality. The bdr meaning in steel design comes into play, referring to the bending, distribution, and reinforcement processes that are crucial for ensuring the strength and longevity of the structure. The overall structural safety of buildings and infrastructure becomes severely jeopardized when rebar details are not accurately executed.

Here are some reasons why rebar detailing is so crucial for structural integrity:

Ensuring Proper Load Distribution

The main purpose of rebar is its distribution of forces over the structural elements. Rebar detailing determines how rebar material should be positioned at specific locations while maintaining proper spacing to handle these loads. When buildings undergo structural stress, beams and columns require exact placement so the load has adequate support to prevent failure.

Preventing Cracks and Structural Failure

Tension and bending forces easily cause concrete materials to crack severely. Rebar reinforcement, when detailed correctly, enables control of cracks because it supports concrete properly throughout. Rebar detailing establishes how reinforcing steel works with concrete while specifying bend radii and spacing, which directly impacts the structural capability to handle different kinds of stress. Accurate detailing reduces the probability of structural weaknesses and failure due to cracks, shrinkage, and irregular force distribution.

Compliance with Building Codes and Standards

Every country and region has specific building codes that dictate how structures should be reinforced and how the rebar should be placed to ensure safety. Rebar detailing helps ensure that these codes are met, reducing the risk of non-compliance and potential legal issues. Tall buildings require meticulous detailing reinforcement to distribute vertical and horizontal loads effectively and ensure structural stability.

Optimizing Material Use

Accurate rebar detailing allows for the efficient use of materials. By specifying the exact amount and size of rebar needed, rebar detailing helps prevent waste during construction. It ensures that the right quantities of rebar are ordered and that there is no surplus or shortage during the construction process. This not only reduces costs but also helps the project stay within budget.

Safety and Durability

Rebar detailing contributes significantly to the long-term safety of the building or infrastructure. Properly detailed rebar layouts help minimize the risk of catastrophic failures, which can endanger lives and result in costly repairs. Additionally, deviating from the rebar software-generated design plans or ignoring structural specifications can result in a building that does not meet safety standards, leading to legal and structural consequences.

Conclusion

Rebar detailing is an integral part of the construction process that directly influences the safety, durability, and success of any building project. Whether it’s a residential home, a high-rise building, or a complex infrastructure project, proper rebar detailing ensures that the reinforcement bars are placed and sized correctly to withstand the forces that the structure will face over its lifetime. By following best practices and leveraging advanced technologies like 3D modeling and automation, rebar detailing professionals can help prevent costly mistakes, delays, and structural failures.

By understanding the importance of rebar detailing and investing time and resources into this crucial step, construction teams can achieve long-lasting, high-quality results that meet both safety standards and client expectations.